Umngxuma owenziweyo

Vula uMvelisi weDie Forgings eTshayina

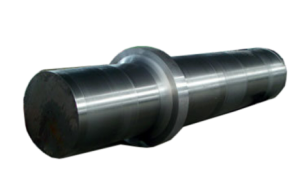

UMHLABA OMQHELEKILEYO / UMHLABA WENYATHELO/ I-SPINDLE / I-AXLE SHAFT

Iinkalo zesicelo ze-forging shaft zi

I-Shaft forgings (amacandelo omatshini) Ii-shaft forgings zizinto ezisilinda ezinxitywa embindini webheringi okanye embindini wevili okanye embindini wegiya, kodwa ezimbalwa zisikwere. Ishafti yinxalenye yomatshini exhasa indawo ejikelezayo kwaye ijikeleziswa ngayo ukuhambisa intshukumo, itorque okanye ixesha lokugoba. Ngokuqhelekileyo, yimeko yentonga yentsimbi, kwaye icandelo ngalinye linokuba nobubanzi obuhlukeneyo. Amacandelo omatshini okwenza ukunyakaza kwe-slewing kufakwe kwi-shaft. Chinese igama shaft forging uhlobo shaft, mandrel, drive shaft izinto ukusetyenziswa 1, carbon steel 35, 45, 50 kunye nezinye ezikumgangatho ophezulu carbon steel kwesakhiwo ngenxa iimpawu zayo eliphezulu olubanzi mechanical, izicelo ngaphezulu, apho 45 intsimbi isetyenziswa kakhulu ngokubanzi. Ukuze kuphuculwe iipropathi zayo zomatshini, ukulinganisa okanye ukucima kunye nokufudumala kufuneka kuqhutywe. Kwiishafu zesakhiwo ezingabalulekanga okanye zibe namandla aphantsi, iintsimbi ze-carbon structural ezifana ne-Q235 kunye ne-Q275 zingasetyenziswa. I-2, i-alloy steel I-alloy steel I-alloy steel ineempawu eziphezulu zoomatshini, kodwa ixabiso libiza kakhulu, lisetyenziselwa i-shafts kunye neemfuno ezizodwa. Ngokomzekelo, i-shafts ye-high-speed shafts isebenzisa ii-sliding bearings, eziqhelekileyo ezisetyenziselwa i-low-carbon alloy structural steels ezifana ne-20Cr kunye ne-20CrMnTi, inokuphucula ukunyanzeliswa kokugqoka kwijenali emva kokucima i-carburizing kunye nokucima; i-rotor shaft ye-turbo generator isebenza phantsi kobushushu obuphezulu, isantya esiphezulu kunye neemeko zomthwalo onzima. Ngeempawu ezilungileyo zobushushu obuphezulu obuphezulu, iintsimbi ze-alloy structural ezifana ne-40CrNi kunye ne-38CrMoAlA zihlala zisetyenziswa. I-blank of shaft ikhethwa kwi-forgings, ilandelwa yintsimbi ejikelezayo; kwizakhiwo ezinkulu okanye eziyinkimbinkimbi, insimbi etyhidiweyo okanye i-ductile iron ingaqwalaselwa. Ngokomzekelo, ukuveliswa kwe-crankshaft kunye ne-camshaft esuka kwi-iron ductile inenzuzo yexabiso eliphantsi, ukufunxa kakuhle kwe-vibration, uvakalelo oluphantsi kuxinzelelo loxinzelelo, kunye namandla amahle. Imodeli yomatshini we-shaft yi-beam, eyona nto ijikelezayo, ngoko ke uxinzelelo lwayo luhlala luyi-symmetric cycle. Iindlela zokungaphumeleli ezinokwenzeka zibandakanya ukwaphuka kokudinwa, ukwaphuka komthwalo ogqithisileyo, kunye ne-elastic deformation egqithisileyo. Ezinye iindawo ezinama-hubs zihlala zifakwe kwi-shaft, ngoko ke i-shafts ezininzi kufuneka zenziwe kwi-shafts stepped kunye nobuninzi bomatshini. UHlelo loLwakhiwo Uyilo loLwakhiwo Uyilo lwesakhiwo seshafti linyathelo elibalulekileyo ekumiseleni imilo efanelekileyo kunye nemilinganiselo yesakhiwo ngokubanzi yeshafti. Iqulethwe uhlobo, ubungakanani kunye nesikhundla senxalenye efakwe kwi-shaft, indlela yokulungiswa kwenxalenye, indalo, isalathiso, ubungakanani kunye nokusabalalisa komthwalo, uhlobo kunye nobukhulu bokuthwala, indawo engenanto ye-shaft, inkqubo yokuvelisa kunye nendibano, ukufakwa kunye nokuthutha, i-shaft I-deformation kunye nezinye izinto zihambelana. Umyili unokuyila ngokweemfuno ezithile ze-shaft. Ukuba kuyimfuneko, amacebo amaninzi anokuthelekiswa ukuze ukhethe eyona ndlela ilungileyo yoyilo.

Ezi zilandelayo ziyimigaqo yoyilo lwesakhiwo se-shaft ngokubanzi

1. Gcina izinto, ukunciphisa ubunzima, kwaye usebenzise imilo elinganayo-amandla. Ubume bomlinganiso wecandelo elilinganayo okanye elikhulu.

I-2, kulula ukuyibeka ngokuchanekileyo, ukuzinza, ukudibanisa, ukudibanisa kunye nokulungelelanisa iindawo kwi-shaft.

3. Sebenzisa imilinganiselo eyahlukeneyo yesakhiwo ukunciphisa uxinzelelo kunye nokuphucula amandla.

4. Kulula ukwenza kunye nokuqinisekisa ukuchaneka.

Ukuhlelwa kweeshafti Iishafu eziqhelekileyo zinokwahlulwa zibe yi-crankshafts, i-shafts straight, i-shafts flexible, i-shafts eqinile, i-shafts egobileyo, i-shafts eqinile, kunye ne-flexible shafts (i-flexible shafts) ngokuxhomekeke kwisakhiwo se-shaft.

I-shaft ethe tye inokwahlulwa ngakumbi

1 shaft, ephantsi komzuzu wokugoba kunye netorque, kwaye yeyona shaft ixhaphakileyo koomatshini, abanje ngeeshafti kwizinciphisi zesantya ezahlukeneyo.

2 mandrel, esetyenziselwa ukuxhasa iindawo ezijikelezayo kuphela ukuthwala umzuzu ukugoba ngaphandle kokudlulisa torque, ezinye ukujikeleza mandrel, ezifana ekseni yesithuthi sikaloliwe, njl, ezinye mandrel ayijikelezi, ezifana shaft ukuxhasa pulley.

3 Ishafu yothumelo, ikakhulu esetyenziselwa ukuhambisa itorque ngaphandle komzuzu wokugoba, njenge-axis ende ye-optical kwi-crane ehambayo, ishaft yemoto, njl.

Izinto eziphathekayo ze-shaft ziyi-carbon steel okanye i-alloy steel, kunye ne-ductile iron okanye i-alloy cast iron nayo ingasetyenziswa. Umthamo wokusebenza we-shaft ngokubanzi uxhomekeke kumandla kunye nokuqina, kwaye isantya esiphezulu sixhomekeke ekuzinzeni kwe-vibration. Isicelo Ukuqina kwe-torsional Ukuqina kwe-torsional ye-shaft kubalwa njengobungakanani be-torsional deformation ye-shaft ngexesha lokusebenza, kulinganiswe ngokwe-angle yokujikeleza ngemitha yobude be-shaft. I-torsional deformation ye-shaft kufuneka ichaphazele ukusebenza kunye nokuchaneka kokusebenza komatshini. Ngokomzekelo, ukuba i-angle ye-torsion ye-camshaft ye-injini yokutsha yangaphakathi inkulu kakhulu, iya kuchaphazela ukuvulwa okuchanekileyo kunye nexesha lokuvala i-valve; i-angle ye-torsion ye-shaft yothumelo ye-gantry crane motion mechanism iya kuchaphazela i-synchronism yevili lokuqhuba; Ubunzima obukhulu be-torsional bufunekayo kwi-shafts esemngciphekweni we-torsional vibration kunye ne-shafts kwinkqubo yokusebenza.

Iimfuno zobugcisa 1. Ukuchaneka komatshini

1) Ukuchaneka komgangatho Ukuchaneka kwe-dimensional yamacandelo e-shaft ikakhulu ibhekiselele kububanzi kunye nokuchaneka kwe-dimensional ye-shaft kunye nokuchaneka kwe-dimensional yobude be-shaft. Ngokweemfuno zokusetyenziswa, ukuchaneka kwedayimitha yejenali ephambili idla ngokuba yi-IT6-IT9, kwaye ijenali echanekileyo nayo ifikelela kwi-IT5. Ubude be-shaft budla ngokuchazwa njengobungakanani obuqhelekileyo. Ngobude besinyathelo ngasinye se-shaft stepped, ukunyamezela kunokunikezelwa ngokweemfuno zokusetyenziswa.

2) Ukuchaneka kwejiyometri Amalungu e-Shaft axhaswa ngokubanzi kwiijenali ezimbini. Ezi jenali zimbini zibizwa ngokuba ziijenali zenkxaso kwaye zikwayireferensi yendibano yeshaft. Ukongeza kokuchaneka kwe-dimensional, ukuchaneka kwejometri (ukujikeleza, i-cylindricity) yejenali exhasayo iyafuneka ngokubanzi. Kwiijenali zokuchaneka ngokubanzi, impazamo yejometri kufuneka ikhawulelwe kwi-diameter tolerance. Xa iimfuno ziphakamileyo, amaxabiso okunyamezela avunyelwe kufuneka acaciswe kwinxalenye yomzobo.

3) Ukuchaneka okuthe ngqo kwezikhundla Ukubambisana phakathi kweejenali zokukhwelana (iijenali zamalungu e-asembly drive) kwiindawo zeshaft ngokunxulumene neejenali zenkxaso yimfuneko eqhelekileyo yokuchaneka kwazo zombini. Ngokuqhelekileyo, i-shaft echanekileyo ngokuchanekileyo, ukuchaneka okuhambelanayo ngokubhekiselele kwi-radial runout yejenali yenkxaso ngokuqhelekileyo yi-0.01-0.03 mm, kwaye i-shaft ephezulu-precision yi-0.001-0.005 mm. Ukongezelela, ukuchaneka kwe-mutual positional kuchaneka kwakhona i-coaxiality yendawo yangaphakathi nangaphandle ye-cylindrical, i-perpendicularity ye-axially positioned end faces kunye nomgca we-axial, kunye nokunye okunjalo. I-2, uburhabaxa bomphezulu Ngokokuchaneka komtshini, isantya sokusebenza, iimfuno zobunzima bomphezulu weendawo ze-shaft nazo zahlukile. Ngokubanzi, uburhabaxa bomphezulu uRa wejenali exhasayo yi-0.63-0.16 μm; uburhabaxa bomphezulu iRa yejenali ehambelanayo yi-2.5-0.63 μ m.

Itekhnoloji yokucubungula i-1, ukukhethwa kweendawo ze-shaft ye-shaft ye-shaft parts, Ikakhulu ngokusekelwe kumandla, ukuqina, ukuxhathisa ukunxiba kunye nenkqubo yokuvelisa i-shaft, kunye nokuzabalazela uqoqosho.

Izinto eziqhelekileyo ezisetyenziswayo: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 |42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30NiCrMo12 |22NiCrMoV|EN 1.4201 |42CrMo4

UMHLABA OMQHILEYO

I-Shaft enkulu eyakhiweyo ukuya kuthi ga kwi-30 T.. Ukunyamezelwa kweringi ngokuqhelekileyo -0/+3mm ukuya ku-+10mm kuxhomekeke kubungakanani.

●Zonke iiMetals zinamandla okubumba ukuvelisa iringi yomgunyathi kwezi ntlobo zealloyi zilandelayo:

● Intsimbi yealloyi

●Intsimbi yekhabhoni

●Intsimbi engenasici

IZAKHONO ZOKUMHLABA EZENZIWEYO

Izinto eziphathekayo

MAX DIAMETER

MAX WIGHT

Ikhabhoni, intsimbi yentsimbi

1000mm

20000 kgs

Yenziwe ngentsimbi eshayinayo

800mm

15000 kgs

I-Shanxi DongHuang Wind Power Flange Manufacturing Co., LTD., Njengomvelisi obhalisiweyo we-ISO obhalisiweyo, isiqinisekiso sokuba i-forging kunye / okanye imivalo ifana kumgangatho kwaye ayinayo i-anomalies eyingozi kwiipropati zoomatshini okanye i-machining Properties yezinto.

Ityala:

IBanga leNsimbiI-BS EN 42CrMo4

I-BS EN 42CrMo4 iNsimbi yengxubevange yeeNgcaciso ezifanelekileyo kunye neziLinge

| 42CrMo4/1.7225 | C | Mn | Si | P | S | Cr | Mo |

| 0.38-0.45 | 0.60-0.90 | 0.40 ubuninzi | 0.035 ubuninzi | 0.035 ubuninzi | 0.90-1.20 | 0.15-0.30 |

| I-BS EN 10250 | Umbandela onguNombolo. | I-DIN | I-ASTM A29 | I-JIS G4105 | BS 970-3-1991 | BS 970-1955 | AS 1444 | UKUBALULEKILE | GB |

| 42CrMo4 | 1.7225 | 38HM | 4140 | I-SCM440 | 708M40 | EN19A | 4140 | 42CD4 | 42CrMo |

Ibakala lentsimbi 42CrMo4

Usetyenziso

Ezinye iindawo eziqhelekileyo zokusetyenziswa kwe-EN 1.4021

Iinxalenye zempompo kunye neValve, i-Shafting, i-Spindels, i-Piston rods, iFittings, i-Stirrers, i-Bolts, i-Nuts

EN 1.4021 umsesane owakhiweyo, iintsimbi zentsimbi engatyiwa ngumsesane wokuSlewing ring

Ubungakanani: φ840 x L4050mm

Ukuqulunqa (umsebenzi oshushu ) Ukuziqhelanisa , Inkqubo yoNyango lokutshisa

| Ukuqulunqa | 1093-1205℃ |

| Ukuhlaziya | 778-843℃ eziko elipholileyo |

| Ukufudumeza | 399-649℃ |

| Ukuqheleka | 871-898 ℃ umoya opholileyo |

| Qinisekisa | 815-843℃ ukucima amanzi |

| Nciphisa Uxinzelelo | 552-663℃ |

| Ukucima | 552-663℃ |

I-DIN 42CrMo4 i-alloy Steel Mechanical Properties

| Ubungakanani Ø mm | Uxinzelelo lwesivuno | Uxinzelelo lokugqibela, | Elongation | Ubulukhuni HB | Ukuqina |

| Rp0.2,N/nn2, umz. | Rm,N/nn2 | A5,%, min. | KV, Joule, min. | ||

| <40 | 750 | 1000-1200 | 11 | 295-355 | 35 nge-20ºC |

| 40-95 | 650 | 900-1100 | 12 | 265-325 | 35 nge-20ºC |

| >95 | 550 | 800-950 | 13 | 235-295 | 35 nge-20ºC |

| Rm - Amandla okuqina (MPa) (Q +T) | ≥635 |

| Rp0.2 0.2% amandla obungqina (MPa) (Q +T) | ≥440 |

| I-KV - Amandla empembelelo (J) (Q +T) | +20 ° |

| A - Min. Ubude kukwaphuka (%)(Q +T) | ≥20 |

| Z - Ukunciphisa icandelo lomnqamlezo kwi-fracture (%) (N+Q +T) | ≥50 |

| Ukuqina kweBrinell (HBW): (Q +T) | ≤192HB |

IINKCUKACHA EZONGEZELELWEYO

CELA ISICATSHULWA NAMHLANJE

OKANYE CALL: 86-21-52859349