Iibha zoMgangatho

Vula uMvelisi weDie Forgings eTshayina

Iibha zoMgangatho

Izinto eziqhelekileyo ezisetyenziswayo: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 |42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30NiCrMo12 |22NiCrMoV12

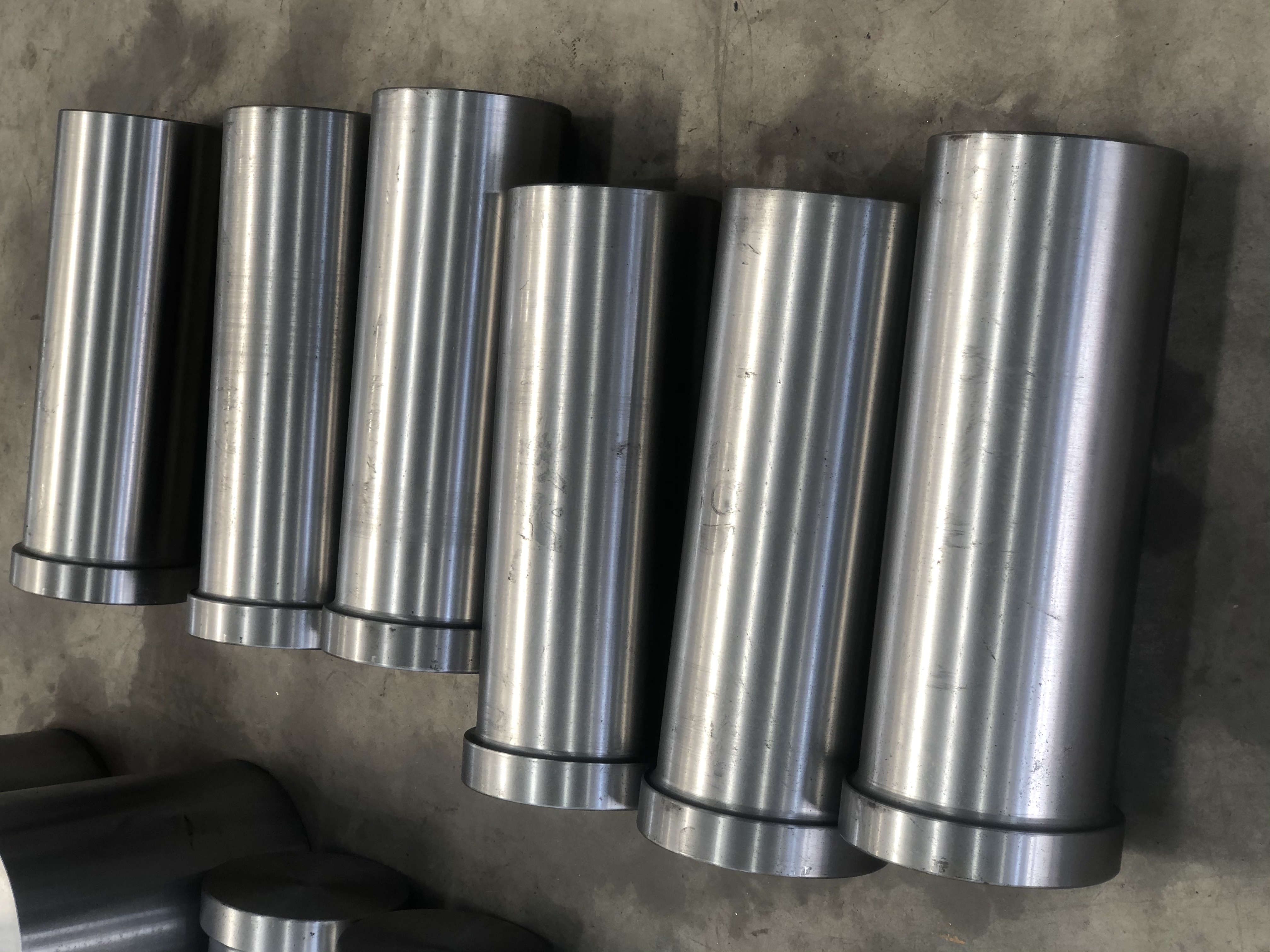

IIMILO ZEBHA EZENZIWEYO

Imivalo engqukuva, imivalo yesikwere, imivalo eyiFlethi kunye nemivalo yeHex. Zonke iiMetals zinamandla okubumba ukuvelisa imivalo kwezi ntlobo zealloyi zilandelayo:

● Intsimbi yentsimbi

● Intsimbi yekhabhoni

● Intsimbi engatyiwayo

IMISEBENZI YEBHA EYENZIWEYO

I-ALLOY

MAX UBUNZI

MAX WIGHT

Ikhabhoni, iAloyi

1500mm

26000 kgs

Yenziwe ngentsimbi eshayinayo

800mm

20000 kgs

IMISEBENZI YEBHA EYENZIWEYO

Obona bude buphezulu kwiibhari ezingqukuva ezibunjiweyo kunye neehex bars yi-5000 mm, kunye nobunzima obukhulu be-20000 kgs.

Ubude obuninzi kunye nobubanzi beebhari ezisicaba kunye nemivalo yesikwere yi-1500mm, kunye nobunzima obukhulu be-26000 kgs.

A ibha yenkohliso okanye ibha esongiweyoiveliswa ngokuthatha ingot kunyeukwenzaukuhla ukuya kubukhulu, ngokubanzi, iiflethi ezimbini ezichaseneyo ziyafa. Iintsimbi ezibunjiweyo zikholisa ukuba namandla, ziqine kwaye zomelele ngakumbi kuneefom ezityhidiweyo okanye iindawo ezenziwe ngoomatshini. Unokufumana ulwakhiwo lwengqolowa esetyenzisiweyo kuwo onke amacandelo e-forgings, ukwandisa amandla okumelana nokulwa kunye nokunxiba.

I-Shanxi DongHuang Wind Power Flange Manufacturing Co., LTD., Njengomvelisi obhalisiweyo we-ISO obhalisiweyo, isiqinisekiso sokuba i-forgings kunye / okanye imivalo i-homogenous kumgangatho kwaye ayinayo i-anomalies eyingozi kwiipropati ze-mechanical okanye i-machining properties.

Ityala:

IBanga leNsimbiEN 1.4923 X22CrMoV12-1

UlwakhiwoIMartensitic

| Ukwakhiwa kweekhemikhali % yentsimbi X22CrMoV12-1 (1.4923): EN 10302-2008 | ||||||||

| C | Si | Mn | Ni | P | S | Cr | Mo | V |

| 0.18 - 0.24 | ubuninzi 0.5 | 0.4 - 0.9 | 0.3 - 0.8 | ubuninzi 0.025 | ubuninzi 0.015 | 11 - 12.5 | 0.8 - 1.2 | 0.25 - 0.35 |

Usetyenziso

Iplanti yombane, ubunjineli boomatshini, ukwenziwa koMbane.

Izixhobo zemibhobho-imibhobho, iibhoyili ze-steam kunye nee-turbines.

Ifomu yokuhanjiswa

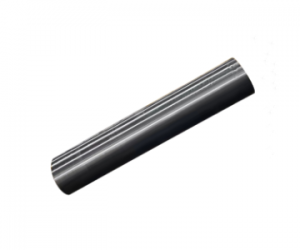

Ibar engqukuva, iiRings eziQoqiweyo zokubunjwa, iirawu eziBored, X22CrMoV12-1 Ibha yenzelwe

Ubungakanani: φ58x 536L mm.

Ukuqulunqa (umsebenzi oshushu) Ukuziqhelanisa

Izinto eziphathekayo zilayishwa kwisithando somlilo kwaye zishushu. Xa iqondo lokushisa lifikelela kwi-1100 ℃, isinyithi siya kwenziwa. Ibhekisa kuyo nayiphi na inkqubo yomatshini ebumba isinyithi esidibanisa enye okanye ngaphezulu iyafa, umz. ukuvula/okuvaliweyo kwidiyizi yokubumba, ukukhutshwa, ukuqengqeleka, njl. Xa iyancipha ukuya kuma-850 ℃, isinyithi siya kufudunyezwa kwakhona. Emva koko phinda umsebenzi oshushu kwelo qondo liphezulu lobushushu (1100℃). Ubuncinci bomlinganiselo womsebenzi oshushu ukusuka kwi-ingot ukuya kwi-billet yi-3 ukuya kwi-1.

Inkqubo yoNyango loBubushushu

Layisha i-preheat yokuphatha imathiriyeli kwi-furance yonyango lobushushu. Ubushushu ukuya kwi-900 ℃. Bamba kwiqondo lokushisa iiyure ezi-6 imizuzu emi-5. Ukucima i-oyile kunye nobushushu kwi-640 ℃. Emva koko i-Air-cool.

Iimpawu zeMechanical ze-X22CrMoV12-1 ibha yenkohliso (1.4923).

| RmAmandla okuqina (MPa) (+QT) | 890 |

| Rp0.20.2% amandla obungqina (MPa) (+QT) | 769 |

| KV- Amandla empembelelo (J) (+QT) | -60 ° 139 |

| A - Min. Ubude kukwaphuka (%) (+QT) | 21 |

| Ukuqina kweBrinell (HBW): (+A) | 298 |

Nawaphi na amabakala ezinto eziphathekayo, ngaphandle kokukhankanywa ngasentla, anokwenziwa ngokwemfuno yomthengi.