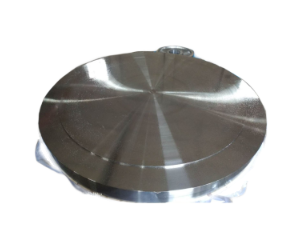

Steel Forged Discs

Iinkcukacha zeMveliso:

Indawo yemvelaphi: Shanxi

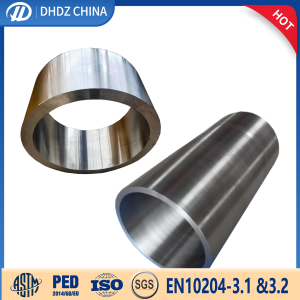

Igama leBrand: DHDZ

Iziqinisekiso: TUV/PED 2014/68/EU

Ingxelo yoVavanyo: En10204-3.1, MTC, EN10204-3.2

Ukunyamezela ukunyamezela: +/-0.5mm

Ubuncinci boMyalelo ubungakanani: isiqwenga esi-1

Ipakethe yezoThutho: I-Plywood Case/Brandrith

Xabiso:Kuyancokolwa

Umthamo weMveliso: 2000 Ton/Unyaka

| Izinto eziphathekayo | C | Mn | P | S | SI | Cr | NI | Mo | Cu | N |

| 4130 | 0.33 | 0.7 | <0.025 | <0.025 | <0.35 | 0.8-1.0 | <0.5 | 0.15-0.25 | / | / |

| A182 F53 | ≤ 0.030 | ≤ 1.20 | ≤ 0.035 | <0.020 | <0.80 | 24-26 | 6.0-8.0 | 3-5 | <0.50 | 0.24-0.32 |

| F6Mn | ≤ 0.05 | 1.0 | ≤ 0.03 | ≤0.03 | ≤0.60 | 11-14 | 3.5-5.5 | 0.5-1 | / | / |

| C45 | 0.42-0.50 | 0.5-0.8 | ≤ 0.035 | ≤ 0.035 | 0.17-0.37 | ≤ 0.25 | <0.5 | / | ≤ 0.30 | / |

| 35NiCrMoV12-5 | 0.30-0.40 | 0.4-0.7 | ≤ 0.015 | ≤ 0.015 | ≤ 0.35 | 1.0-1.4 | 2.5-3.5 | 0.35-0.65 | / | / |

| 20MnMoNo | 0.16-0.23 | 1.2-1.5 | ≤0.035 | ≤0.035 | 0.17-0.37 | / | / | 0.45-0.60 | / | 0.20-0.45 |

| Ipropathi yoomatshini | Dia.(mm) | TS/Rm (Mpa) | YS/Rp0.2 (Mpa) | EL/A5 (%) | RA/Z (%) | Inotshi | Amandla empembelelo | HBW |

| 4130 | Ф10 | 655 | >517 | >18 | >35 | V | ≥20J(-60℃) | 197-23 |

| A182 F53 | / | ≥800 | ≥550 | ≥15 | / | V | / | <310 |

| F6Mn | / | ≥790 | ≥620 | ≥15 | ≥45 | V | / | ≤295 |

| C45 | Ф12.5 | ≥540 | ≥240 | ≥16 | / | V | / | / |

| 35NiCrMoV12-5 | Ф12.5 | ≥1100 | ≥850 | ≥8.0 | / | V | / | / |

| 20MnMoNo | Ф10 | ≥635 | ≥490 | ≥15 | / | U | ≥47 | 187-229 |

Iinkqubo zeMveliso:

Inkqubo yokuqulunqa ulawulo lomgangatho wokuhamba: Intsimbi yentsimbi ekrwada kwindawo yokugcina (vavanya umxholo wekhemikhali) → Ukusika→ Ukufudumeza(Uvavanyo lobushushu besithando somlilo) → Unyango lobushushu emva kokubunjwa(uvavanyo lobushushu besithando somlilo) Khupha isithando somlilo(uhlolo olungenanto)→Machining→ Ukuhlola(UT ,MT,iVisal diamention, ubulukhuni)→ QT→ Uhlolo(UT, iimpawu zomatshini, ubulukhuni, ubungakanani beenkozo)→ Gqiba machining→ Uhlolo (ubukhulu)→Ukupakisha nokuMakisha(isitampu sentsimbi, phawula)→Ukuthunyelwa kwempahla yokugcina

I-advanteji:

Iimpawu ezigqwesileyo zoomatshini,

Ukuchaneka okuphezulu komgangatho wokunyamezela,

Lawula inkqubo yokuvelisa ngokungqongqo,

Izixhobo zokuvelisa ezikumgangatho ophezulu kunye nezixhobo zokuhlola,

Ubuntu obugqwesileyo bobugcisa,

Ukuvelisa ubungakanani obahlukeneyo ngokusekelwe kwiimfuno zabathengi,

Nika ingqalelo kukhuseleko lwephakheji,

Inkonzo epheleleyo esemgangathweni.

Amashishini ezicelo:

Ishishini lokulungisa ukutya, ukwenziwa kwezixhobo, unikezelo lwamanzi kunye nokuhanjiswa kwamanzi, ukwakhiwa kweenqanawa, njl.