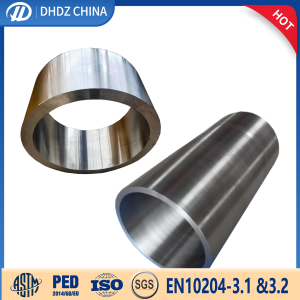

Saxanadaha Birta laga been abuurtay

Faahfaahinta Alaabta:

Meesha Asal ahaan: Shanxi

Magaca astaanta: DHDZ

Shahaadooyinka: TUV/ PED 2014/68/EU

Warbixinta Imtixaanka: En10204-3.1, MTC, EN10204-3.2

Dulqaadka Been Abuurka: +/- 0.5mm

Tirada Dalabka ugu Yar:1 gabal

Xidhmada Gaadiidka: Kiiska Plywood/Brandrith

Qiimaha: Waa laga xaajoon karaa

Awoodda Wax-soo-saarka: 2000 Tan/Sanad

| Walxaha walxaha | C | Mn | P | S | SI | Cr | NI | Mo | Cu | N |

| 4130 | 0.33 | 0.7 | <0.025 | <0.025 | <0.35 | 0.8-1.0 | <0.5 | 0.15-0.25 | / | / |

| A182 F53 | ≤ 0.030 | ≤ 1.20 | ≤ 0.035 | <0.020 | <0.80 | 24-26 | 6.0-8.0 | 3-5 | <0.50 | 0.24-0.32 |

| F6Mn | ≤ 0.05 | 1.0 | ≤ 0.03 | ≤0.03 | ≤0.60 | 11-14 | 3.5-5.5 | 0.5-1 | / | / |

| C45 | 0.42-0.50 | 0.5-0.8 | ≤ 0.035 | ≤ 0.035 | 0.17-0.37 | ≤ 0.25 | <0.5 | / | ≤ 0.30 | / |

| 35NiCrMoV12-5 | 0.30-0.40 | 0.4-0.7 | ≤ 0.015 | ≤ 0.015 | ≤ 0.35 | 1.0-1.4 | 2.5-3.5 | 0.35-0.65 | / | / |

| 20MnMoNo | 0.16-0.23 | 1.2-1.5 | ≤0.035 | ≤0.035 | 0.17-0.37 | / | / | 0.45-0.60 | / | 0.20-0.45 |

| Hantida makaanikada | Dia.(mm) | TS/Rm (Mpa) | YS/Rp0.2 (Mpa) | EL/A5 (%) | RA/Z (%) | Darajo | Saamaynta tamarta | HBW |

| 4130 | Ф10 | :655 | >517 | >18 | >35 | V | ≥20J (-60℃) | 197-23 |

| A182 F53 | / | ≥800 | ≥550 | ≥15 | / | V | / | <310 |

| F6Mn | / | ≥790 | ≥620 | ≥15 | ≥45 | V | / | ≤295 |

| C45 | 12.5 | ≥540 | ≥240 | ≥16 | / | V | / | / |

| 35NiCrMoV12-5 | 12.5 | ≥1100 | ≥850 | ≥8.0 | / | V | / | / |

| 20MnMoNo | Ф10 | ≥635 | ≥490 | ≥15 | / | U | ≥47 | 187-229 |

Hababka wax soo saarka:

Hababka been abuurka xakamaynta tayada socodka: Walxaha ceeriin ee galay bakhaar (tijaabi waxa ku jira kiimikaad) → Goynta → Kululaynta(Tijaabada heerkulka foornada) → Daaweynta kulaylka ka dib foornada ,MT, Visal Diamention, engegnaanshiyaha)→ QT→ Kormeerka machining → Kormeer (cabbir) → Xidhidh iyo calaamadayn(shaambada birta, calaamad)

Faa'iidada:

Sifooyin farsamo oo heer sare ah,

Dulqaadka cabbirka saxda ah ee saxda ah,

Si adag u xakamee habka wax soo saarka,

Qalabka wax soo saarka horumarsan iyo aaladaha kormeerka,

Shakhsi farsamo oo heer sare ah,

Soo saar cabbir kala duwan oo ku salaysan shuruudaha macaamiisha,

U fiirso ilaalinta xirmada,

Adeeg buuxa oo tayo leh.

Warshadaha Codsiga:

Warshadaha farsamaynta cuntada, warshadaynta qalabka, sahayda biyaha iyo bullaacadaha, warshadaha dhismaha maraakiibta, iwm.