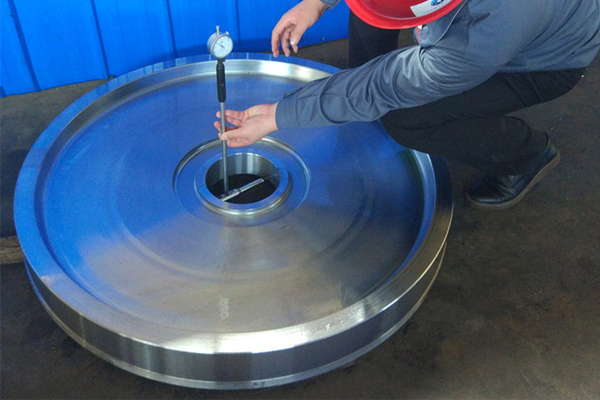

Ukuhlolwa komgangatho wembonakalo ngokuqhelekileyo kukuhlolwa okungonakalisi, ngokuqhelekileyo ngeso lenyama okanye ukuhlolwa kweglasi ekhulisayo ephantsi, ukuba kuyimfuneko, sebenzisa indlela yokuhlola engonakalisi.

Iindlela zokuhlola umgangatho wangaphakathi weforgings ezinzimainokushwankathelwa njengoku: ukuhlolwa kwentlangano ye-macroscopic, ukuhlolwa kwentlangano ye-microscopic, ukuhlolwa kwezakhiwo zoomatshini, uhlalutyo lwemichiza kunye novavanyo olungonakalisi.

Uvavanyo lweMicroscopic microstructure luhlobo lovavanyo lokujonga kunye nokuhlalutya iimpawu zemicrostructure yamandla aphantsiukwenzangeglasi yokukhulisa amandla abonakalayo okanye aphantsi. Iindlela ezisetyenziswa ngokuqhelekileyo zokuhlolwa kwesakhiwo semacroscopic yeforgingsyindlela yokuhlisa amandla asezantsi (kubandakanywa ukuthotywa kwe-thermal, i-cold corrosion kunye ne-electrolytic corrosion method), uvavanyo lwe-fracture kunye nendlela yokushicilela isulfure.

Umgaqo wokuhlolwa kweMicrostructure kukusebenzisa i-microscope yokukhanya ukujonga i-microstructure yeforgingszezinto ezahlukeneyo. Izinto zokuhlola ngokubanzi ziquka ubungakanani benkozo yangaphakathi, okanye ubungakanani beenkozo kwiqondo lokushisa elichaziweyo, okt ubungakanani bengqolowa obuyinyani, ukubandakanywa okungeyiyo okwentsimbi, i-microstructure efana ne-decarburization layer, i-eutectic carbide inhomogeneity, overheat, overburn kunye nezinye i-microstructure efunekayo, njl.

Iipropati zoomatshini kunye nokuhlolwa kokusebenza kwenkqubo kukuba ibe lunyango lokugqibela lobushushuforgingskunye neziqwenga zovavanyo zicutshungulwe kwisampulu echaziweyo emva kokusetyenziswa komatshini wokuvavanya i-tensile, umatshini wokuvavanya impembelelo, umatshini wokuvavanya ukunyamezela, umatshini wokuvavanya ukukhathala, umvavanyi wobulukhuni kunye nezinye izixhobo zokumisela iipropati zoomatshini kunye nexabiso lenkqubo yokusebenza.

Uvavanyo lokwakheka kweekhemikhali ngokuqhelekileyo kukusetyenziswa kohlalutyo lweekhemikhali okanye uhlalutyo olubonakalayo lohlalutyo lwamacandelo kunye novavanyo, kunye nophuhliso lwesayensi kunye nethekhnoloji, zombini uhlalutyo lweekhemikhali kunye nohlalutyo lwe-spectral lohlalutyo lwayo lwenze inkqubela phambili. Uhlalutyo lwe-spectral, ngoku alusebenzisi nje indlela ye-spectral kunye nendlela ye-spectroscopic yokwenza uhlalutyo lwecandelo, ukuvela kwe-photoelectric spectrometer kungekuphela nje uhlalutyo olukhawulezayo, kodwa nokuphucula kakhulu ukuchaneka, kunye nokuvela kwe-plasma photoelectric spectrometer kuye kwaphucula kakhulu ukuchaneka kohlalutyo, ukuchaneka kohlalutyo lwayo kunokufikelela kwinqanaba le-10, uhlalutyo olusebenzayo lunokufikelela kwinqanaba le-10. Pb, As, Sn, Sb, Bi in superalloy forgings.

Kutshiwo apha ngasentla, indlela yovavanyo, umbutho omkhulu, kunye nokwakhiwa kunye novavanyo lwe-microstructure okanye indlela yokusebenza okanye indlela, zonke zezendlela yokuvavanya eyonakalisayo, ngenxa yokuba ezinye iindlela ezinzima zeendlela ezitshabalalisayo azikwazi ukuziqhelanisa ngokupheleleyo nemfuno yokuhlola umgangatho, kwelinye icala, oku kungenxa yokuba ayilulo uqoqosho, kwelinye icala ubukhulu becala kukuphepha icala elinye lovavanyo olutshabalalisayo. Uphuhliso lwetekhnoloji ye-NDT ibonelela ngeendlela eziphucukileyo nezigqibeleleyoukwenzaukuhlolwa komgangatho.

Iindlela zovavanyo ezingonakalisiyo zokuhlola umgangatho ziqhelekile: indlela yokuhlola umgubo wemagnethi, indlela yokuhlola ukungena, indlela yokuhlola i-eddy yangoku, indlela yokuhlola i-ultrasonic.

Indlela yokuhlola amasuntswana emagnethi isetyenziswa ngokubanzi ukuhlola umphezulu okanye kufutshane neziphene zomhlaba zentsimbi yeferromagnetic okanye ialloy.forgings, ezifana nokuqhekeka, imibimbi, amabala amhlophe, inclusions non-metallic, delamination, ukusonga, carbide okanye bands ferritic, njl Le ndlela ilungele kuphela ukuhlolwa ferromagnetic.forgings, kodwa kungekhona ukubunjwa okwenziwe ngentsimbi ye-austenitic.

Indlela yokuhlola engeneyo ayinakujongisisa kuphela ukubunjwa kwemathiriyeli yemagnethi, kodwa ikwajonga iziphene ezikumphezulu zezinto ezingezizo iferromagnetic.forgings, njengokuqhekeka, ukukhululeka, ukugoqa, njl. Ngokuqhelekileyo, isetyenziselwa ukujonga iziphene ezingaphezulu kwe-non-ferromagnetic material forgings, kwaye ayikwazi ukufumana iziphene ezifihliweyo ngaphantsi komphezulu. Uvavanyo lwangoku lwe-Eddy lusetyenziselwa ukujonga umphezulu okanye kufutshane neziphene zomphezulu zezinto zokuqhuba.

Indlela yokuhlola i-ultrasonic isetyenziselwa ukukhangela iziphene zangaphakathi ze-forgings ezifana ne-shrinkage cavity, indawo emhlophe, i-core crack, ukufakwa kwe-slag, njl.

Ixesha lokuposa: Nov-17-2021