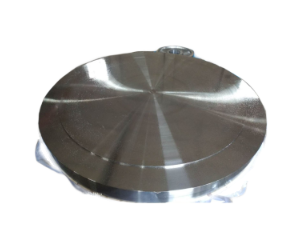

Steel Forged Discs

Imininingwane Yomkhiqizo:

Indawo Yomsuka: Shanxi

Igama lomkhiqizo: DHZ

Izitifiketi: TUV/PED 2014/68/EU

Umbiko Wokuhlola: En10204-3.1, MTC, EN10204-3.2

Ukubekezelela Kokwakha: +/-0.5mm

Ubuncane be-oda lobungako: ucezu olu-1

Iphakheji Yezokuthutha: Ikesi lePlywood/Brandrith

Inani:Kungaxoxiswana

Amandla Okukhiqiza: 2000 Ton/Unyaka

| Izinto ezibonakalayo | C | Mn | P | S | SI | Cr | NI | Mo | Cu | N |

| 4130 | 0.33 | 0.7 | <0.025 | <0.025 | <0.35 | 0.8-1.0 | <0.5 | 0.15-0.25 | / | / |

| I-A182 F53 | ≤ 0.030 | ≤ 1.20 | ≤ 0.035 | <0.020 | <0.80 | 24-26 | 6.0-8.0 | 3-5 | <0.50 | 0.24-0.32 |

| F6Mn | ≤ 0.05 | 1.0 | ≤ 0.03 | ≤0.03 | ≤0.60 | 11-14 | 3.5-5.5 | 0.5-1 | / | / |

| C45 | 0.42-0,50 | 0.5-0.8 | ≤ 0.035 | ≤ 0.035 | 0.17-0.37 | ≤ 0.25 | <0.5 | / | ≤ 0.30 | / |

| 35NiCrMoV12-5 | 0.30-0.40 | 0.4-0.7 | ≤ 0.015 | ≤ 0.015 | ≤ 0.35 | 1.0-1.4 | 2.5-3.5 | 0.35-0.65 | / | / |

| 20MnMoNo | 0.16-0.23 | 1.2-1.5 | ≤0.035 | ≤0.035 | 0.17-0.37 | / | / | 0.45-0.60 | / | 0.20-0.45 |

| Impahla yemishini | I-Dia.(mm) | TS/Rm (Mpa) | YS/Rp0.2 (Mpa) | EL/A5 (%) | I-RA/Z (%) | Inothi | Amandla okuthinta | HBW |

| 4130 | Ф10 | 655 | 517 | >18 | >35 | V | ≥20J(-60℃) | 197-23 |

| I-A182 F53 | / | ≥800 | ≥550 | ≥15 | / | V | / | <310 |

| F6Mn | / | ≥790 | ≥620 | ≥15 | ≥45 | V | / | ≤295 |

| C45 | Ф12.5 | ≥540 | ≥240 | ≥16 | / | V | / | / |

| 35NiCrMoV12-5 | Ф12.5 | ≥1100 | ≥850 | ≥8.0 | / | V | / | / |

| 20MnMoNo | Ф10 | ≥635 | ≥490 | ≥15 | / | U | ≥47 | 187-229 |

Izinqubo Zokukhiqiza:

Inqubo yokufaka ukulawulwa kwekhwalithi yokugeleza: Insimbi yensimbi engaphekiwe ifakwe endlini yokugcina impahla(hlola okuqukethwe kwamakhemikhali) → Ukusika→ Ukushisisa(Ukuhlolwa kwezinga lokushisa kwesithando somlilo) → Ukwelashwa kokushisa ngemva kokubumba(ukuhlolwa kwezinga lokushisa kwesithando somlilo) Khipha isithando somlilo(ukuhlola okungenalutho)→Machining→Ukuhlola(UT ,MT,I-Visal diamention, ubulukhuni)→ QT→ Ukuhlola(UT, izakhiwo eziwumshini, ubulukhuni, usayizi wokusanhlamvu)→ Qeda ukwenza imishini→ Ukuhlola (ubukhulu)→ Ukupakisha nokumaka(isitembu sensimbi, maka)→ Ukuthunyelwa Kwesitoreji

Inzuzo:

Izakhiwo ezinhle kakhulu zemishini,

Ukubekezelela okunembayo okuphezulu,

Lawula inqubo yokukhiqiza ngokuqinile,

Imishini yokukhiqiza ethuthukisiwe nemishini yokuhlola,

Ubuntu obuhle kakhulu bobuchwepheshe,

Khiqiza ubukhulu obuhlukile ngokusekelwe ezidingweni zekhasimende,

Naka ukuvikelwa kwephakheji,

Isevisi egcwele yekhwalithi.

Izimboni zohlelo lokusebenza:

Imboni yokucubungula ukudla, ukukhiqiza imishini, ukuhlinzekwa kwamanzi kanye ne-drainage, imboni yokwakha imikhumbi, njll.