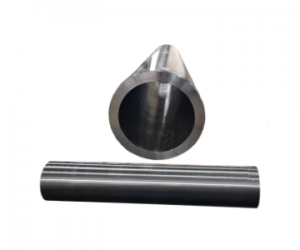

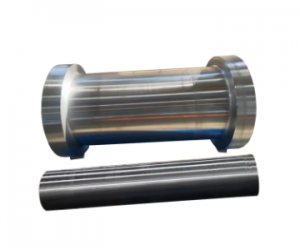

Tube Forging Hollow Bars

Khoom Paub meej:

Qhov chaw ntawm Keeb Kwm: Shanxi

Hom Lub Npe: DHDZ

Ntawv pov thawj: ASME, JIS, DIN, GB, GB, thiab, AS, ASTM A370, API 6B, API 6C

Daim Ntawv Qhia Kev Xeem: MTC, HT, HTT, Daim Ntawv Qhia Tawm, Kuaj, EN1020-3.1, EN1020-3.2

Specification: TUV / Bed 2014/68 / EU

Yam tsawg kawg nkaus txiav txim kom muaj nuj nqis: 1 daim

Pob Thauj: Cov Ntaub Ntawv Plywood

Nto Kho: Polishing

Nqe: Muaj Peev Xwm

Muaj Peev Xwm Ntau Lawm: 20000 TUJ / XYOO

| Khoom siv khoom | C | Mn | P | S | SI | Cr | NI | Mo | Cu | N |

| A182 F51 | ≤ 0.030 | 2.0 | ≤ 0.030 | ≤ 0.020 | <0.80 | 21-23 | 4.5-6.5 | 2.50-3.50 | / | 0.20-0.24 |

| A182 F53 | ≤ 0.030 | ≤ 1.20 | ≤ 0.035 | <0.020 | <0.80 | 24-26 | 6.0-8.0 | 3-5 | <0.50 | 0.24-0.32 |

| 34Crnimo6 | 0.3-0.38 | 0.5-0.8 | ≤ 0.025 | ≤ 0.035 | ≤ 0.4 | 1.3-1.7 | 1.3-1.7 | 0.15-0.3 | / | / |

| 16md | 0.13-0.20 | 1.2-1.6 | I≤0.030 | I≤0.030 | 0.17-0.37 | I≤0.30 | I≤0.30 | / | / | / |

| 20mnmo | 0.17-0.23 | 1.1-1.4 | I≤0.025 | I≤0.015 | 0.17-0.37 | I≤0.030 | I≤0.030 | 0.20-0.35 | / | / |

| 20mnono | 0.16-0.23 | 1.2-1.5 | I≤0.035 | I≤0.035 | 0.17-0.37 | / | / | 0.45-0.60 | / | 0.20-0.45 |

| Cov Cuab Yeej Cuab Yeej Cuab Yeej | Dia. (Hli) | TS / RM (MPA) | YS / RP0.2 (MPA) | EL / A5 (%) | Ra / z (%) | Nthuav tawm | Kev Cuam Tshuam Lub Zog | HBW |

| A182 F51 | / | ≥620 | ≥450 | ≥25 | > 45 | V | ≥45j | / |

| A182 F53 | / | ≥800 | ≥550 | ≥15 | / | V | / | <310 |

| 34Crnimo6 | Ф12.5 | ≥785 | / | ≥11 | ≥30 | V | ≥71j | / |

| 16md | Tus miv | 470-630 | ≥345 | ≥21 | / | V | / | / |

| 20mnmo | Tus miv | ≥605 | ≥475 | ≥25 | / | V | ≥180 | / |

| 20mnono | Tus miv | ≥635 | ≥490 | ≥15 | / | U | ≥47 | 187-229 |

Cov txheej txheem ntau lawm:

Forging Txheej Txheem Tswjhwm Zoo: Cov Khoom Siv Hluav Taws Xob Hluav Taws Xob) → Kev Ntsuas Kub (Lub Tshuab Cua Sov Khij (Steel Stamp, Mark) → Cia Thauj Khoom

Hom tau zoo:

Cov khoom siv tau zoo heev,

High-precision qhov ntev ntev kev ua siab ntev,

Tswj cov txheej txheem ntau lawm,

Tsim siab tsim khoom thiab tshuaj xyuas cov khoom siv,

Cov Txheej Txheem Zoo Txheej Txheem,

Tsim sib txawv raws li cov neeg yuav tsum tau ua,

Them sai sai ntawm pob tiv thaiv,

Kev pab qhia zoo puv.

Kev thov kev lag luam:

Cov khoom siv metallurgical, cov khoom siv mining, tua cov hlab ntsha, nqa khoom siv tshuab, siv tshuab, hluav taws xob, thiab lwm yam.