I-TUBELISELA IZIMBOLO ZAMAHHALA

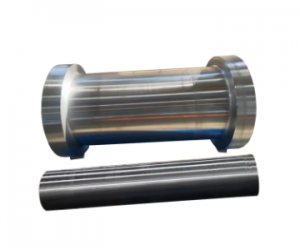

Imininingwane Yomkhiqizo:

Indawo yemvelaphi: SHANXI

Igama lomkhiqizo: DHDZ

Ukuqinisekiswa: ASME, JIS, DIN, GB, BS, EN, AS, SABS, ASTM A370, API 6b, API 6C

Umbiko Wokuhlola: I-MTC, HT, UT, MPT, Disension Report, Visual Test, EN1020404

Ukucaciswa: Tuv / PED 2014/68 / EU

Ubuncane be-oda le-oda: ucezu olu-1

Iphakheji Yezokuthutha: Icala lePlywood

Ukwelashwa okungaphezulu: Ukupholisa

Intengo: Ukuxoxisana

Umthamo Wokukhiqiza: I-20000 Ton / unyaka

| Izinto ezibonakalayo | C | Mn | P | S | SI | Cr | NI | Mo | Cu | N |

| I-A182 F51 | ≤ 0.030 | I-2.0 | ≤ 0.030 | ≤ 0.020 | <0.80 | 21-23 | 4.5-6.5 | 2.50-3.50 | / | 0.20-0.24 |

| A182 F53 | ≤ 0.030 | ≤ 1.20 | ≤ 0.035 | <0.020 | <0.80 | 24-26 | 6.0-8.0 | 3-5 | <0.50 | 0.24-0.32 |

| 34Crnimo6 | 0.3-0.38 | 0.5-0.8 | ≤ 0.025 | ≤ 0.035 | ≤ 0.4 | 1.3-1.7 | 1.3-1.7 | 0.15-0.3 | / | / |

| I-16mnd | 0.13-0.20 | 1.2-1.6 | ≤0.030 | ≤0.030 | 0.17-0.37 | ≤0.30 | ≤0.30 | / | / | / |

| 20mndo | 0.17-0.23 | 1.1-1.4 | ≤0.025 | ≤0.015 | 0.17-0.37 | ≤0.030 | ≤0.030 | 0.20-0.35 | / | / |

| I-20mnmono | 0.16-0.23 | 1.2-1.5 | ≤0.035 | ≤0.035 | 0.17-0.37 | / | / | 0.45-0.60 | / | 0.20-0.45 |

| Impahla yemishini | Dia. (Mm) | I-TS / RM (MPA) | YS / RP0.2 (MPA) | El / A5 (%) | URa / z (%) | Ugch | Umthelela amandla | I-HBW |

| I-A182 F51 | / | ≥620 | ≥40 | ≥25 | > 45 | V | ≥45J | / |

| A182 F53 | / | ≥800 | ≥550 | ≥15 | / | V | / | <310 |

| 34Crnimo6 | Фthela.5 | ≥785 | / | ≥11 | ≥30 | V | ≥71jjjj | / |

| I-16mnd | Ф0 | 470-630 | ≥345 | ≥21 | / | V | / | / |

| 20mndo | Ф0 | ≥605 | ≥475 | ≥25 | / | V | ≥100 | / |

| I-20mnmono | Ф0 | ≥635 | ≥490 | ≥15 | / | U | ≥47 | 187-2299 |

Izinqubo Zokukhiqiza:

Ukwenza inqubo yokulawula ikhwalithi yokulawula: I-Inot yensimbi engavuthiwe ibe yi-warehouse (Hlola okuqukethwe kwamakhemikhali) (ubukhulu) → ukupakisha nokumaka (isitembu sensimbi, uphawu) → Ukuhanjiswa kwesitoreji

Inzuzo:

Izakhiwo ezinhle kakhulu zemishini,

Ukubekezelela okunengqondo okuphezulu,

Lawula inqubo yokukhiqiza ngokuqinile,

Imishini yokukhiqiza ethuthukile namadivayisi wokuhlola,

Ubuntu obuhle kakhulu bezobuchwepheshe,

Khiqiza ubukhulu obuhlukile ngokususelwa kwizidingo zamakhasimende,

Naka Ukuvikelwa Kwephakheji,

Insizakalo ephelele yekhwalithi.

Izimboni Zezicelo:

Imishini yensimbi, imishini yokumbiwa, imikhumbi yakudala, ukuphakamisa imishini, imishini yokwakha, ukukhiqizwa kwamandla, njll.