Forged nplhaib

Qhib Tuag Forgings Chaw tsim tshuaj paus nyob rau hauv Suav teb

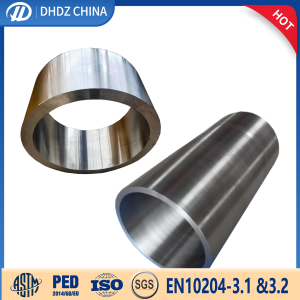

FORGED SEAMLESS ROLLED RINGS / FORGED RING / GEAR RING

Daim ntawv thov teb ntawm lub nplhaib forgings yog:

Diesel cav nplhaib forgings: ib hom diesel forgings, diesel cav diesel cav yog ib hom fais fab machinery, feem ntau yog siv los ua lub cav. Siv cov cav loj diesel ua piv txwv, cov forgings siv yog lub tog raj kheej taub hau, phau ntawv xov xwm tseem ceeb, crankshaft kawg flange tso zis kawg ncej, txuas pas nrig, piston pas nrig, piston taub hau, crosshead pin, crankshaft kis iav, nplhaib iav, nruab nrab iav thiab dye twj. Ntau tshaj kaum hom lub cev.

Marine nplhaib forgings: Marine forgings muab faib ua peb pawg, lub ntsiab forgings, ncej forgings thiab rudder forgings. Lub ntsiab chav tsev forgings yog tib yam li cov diesel forgings. Cov ncej forging muaj lub tog raj kheej, ib nrab ncej, thiab lwm yam. Forgings rau rudder systems muaj xws li rudder stock, rudder stock, thiab rudder pins.

Riam phom nplhaib forgings: Forgings tuav txoj haujlwm tseem ceeb hauv kev lag luam riam phom. Los ntawm qhov hnyav, 60% ntawm lub tank yog forged. Phom phom, muzzle retractor thiab stern nyob rau hauv artillery, rifled chim thiab daim duab peb sab bayonet nyob rau hauv infantry riam phom, sib sib zog nqus foob pob launcher thiab tsau lub rooj rau foob pob ua ntxaij thiab submarine, stainless steel valve lub cev rau nuclear submarine siab txias txias, plhaub, phom, thiab lwm yam., yog forged khoom. Ntxiv nrog rau cov hlau forgings, riam phom kuj yog tsim los ntawm lwm cov ntaub ntawv.

Petrochemical nplhaib forgings: Forgings muaj ntau yam kev siv hauv cov khoom siv petrochemical. Xws li manholes thiab flanges ntawm spherical cia tso tsheb hlau luam, ntau cov ntawv raj yuav tsum tau rau cov cua kub exchangers, forging cylinders (cov hlab ntsha siab) rau pob tw vuam flange catalytic cracking reactors, chim seem rau hydrogenation reactors, chiv rau saum lub hau, hauv qab cover, thiab lub taub hau yuav tsum tau rau cov khoom siv yog forgings.

Mine nplhaib forgings: Raws li qhov hnyav ntawm cov khoom siv, qhov feem ntawm forgings hauv cov khoom siv tsuas yog 12-24%. Cov cuab yeej siv mining muaj xws li: cov khoom siv mining, cov khoom siv hoisting, cov khoom siv crushing, cov khoom sib tsoo, cov cuab yeej ntxuav, thiab cov khoom siv sintering.

Nuclear fais fab ntiv nplhaib forgings: Nuclear fais fab tau muab faib ua ob hom: cov dej siab reactors thiab boiling dej reactors. Lub ntsiab loj forgings ntawm nuclear fais fab nroj tsuag tuaj yeem muab faib ua ob pawg loj: lub plhaub siab thiab cov khoom siv sab hauv. Lub plhaub siab muaj xws li: lub tog raj kheej flange, ntu nozzle, lub nozzle, lub tog raj kheej sab sauv, lub tog raj kheej qis, ntu hloov lub tog raj kheej, ntsia liaj qhov rooj, thiab lwm yam. Cov khoom siv sab hauv ntawm pawg yog ua haujlwm nyob rau hauv cov xwm txheej hnyav xws li kub siab, kub siab, muaj zog neutron irradiation, boric acid dej corrosion, scouring thiab hydraulic vibration, yog li 18-8 austenitic stainless hlau siv.

Thermal power ring forgings: Muaj plaub qhov tseem ceeb forgings hauv cov khoom siv hluav taws xob tsim hluav taws xob, uas yog lub rotor thiab tuav lub nplhaib ntawm lub tshuab hluav taws xob, thiab lub impeller thiab chav turbine rotor hauv chav turbine.

Hydroelectric nplhaib forgings: tseem ceeb forgings nyob rau hauv hydropower chaw nres tsheb khoom muaj xws li turbine shafts, hydro-generator shafts, daim iav daim hlau, thrust taub hau, thiab lwm yam.

Khoom siv: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 |42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30 NiCrMo12 | 22NiCrMoVEN 1.4201

FORGED RING

Loj forged nplhaib mus txog OD 5000mm x ID 4500x Thk 300mm seem. Forging nplhaib kam rau ua feem ntau -0 / + 3mm txog +10mm nyob ntawm qhov loj me.

Tag nrho cov hlau muaj lub peev xwm forging los tsim lub nplhaib forged los ntawm cov nram qab no alloy hom:

● Alloy hlau

● Carbon steel

● Stainless hlau

FORGED Nplhaib muaj peev xwm

Khoom siv

MAX DIAMETER

MAX WEIGHT

Carbon, hlau alloy

5000 hli

15 000 kgs

Stainless hlau

5000 hli

10000 kgs

Shanxi DongHuang Cua Fais Fab Flange Manufacturing Co., Ltd. , raws li ISO sau ntawv pov thawj forging chaw tsim tshuaj paus, lav tias cov forgings thiab / los yog tuav yog homogenous nyob rau hauv zoo thiab tsis muaj anomalies uas yog detrimental rau lub mechanical zog los yog machining properies ntawm cov khoom.

Case:

Qib Steel1.4201

Tshuaj muaj pes tsawg leeg % ntawm steel 1.4201

| C | Si | Mn | P | S | Cr |

| Min. 0.15 | - | - | - | - | 12.0 Nws |

| Max. - | 1 | 1 | 0.040 ib | 0.03 ib | 14.0 Nws |

| Qib | UNS No | qub British BS | Euronorm En | Swedish Tsis muaj npe | Japanese SS JIS | Suav GB/T 1220 |

| 420 | S42000 | 420s37 ib | 56C 1.4021 X20Cr13 | 2303 ib | SUS 420J1 | 2 cr13 |

Cov hlau qib 1.4021 (tseem hu ua ASTM 420 thiab SS2303) yog lub zog tensile siab martensitic stainless hlau nrog cov khoom zoo corrosion. Cov hlau yog machinable thiab suits zoo rau kev tsim cov ntsiab lus nrog kev ua haujlwm zoo xws li huab cua chav dej, dej tshiab, qee cov tshuaj alkaline thiab lwm yam tshuaj lom neeg hnyav. Nws yuav tsum tsis txhob siv rau hauv marine lossis hauv ib puag ncig chloride. Cov hlau yog sib nqus thiab nyob rau hauv quenched thiab tempered mob.

Daim ntawv thov

Qee qhov chaw thov rau EN 1.4021

Twj- thiab Valve qhov chaw, Shafting, Spindels, Piston rods, Fittings, Stirrers, Bolts, Ceev EN 1.4021 Forged nplhaib, Stainless hlau forgings rau Slewing nplhaib.

Loj: φ840 x φ690x H405mm

Forging (kub ua hauj lwm) xyaum, kev kho cua sov txheej txheem

| Annealing | 800-900 ℃ |

| Tempering | 600-750 ℃ |

| Quenching | 920-980 ℃ |

| Rm- Tensile zog (MPa) (A) | 727 ib |

| rp0.2 ua0.2% pov thawj lub zog (MPa) (A) | 526 ib |

| A- Min. elongation ntawm tawg (%) (A) | 26 |

| Z - Kev txo qis hauv ntu ntu ntawm pob txha (%) (A) | 26 |

| Brinell hardness (HBW): (+A) | 200 |

Cov ntaub ntawv ntxiv

THOV QHIA NTAU HNUB NO

LOSSIS Hu rau: 86-21-52859349