ʻO nā mea e kalaʻole ana

Nā kiko'ī huahana:

Wahi o ka kumu: shanxi

Inoa inoa: dhdz

Kaho: Asme, Jis, Dis, Dis, BS, BS, en, he ao Sab, Ap. API 6b, API 6b

Hōʻike hōʻike: MTC, HTC, UT, MPT, DEMSION hōʻike, EN10204-3.1, en10204-3.2

Specfififification: tuv / ped 2014/68 / EU

Ka helu helu helu liʻiliʻi: 1'āpana

Ke kāleleʻana i ka pākeke: Plywood Case

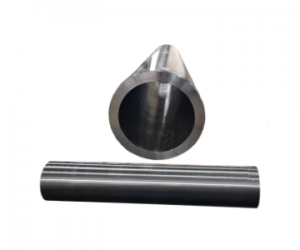

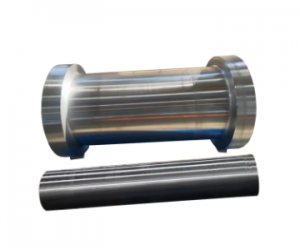

Hana kino: polishing

Kumukūʻai: Kūkākūkā

KA MANA: 20000 TON / makahiki

| Nā Kūlana Mokuna | C | Mn | P | S | SI | Cr | NI | Mo | Cu | N |

| A182 F51 | ≤ wallaka | 2.0 | ≤ wallaka | ≤ 0.020 | <0.80 | 21-23 | 4.5-6.5 | 2.50-3.50 | / | 0.20-0.24 |

| A182 F53 | ≤ wallaka | ≤ 1.20 | Ер 0135 | 3. 0.020 | <0.80 | 24-26 | 6.0-8.0 | 3-5 | <0.50 | 0.24-0.32 |

| 34crnimo6 | 0.3-0.38 | 0.5-0.8 | ≤ 0.022 | Ер 0135 | ≤ 0.4 | 1.3-1.7 | 1.3-1.7 | 0.15-0.3 | / | / |

| 16 KaHani | 0.13-0.20 | 1.2-1.6 | ≤ >.030 | ≤ >.030 | 0.17-0.37 | Ç0.30 | Ç0.30 | / | / | / |

| 20mnmo | 0.17-0.23 | 1.1-1.4 | ≤ ».0.025 | Ç0.015 | 0.17-0.37 | ≤ >.030 | ≤ >.030 | 0.20-0.35 | / | / |

| 20mnhoun | 0.16-0.23 | 1.2-1.5 | Ç ».035 | Ç ».035 | 0.17-0.37 | / | / | 0.45-0.60 | / | 0.20-0.45 |

| Waiwai waiwai | Dia. (Mm) | Ts / RM (MPA) | YS / RP0.2 (MPA) | El / A5 (%) | RA / Z (%) | Notch | Ka hopena hopena | Hbw |

| A182 F51 | / | ≥620 | ≥450 | ≥25 | > 45 | V | ≥45j | / |

| A182 F53 | / | ≥800 | ≥550 | ≥15 | / | V | / | <310 |

| 34crnimo6 | Фо_.5 | ≥785 | / | ≥11 | ≥30 | V | ≥11j | / |

| 16 KaHani | ФФ10 | 470-630 | ≥345 | ≥21 | / | V | / | / |

| 20mnmo | ФФ10 | ≥605 | ≥475 | ≥25 | / | V | ≥180 | / |

| 20mnhoun | ФФ10 | ≥635 | ≥490 | ≥15 | / | U | ≥47 | 187-229 |

Nā kaʻina hana.

Ke kalaʻana i ke kaʻina hana o ke kaheʻana o ke kaheʻana: E nānā i nā mea kūʻai aku ma ke kaʻina hana). Nānā (dimension) → packing a me ka hōʻailonaʻana (steel stamp, hōʻailona)

Pono:

Nā mea hana ponoʻole,

ʻO ka piʻiʻana o ka piʻi kiʻekiʻe

Kāohi i ke kaʻina hana hana paʻa,

Nā Mea Hana Hana Hana Hana Hana HanaʻO nā Hana Hana,

ʻO keʻano pilikino maikaʻi loa,

E hana i nā dimensionʻokoʻa e pili ana i nā koi o ka mea kūʻai aku,

E mālama pono i ka pale pale.

Ka lawelawe piha piha.

Nāʻoihana noi:

Nā Hana Aimu, Nā Hana Mining aku, Nā Hana Lakepili, Paʻa Hana, E ke ahi'āina, Nā faion.s.