ʻO ka hōʻea hou ʻana ʻo Kina Forgings Steel Orifice Flanges – Forged Tubes – DHDZ

ʻO ka hōʻea hou ʻana o Kina Forgings Steel Orifice Flanges – Forged Tubes – DHDZ Detail:

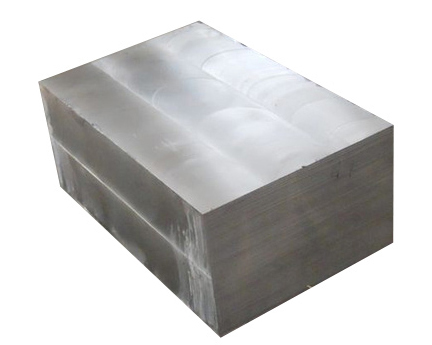

Open Die ForgingsMea Hana Ma Kina

PALAPALA PALAPALA/ PALAPALA PALAPALA

| Max. OD | Max. Ka lōʻihi | Max. Kaumaha |

| 1000mm | 3000mm | 12 000 Kgs |

Hoʻokumu ʻo DHDZ i ka hoʻopaʻa ʻole ʻia, paʻa paʻa kaumaha a me nā lima lima i nā ʻano hoʻonohonoho maʻamau e like me nā koi o ka mea kūʻai aku. He mea kūpono nā hollows forged seamless no nā noi koʻikoʻi kiʻekiʻe a me nā kaiapuni paʻakikī ma muli o ko lākou lōʻihi, ikaika a me ka pale ʻana i ka corrosion. ʻAʻole hiki ke hana ʻia nā Hollows ma ke ʻano cylindrical pololei, akā me nā ʻano like ʻole o nā OD a me nā ID, me nā tapers.

Eia kekahi, hāʻawi ʻo DHDZ i nā hana hoʻoheheʻe a pau e pili ana i ka mālama wela, ka mīkini a me ka hoʻāʻo ʻana i ka mīkini a me ka hoʻāʻo ʻole, ma ke noi. E hoʻokaʻaʻike mai iā mākou i kēia lā me kāu mau kikoʻī kikoʻī, e hana pū kā mākou hui me ʻoe e hoʻonui i kā mākou hiki ke hōʻemi i ka ʻōpala waiwai a hōʻemi i nā hemahema o ke kaʻina hana.

Mea hoʻohana maʻamau: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 | 42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30NiCrMo12 |22NiCrMoV |EN 1.4201 |42CrMo4

ʻO Shanxi DongHuang Wind Power Flange Manufacturing Co., LTD., ma ke ʻano he ISO i hoʻopaʻa inoa ʻia i ka mea hana forging, e hōʻoiaʻiʻo i ka like ʻole o nā forgings a / a i ʻole nā pa i ka maikaʻi a me ka ʻole o nā anomalies e hōʻino ʻia i nā waiwai mechanical a i ʻole nā machining properies o ka mea.

Hōʻike huahana

ʻO mākou kekahi mea hana nui o AISI 4140, SAE 4140 Forged / forging pipes, AISI 4140, SAE 4140 Forged / forging tubes, AISI 4140, SAE 4140 Forged / forging hollow bars, 42Crmo4 Forged / forging pipes, 42Crmo4 Forged / forging pipes, 42Crmo4 Forged/4Crmo4 pipes Paʻa/paʻi ʻia i nā ʻaukā, 1.7225 Paʻa/paʻa paipu, 1.7225 Paʻa/paʻi ʻia nā paipu, 1.7225 Paʻa/paʻa ʻana i nā kīʻaha kīwī mai Kina.

Hiki iā mākou ke hana i ka AISI 4140, SAE 4140 Forged/forging pipes, AISI 4140, SAE 4140 Forged/forging tubes, AISI 4140, SAE 4140 Forged/forging hollow bars, 42Crmo4 Forged/forging pipes, 42Crmo4 Forging tubes/forging tubes. nā kī kī, 1.7225 Paipu Forged/forging, 1.7225 Forged/forging tubes, 1.7225 Forged/forging hollow bars me nā anawaena mai 100MM a 1200MM, me ka lenth mai 100MM a 10000MM, ke kaumaha mai 150KGS a 10KGS.

Hiki iā mākou ke hana i ka mīkini ʻawaʻawa a i ʻole ka mīkini hope loa o AISI 4140, SAE 4140 Paipu Forged/forging pipe, AISI 4140, SAE 4140 Forged/forging tubes, AISI 4140, SAE 4140 Forged/forging hollow bars, 42Crmo4 Forged/forging tubes, 42Crmo4 Forged/forging tubes 42Crmo4 Paʻa/paʻi ʻana i nā kaola ʻāwaha, 1.7225 Paʻa/paʻa ʻia nā paipu, 1.7225 Paʻi ʻia/paʻi ʻana i nā paipu, 1.7225 Paʻi ʻia/kala ʻana i nā ʻauheʻe e like me ke kaha kiʻi a nā mea kūʻai aku.

Hana wela:Hoʻopili maʻamau / Annealed / Quenched / hoʻonā

Lapaʻau ʻili:pena, hoʻopalapala, hoʻopololei, ʻekeʻeleʻele, ʻaila anti-rust mālohi

Mana maikaʻi:UT, MT, RT, PT, ho'āʻo haku mele, hoʻāʻo waiwai mechanical, etc.

Nānā

1. Palapala hōʻoia waiwai (mea hana kemika)

2. Heat lapaau pepa hoike

3. Hōʻike nānā ana

4. Hōʻike hoʻāʻo UT

Kūlana hoʻouna

Wela hoʻoheheʻe ʻia + Rough machined (ʻeleʻele ma hope o Q /T)+ Huli

Pōmaikaʻi hoʻokūkū

ʻO ka mana maikaʻi a me ka hoʻokele ʻana i ke kaʻina hana holoʻokoʻa, me ka hoʻoheheʻe ʻana i ka ingot, forging, mālama wela, mīkini a me ka nānā hope loa ma mua o ka lawe ʻana.

ʻOi aku ka maikaʻi o ka huahana a me ka lawelawe, ke kumukūʻai hoʻokūkū, "i ka manawa" hāʻawi

hihia:Ke kila kila AISI 4140 Alloy Steel

Na Waiwai Kino

| Waiwai | Metric | Mperial |

| ʻO ka mānoanoa | 7.85 g/cm3 | 0.284 paona/in³ |

| Lae hehee | 1432°C | 2610°F |

ʻO AISI 4140 Alloy Steel Nā kikoʻī pili a me nā mea like

| AISI 4130 | C | Mn | Si | P | S | Cr | Mo | Ni | Cu | Mo |

| 0.38 – 0.43 | 0.75 – 1.00 | 0.15 – 0.35 | 0.030 ka nui | 0.040 ka nui | 0.80-1.10 | 0.15-0.25 |

0.25 max | 0.35 max | 0.15-0.25 |

| ASTM A29/A29M | DIN17350 | BS 970 | JIS G4105 | GB/T 3077 | AS 1444 | ISO 683/18 |

| AISI 4140 | 1.7225/ | 42CrMo4 | SCM440 | 42CrMo | 4140 | 25CrMo4 |

| 42CrMo4 |

Hoʻomaʻamaʻa Forging (Hot Work) , Heat Treatment Proc

| Ke kalaiwa ana | 1093-1205 ℃ |

| Hoʻopili | 778-843 ℃ ka umu wela |

| ʻO ka hoʻohenehene | 399-649 ℃ |

| Hoʻoponopono maʻamau | 871-898 ℃ ea anuanu |

| Austenize | 815-843 ℃ kinai wai |

| Hoʻopau pilikia | 552-663 ℃ |

| Ke kinai ana | 552-663 ℃ |

| Rm - Ka ikaika uʻi (MPa) (Q +T) | ≥930 |

| Rp0.2 0.2% ikaika hōʻoia (MPa) (Q +T) | ≥785 |

| KV - Ka ikehu hopena (J) (Q +T) | +20° ? |

| A - Min. elongation ma ka haʻihaʻi (%)(Q +T) | ≥12 |

| Z - Hoemi i ka pauku kea ma ka haki (%)(N+Q +T) | ≥50 |

| ʻO Brinell paakiki (HBW): (Q +T) | ≤229HB |

OLELO HOIKE

NOI I KA PALAPALA I KEIA LA

A I OLE KELE: 86-21-52859349

Nā kiʻi kikoʻī huahana:

Alakaʻi Huahana Pili:

Ke koi nei kā mākou ʻoihana i ke kulekele maʻamau o "ʻo ka huahana kiʻekiʻe ke kumu o ke ola ʻoihana; ʻo ka ʻoluʻolu o ka mea kūʻai aku hiki ke lilo i ka maka a me ka hoʻopau ʻana i kahi ʻoihana; ʻo ka hoʻomaikaʻi mau ʻana ʻo ia ka ʻimi mau ʻana o nā limahana" a me ke kumu kūlike o "ka inoa mua, ka mea kūʻai mua" no ka New Arrival China Forgings Steel Orifice Flanges – Forged Tubes – DHDZ , ʻO ka huahana e hāʻawi aku i nā wahi a pau. Hāʻawi mākou i ka lawelawe akamai, pane wikiwiki, hāʻawi manawa kūpono, maikaʻi maikaʻi a me ke kumukūʻai maikaʻi loa i kā mākou mea kūʻai. ʻO ka ʻoluʻolu a me ka hōʻaiʻē maikaʻi i kēlā me kēia mea kūʻai aku kā mākou mea nui. Kūleʻa mākou i kēlā me kēia kikoʻī o ka hoʻoponopono kauoha no nā mea kūʻai aku a hiki i ka loaʻa ʻana o nā mea palekana a maikaʻi me ka lawelawe logistics maikaʻi a me ke kumukūʻai waiwai. Ma muli o kēia, kūʻai maikaʻi ʻia kā mākou huahana a me nā hoʻonā i nā ʻāina ma ʻApelika, ka Mid-East a me Asia Hema. ʻO ka pili ʻana i ka manaʻo ʻoihana o ka mea kūʻai mua, e hoʻomau i mua', mahalo mākou i nā mea kūʻai mai ma ka home a ma waho e hui pū me mākou.

Ma keʻano laulā, ua māʻona mākou i nā ʻano āpau, ʻuʻuku, kiʻekiʻe, hoʻopuka wikiwiki a me ke ʻano procuct maikaʻi, e loaʻa iā mākou ka launa pū ʻana!