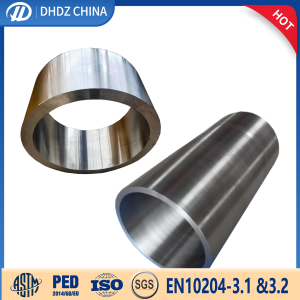

Alloy Steel Gear Ring

Khoom Paub meej:

Qhov chaw ntawm Keeb Kwm: Shanxi

Hom Lub Npe: DHDZ

Daim ntawv pov thawj: ASME, JIS, DIN, GB, BS, EN, AS, SABS, ASTM A370, API 6B, API 6C

Daim Ntawv Qhia Kev Xeem: MTC, HT, UT, MPT, Dimension Report, Visual Test, EN10204-3.1, EN10204-3.2

Yam tsawg kawg nkaus Order Quantity: 1 pcs

Thauj Pob: Plywood Case

Nqe: Negotiable

Muaj peev xwm ntau lawm: 100PCS / hli

| Khoom siv | C | Mn | P | S | SI | Cr | NI | Mo | Cu | N |

| 4 140 | 0.43 ib | 1.0 | <0.030 | <0.040 | <0.35 | 0.8-1.1 | <0.030 | 0.15-0.25 dr hab | <0.030 | / |

| F6Mn | ≤ 0.05 | 1.0 | ≤ 0.03 | ≤ 0.03 | ≤ 0.60 | 11-14 | 3.5-5.5 | 0.5-1 | / | / |

| 09G2S (09G2C) | ≤ 0.12 | 1.3-1.7 Nws | ≤ 0.03 | ≤ 0.035 | 0.5-0.8 hli | ≤ 0.3 | ≤ 0.3 | / | ≤ 0.3 | ≤ 0.008 |

| 35 NiCrMoV12-5 | 0.30-0.40 Nws | 0.4-0.7 hli | ≤ 0.015 | ≤ 0.015 | ≤ 0.35 | 1.0-1.4 tsi | 2.5-3.5 | 0.35-0.65 Nws | / | / |

| 20 MnMo | 0.17-0.23 dr hab | 1.1-1.4 ib | ≤ 0.025 | ≤ 0.015 | 0.17-0.37 Nws | ≤ 0.030 | ≤ 0.030 | 0.20-0.35 dr hab | / | / |

| 20 MnMoNo | 0.16-0.23 dr hab | 1.2-1.5 hli | ≤ 0.035 | ≤ 0.035 | 0.17-0.37 Nws | / | / | 0.45-0.60 Nws | / | 0.20-0.45 dr hab |

| Cov cuab yeej cuab tam | Dia.(mm) | TS/Rm (Mpa) | YS/Rp0.2 (Mpa) | EL / A5 (%) | RA/Z (%) | Ntsig | Kev cuam tshuam lub zog | HBW |

| 4 140 | Ф10 | *1080 | ua 930 | > 25 | 45 | V | ≥25J (-60 ℃) | <217 |

| F6Mn | / | ≥790 | ≥620 | ≥15 | ≥45 | V | / | ≤ 295 |

| 09G2S (09G2C) | Ф25 | 900-1050 Nws | ≥700 | ≥10 | ≥50 | V | / | / |

| 35 NiCrMoV12-5 | F12.5 | ≥1100 | ≥850 | ≥8.0 | / | V | / | / |

| 20 MnMo | Ф10 | ≥605 | ≥475 | ≥ 25 | / | V | ≥180 | / |

| 20 MnMoNo | Ф10 | ≥635 | ≥490 | ≥15 | / | U | ≥47 | 187-229 : kuv |

Cov txheej txheem tsim khoom:

Forging txheej txheem khiav zoo tswj: Raw khoom steel ingot rau hauv warehouse (kuaj cov tshuaj cov ntsiab lus) → Txiav → Cua sov (Lub cub tawg ntsuas kub) → Thaum tshav kub kub kev kho mob tom qab forging (Lub cub tawg ntsuas kub) Tshem tawm lub cub tawg (kev tshuaj ntsuam dawb paug) → Machining → Inspection (UT , MT, Visal diamention, hardness) → QT → Kev tshuaj xyuas (UT, mechanical zog, hardness, grain loj) → Finish machining → Kev tshuaj xyuas (qhov ntev) → Ntim thiab kos npe (steel stamp, mark) → Cia khoom xa tuaj

Qhov zoo:

Zoo heev mechanical zog,

High-precision dimensional kam rau ua,

Tswj cov txheej txheem tsim khoom nruj me ntsis,

Advanced tsim khoom thiab tshuaj xyuas cov cuab yeej,

Zoo heev technical personality,

Ua qhov sib txawv raws li cov neeg siv khoom xav tau,

Ua tib zoo saib ntawm pob kev tiv thaiv,

Kev pabcuam zoo.