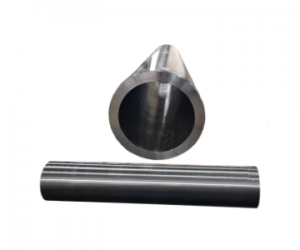

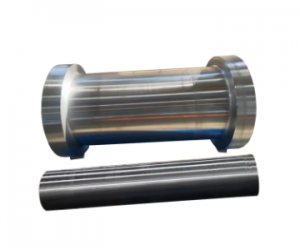

Tuubada caloosha

Faahfaahinta badeecada:

Goobta asalka ah: Shanxi

Magaca Astaamaha: DHDZ

Shahaadaynta: ASME, JIS, GB, GB, BB, EN, SASS, ASTM A370, API 6B, API 6C

Warbixinta Imtixaanka: MTC, HT, UT, UT, UT, UT, MPT, Warbixinta cabirka, imtixaanka muuqaalka, EN10204-3, EN10204-3.2

Tilmaanta: Tupp / PED 2014/68 / EU

Tirada ugu yar ee amarrada: 1 gabal

Xirmooyinka Gaadiidka: kiiska Plywood

Daweynta Dusha sare: Daaweynta

Qiimaha: Wadahadalka

Awoodda Soo-Saarka: 20000 tan / sanadka

| Waxyaabaha walxaha | C | Mn | P | S | SI | Cr | NI | Mo | Cu | N |

| A182 F51 | ≤ 0.030 | 2.0 | ≤ 0.030 | ≤ 0.020 | <0.80 | 21-23 | 4.5-6.5 | 2.50-3.50 | / | 0.20-0.24 |

| A182 F53 | ≤ 0.030 | ≤ 1.20 | ≤ 0.035 | <0.020 | <0.80 | 24-26 | 6.0-8.0 | 3-5 | <0.50 | 0.24-0.32 |

| 34crimo6 | 0.3-0.38 | 0.5-0.8 | ≤ 0.025 | ≤ 0.035 | ≤ 0.4 | 1.3-1.7 | 1.3-1.7 | 0.15-0.3 | / | / |

| 16mnd | 0.13-0.20 | 1.2-1.6 | ≤0.030 | ≤0.030 | 0.17-0.37 | ≤0.30 | ≤0.30 | / | / | / |

| 20mnmo | 0.17-0.23 | 1.1-1.4 | ≤0.025 | ≤0.015 | 0.17-0.37 | ≤0.030 | ≤0.030 | 0.20-0.35 | / | / |

| 20mnnono | 0.16-0.23 | 1.2-1.5 | ≤0.035 | ≤0.035 | 0.17-0.37 | / | / | 0.45-0.60 | / | 0.20-0.45 |

| Hantida farsamada | Die. (Mm) | Ts / RM (MPA) | Ys / rp0.2 (MPA) | El / A5 (%) | Ra / Z (%) | Qaybsanaan | Tamarta saameynta | Dhugeeyo |

| A182 F51 | / | ≥620 | ≥450 | ≥25 | > 45 | V | ≥45J | / |

| A182 F53 | / | ≥800 | 550 | ≥15 | / | V | / | 310 |

| 34crimo6 | Ф12.5 | ≥785 | / | ≥11 | ≥30 | V | ≥71J | / |

| 16mnd | Ф10 | 470-630 | ≥345 | ≥21 | / | V | / | / |

| 20mnmo | Ф10 | ≥605 | ≥475 | ≥25 | / | V | ≥180 | / |

| 20mnnono | Ф10 | ≥635 | ≥490 | ≥15 | / | U | ≥47 | 187-229 |

Qaabsocodyada Soo-Saarka:

Ku-meel-gaadhkan bir ah (tijaabada kiimikada ee kululaynta (UT, MTECTES) → Kormeerka (UT, Cabbirka farsamada) → Qulqulka (US, cabirka cajiibka ah) → QIIMADAHA THEST (cabir) → xirxiran iyo calaamadeyn (shaabad bir ah, calaamadda) → Shixnadaha kaydinta

Faa'iidada:

Guryaha farsamada wanaagsan,

Dulqaadashada sumcadda sare,

Xakamee nidaamka wax soo saarka si adag,

Qalabka Soo-Saar ee Soosaarka iyo Qalabka Kormeerka,

Shaqsiyad farsamo oo heer sare ah,

Soo saar cabirro kaladuwan oo ku saleysan shuruudaha macaamiisha,

Fiiro gaar ah u yeelo ilaalinta xirmada,

Adeeg buuxa oo tayo buuxda leh.

Warshadaha Codsiga:

Qalabka macdanta, qalabka macdanta, weelasha macdanta, maraakiibta dusha sare, qalabka kor u qaadista, mashiinka dhismaha, jiilka korantada, iwm.