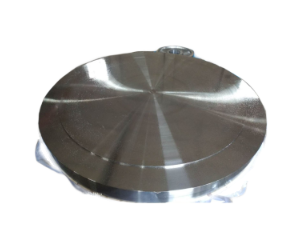

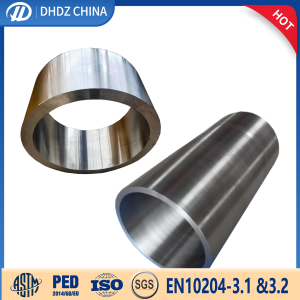

Nā Kiʻi Paʻa kila

Nā kikoʻī huahana:

Kahi i kumu: Shanxi

Kapa inoa: DHDZ

Nā palapala hōʻoia: TUV/ PED 2014/68/EU

Hōʻike hoʻāʻo: En10204-3.1, MTC, EN10204-3.2

Ka hoʻomanawanui ʻana: +/-0.5mm

Ka nui o ke kauoha liʻiliʻi: 1 ʻāpana

Puke Kaʻa: Plywood Case/Brandrith

Kumukūʻai:Negotiable

Hana Hana: 2000 Ton / Makahiki

| Nā mea waiwai | C | Mn | P | S | SI | Cr | NI | Mo | Cu | N |

| 4130 | 0.33 | 0.7 | <0.025 | <0.025 | <0.35 | 0.8-1.0 | <0.5 | 0.15-0.25 | / | / |

| A182 F53 | ≤ 0.030 | ≤ 1.20 | ≤ 0.035 | <0.020 | <0.80 | 24-26 | 6.0-8.0 | 3-5 | <0.50 | 0.24-0.32 |

| F6Mn | ≤ 0.05 | 1.0 | ≤ 0.03 | ≤0.03 | ≤0.60 | 11-14 | 3.5-5.5 | 0.5-1 | / | / |

| C45 | 0.42-0.50 | 0.5-0.8 | ≤ 0.035 | ≤ 0.035 | 0.17-0.37 | ≤ 0.25 | <0.5 | / | ≤ 0.30 | / |

| 35NiCrMoV12-5 | 0.30-0.40 | 0.4-0.7 | ≤ 0.015 | ≤ 0.015 | ≤ 0.35 | 1.0-1.4 | 2.5-3.5 | 0.35-0.65 | / | / |

| 20MnMoNo | 0.16-0.23 | 1.2-1.5 | ≤0.035 | ≤0.035 | 0.17-0.37 | / | / | 0.45-0.60 | / | 0.20-0.45 |

| Waiwai mīkini | Dia.(mm) | TS/Rm (Mpa) | YS/Rp0.2 (Mpa) | EL/A5 (%) | RA/Z (%) | Notch | Ka ikehu hopena | HBW |

| 4130 | Ф10 | >655 | >517 | >18 | >35 | V | ≥20J(-60 ℃) | 197-23 |

| A182 F53 | / | ≥800 | ≥550 | ≥15 | / | V | / | <310 |

| F6Mn | / | ≥790 | ≥620 | ≥15 | ≥45 | V | / | ≤295 |

| C45 | Ф12.5 | ≥540 | ≥240 | ≥16 | / | V | / | / |

| 35NiCrMoV12-5 | Ф12.5 | ≥1100 | ≥850 | ≥8.0 | / | V | / | / |

| 20MnMoNo | Ф10 | ≥635 | ≥490 | ≥15 | / | U | ≥47 | 187-229 |

Nā Kaʻina Hana Hana:

Ka hoʻomalu ʻana i ka maikaʻi o ka holo ʻana o ke kaʻina hana: ʻO nā mea kila i loko o ka hale kūʻai (e hoʻāʻo i ka ʻike kemika) → ʻoki → Hoʻomaʻamaʻa (Hoʻāʻo wela o ka umu) → Hoʻomaʻamaʻa wela ma hope o ka hana ʻana (Hoʻāʻo wela i ka umu) ,MT, Visal diamention, hardness)→ QT→ Inspection(UT, mechanical properties, hardness, grain size)→ Finish machining → Nānā (dimension) → Hoʻopili a me ka hōʻailona ʻana (steel stamp, mark)→ Storage Ship

Pōmaikaʻi:

ʻO nā waiwai mechanical maikaʻi loa,

ʻO ka hoʻomanawanui ʻana o ke ana kiʻekiʻe,

E mālama pono i ke kaʻina hana,

ʻO nā lako hana kiʻekiʻe a me nā mea nānā,

ʻO ke kanaka ʻenehana maikaʻi loa,

E hana i nā ʻano like ʻole e pili ana i nā koi o ka mea kūʻai aku,

E noʻonoʻo i ka pale ʻana i ka pūʻolo,

ʻO ka lawelawe piha maikaʻi.

Nā ʻoihana noi:

ʻO ka ʻoihana hana meaʻai, ka hana ʻana i nā lako, ka lako wai a me ka hoʻoheheʻe ʻana, ka ʻoihana hana moku, etc.