Baararka been abuurka ah

Soo saaraha Dhimashada Forgings ee Shiinaha ka furan

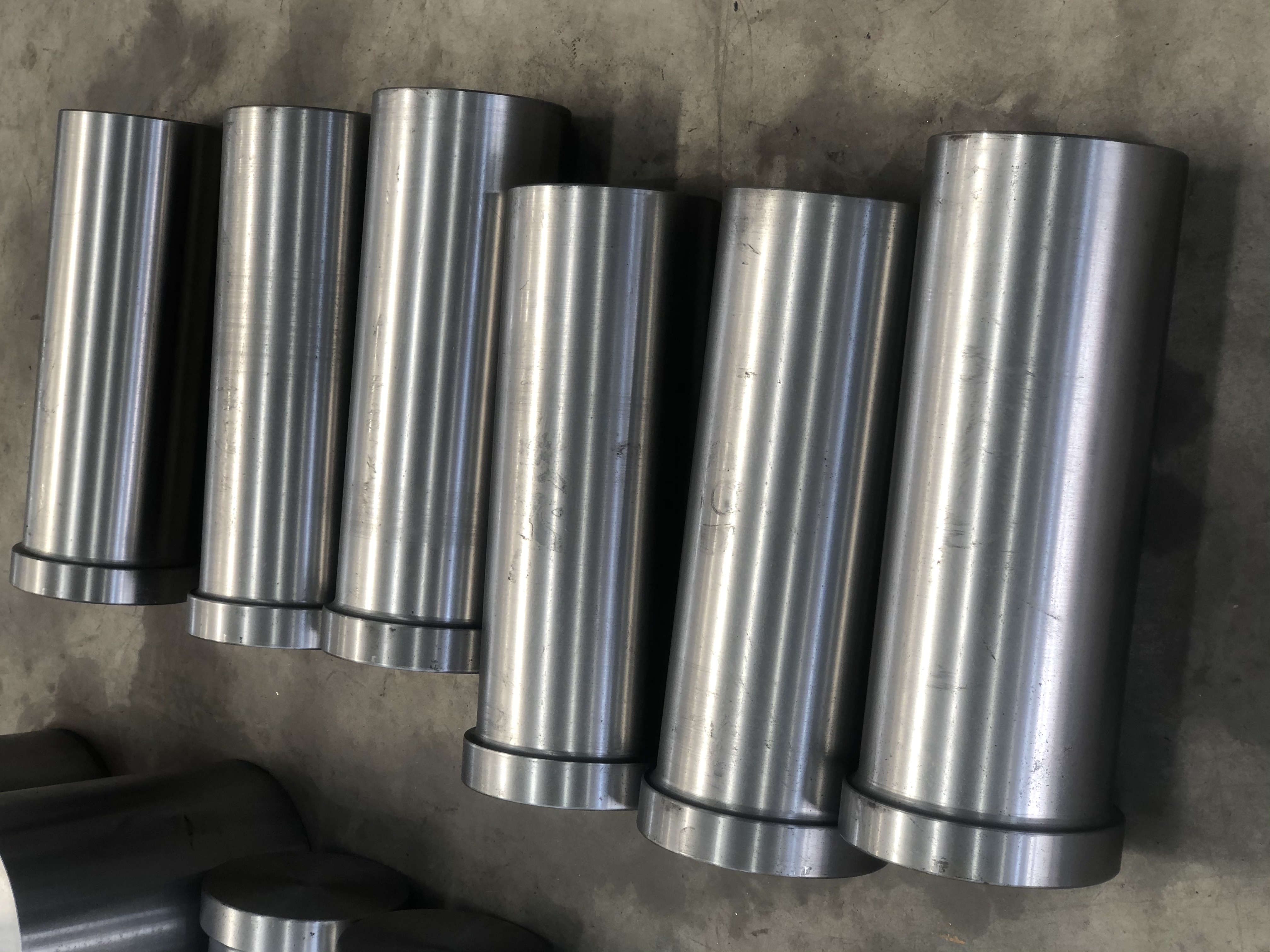

Baararka been abuurka ah

Waxyaabaha caadiga ah ee la isticmaalo: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 |42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30NiCrMo12 |22NiCrMoV12

MEESHA BAAR LA BEDESHAY

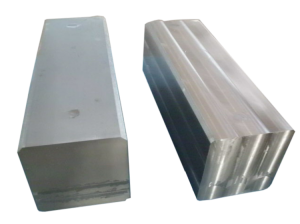

Baararka wareega, baararka labajibbaaran, baararka fidsan iyo baararka hex. All Metals waxay leeyihiin awood been abuur ah si ay u soo saaraan baararka ka mid ah noocyada alloy ee soo socda:

● birta daawaha ah

● Birta kaarboonka

● Birta aan la taaban karin

AWOODAHA BAAR LA BEJARAY

ALLOY

MAX BILAASH

MAX CULUS

Kaarboon, Alloy

1500mm

26000 kg

Birta Aan Lahayn

800mm

20000 kg

AWOODAHA BAAR LA BEJARAY

Dhererka ugu badan ee baararka wareegyada been abuurka ah iyo baararka hex waa 5000 mm, oo leh ugu badnaan 20000 kgs.

Dhererka iyo ballaca ugu badan ee baararka fidsan iyo baararka labajibbaaran waa 1500mm, oo leh ugu badnaan 26000 kgs.

A bar been abuur ah ama bar duubanwaxaa lagu soo saaraa qaadashada xinjir iyobeen abuurashoilaa inta ay le'eg tahay, guud ahaan, laba guri oo iska soo horjeeda ayaa dhinta. Biraha la been-abuuray waxay u muuqdaan kuwo ka xoog badan, adag oo ka adkeysi badan qaababka la shubay ama qaybaha la farsameeyay. Waxaad ka heli kartaa qaab-dhismeed hadhuudh la sameeyay oo dhan dhammaan qaybaha foornooyinka, kordhinta awoodda qaybaha u adkeysiga dagaalka iyo xidhashada.

Shanxi DongHuang Wind Power Flange Manufacturing Co., LTD., Sida ISO soo saaraha been abuurka shahaadaysan ka diiwaan gashan, waxay dammaanad qaadaysaa in been-abuurka iyo/ama baararka ay yihiin kuwo isku mid ah oo tayo leh oo aan lahayn cillado waxyeello u leh sifooyinka farsamada ama mashiinnada qalabka.

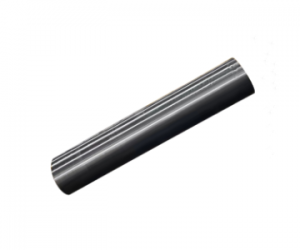

Kiis:

Heerka BirtaEN 1.4923 X22CrMoV12-1

Qaab dhismeedkaMartensitic

| Halabuurka kiimikada% birta X22CrMoV12-1 (1.4923): EN 10302-2008 | ||||||||

| C | Si | Mn | Ni | P | S | Cr | Mo | V |

| 0.18 - 0.24 | ugu badnaan 0.5 | 0.4 - 0.9 | 0.3 - 0.8 | ugu badnaan 0.025 | ugu badnaan 0.015 | 11 - 12.5 | 0.8 - 1.2 | 0.25 - 0.35 |

Codsiyada

Warshada Korontada, Injineerinka Mashiinka, Korontada.

Qaybaha xadhkaha tuubooyinka, kululeeyaha uumiga iyo marawaxadaha.

Foomka keenista

Baar wareeg ah, Gawaarida Forgings duuban, baararka wareega ee caajisay, X22CrMoV12-1 Baar been abuur ah

Cabbirka: φ58x 536L mm.

Been Abuur (Shaqo Kulul) Barobar

Alaabta waxaa lagu shubaa foornada oo la kululeeyaa. Marka heerkulku gaaro 1100 ℃, birta ayaa la been abuuran doonaa. Waxa loola jeedaa hab-raac kasta oo makaanik ah oo qaabeeya biraha soo saaraya hal ama in ka badan oo dhinta, tusaale ahaan dildillaaca furan/xidhan, kaxaynta, duubista, iwm. Inta lagu jiro hawshan, heerkulka birta ayaa hoos u dhacaya. Marka ay hoos u dhacdo 850 ℃, birta waa la kululayn doonaa mar kale. Ka dibna ku celi shaqada kulul heerkulka sare (1100 ℃). Saamiga ugu yar ee saamiga shaqada kulul laga bilaabo ingot ilaa billet waa 3 ilaa 1.

Habka Daawaynta Kulaylka

Ku shub qalabka daawaynta kulaylka hore ee mashiinada daawaynta kulaylka furance. Kuleyl ilaa heerkul ah 900 ℃. Ku hay heerkulka 6 saacadood 5 daqiiqo. Daminta saliidda iyo xanaaqa 640 ℃. Kadibna hawo qabow.

Qalabka makaanikada ee X22CrMoV12-1 bar been abuur ah (1.4923).

| Rm- Xoog xajin (MPa) (+QT) | 890 |

| Rp0.20.2% xoogga caddaynta (MPa) (+QT) | 769 |

| KV- Tamarta Saamaynta (J) (+QT) | -60° 139 |

| A Min. dheereynta jabka (%) (+QT) | 21 |

| Qalafsanaanta brinell (HBW): (+A) | 298 |

Dhibcooyin kasta oo agab ah, oo aan ahayn kor ku xusan, waa la been-abuuri karaa sida ku cad shuruudaha macmiilka.