Litaba tsa indasteri

-

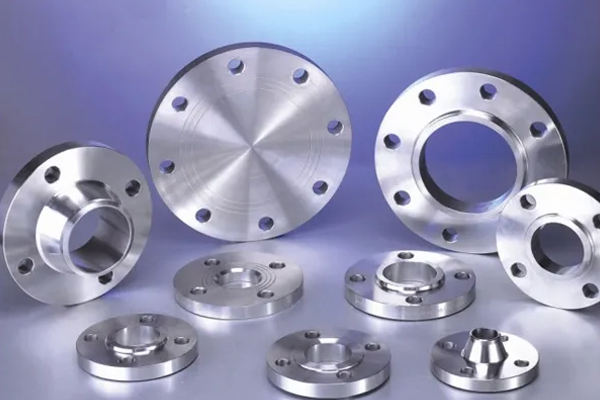

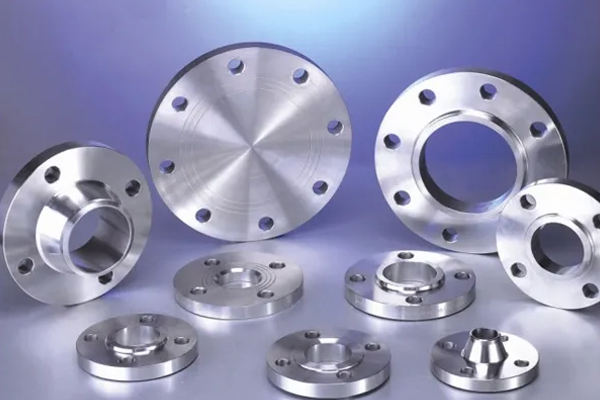

Large caliber stainless steel flange bokae?

Flange e kholo ea tšepe e sa hloekang e nang le tlhokomelo e bonolo, tlhokomelo e bonolo, lisebelisoa tse ntle haholo, khokahano ha e bonolo ho libopeho tsa deformation, ke mofuta o tsebahalang haholo ke bareki ba lihlahisoa tse kholo tsa li-caliber flange, lisebelisoa tsa liphaephe, petrochemical, mochini oa metallurgical, aerospace...Bala haholoanyane -

Mokhoa oa ho hlahloba lisebelisoa tse tala

Forgings pele forging processing, e hloka ho feta ka mokhoa o itseng, e tlameha ho lekola boleng ba thepa ea eona e tala, ho netefatsa hore thepa e tala ha e na mathata a boleng pele ho ts'ebetso e latelang, joale re tla sheba hore na e na le litlhoko life. 一Litlhoko tse akaretsang tsa ho forging thepa e tala. 1...Bala haholoanyane -

Melemo ea li-flange tsa tšepe e sa hloekang e hlahisoa

(1) Li-flange tsa tšepe e sa hloekang li na le ho thatafala ha tlase le data e tiileng, joalo ka tšepe e tlase ea khabone le motsoako oa aluminium. E na le boima bo tlase le boima bo botle. Ho thata ho khaola li-chips mme ho bonolo ho theha li-chips nakong ea ho itšeha, e amang boleng ba bokaholimo. Ka hona, flan ea tšepe e sa hloekang ...Bala haholoanyane -

Sesosa sa ho lutla ha flange ke eng?

Sesosa sa ho lutla ha flange ke eng? Basebetsi ba fektheri ea Fora ba ile ba akaretsa mabaka a latelang a supileng a ho lutla, ka tšepo ea ho thusa metsoalle e hlokang. 1, lebaka la ho lutla ha flange: molomo o fosahetseng Lenonyeletso le thekeselang ke moo phala le flange li leng teng, empa li-flange tse peli ha li tsepame. Flange ke n...Bala haholoanyane -

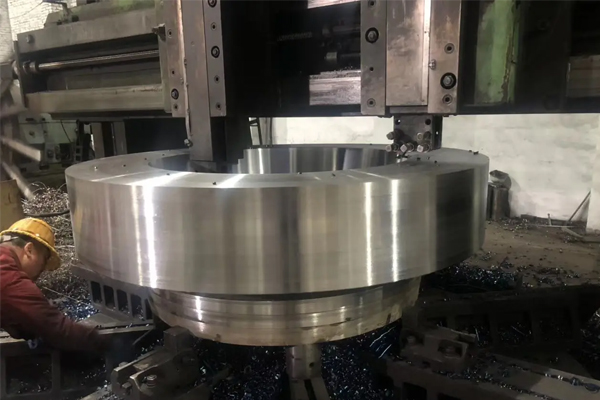

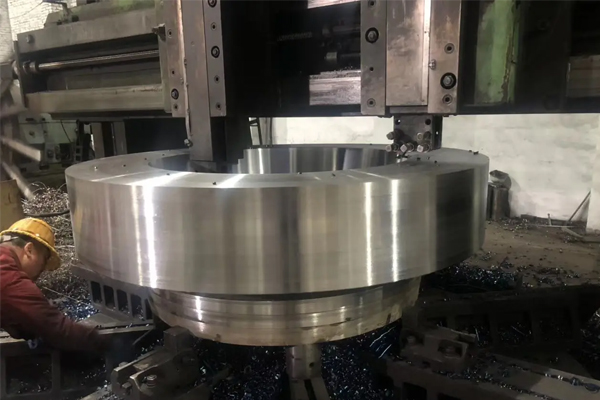

Stainless steel flange die forging thepa le litšobotsi tsa kopo

Thepa ea mechine ea forgings e phahame ho feta e hlahisoang ka hamore. Tlhahiso e phahameng; Tahlehelo e fokolang ea tšepe; Hammer forging die e entsoe ka likarolo tse peli tsa lefu le ka holimo le ka tlase, mochini o otlolohileng o entsoe ka punch le halofo e 'meli ea motsoako oa likarolo tse tharo tsa ...Bala haholoanyane -

Lisebelisoa tsa forging ke life?

Forgings ke workpiece kapa se na letho fumanoa ka forging deformation ea billets tšepe. Lisebelisoa tsa mechine ea li-billet tsa tšepe li ka fetoloa ka ho sebelisa khatello ea ho hlahisa deformation ea polasetiki. Forgings e ka aroloa ka forging e batang ea forging e futhumetseng le forging e chesang ho latela mocheso oa ...Bala haholoanyane -

Ho theha litšobotsi tsa theknoloji ea tlhahiso ea stamping

Ho hatakela ke e 'ngoe ea mekhoa ea mantlha ea ho sebetsa ka polasetiki ea tšepe. E sebelisoa haholo-holo bakeng sa ho lokisa li-sheet forgings, kahoo hangata e bitsoa sheet stamping. Hobane mokhoa ona o etsoa ka mocheso oa kamore, o boetse o bitsoa serame se batang. Leha mabitso ana a mabeli a kaholimo e se setempe se nepahetseng haholo...Bala haholoanyane -

Mokhoa oa ho khetholla boleng ba ho forging

Mosebetsi o ka sehloohong oa tlhahlobo ea boleng ba forgings le tlhahlobo ea boleng ke ho hlwaya boleng ba forgings, ho sekaseka lisosa tsa mefokolo ea forgings le mehato ea thibelo, ho sekaseka lisosa tsa mefokolo ea forgings, ho beha mehato e sebetsang ea ho thibela le ho ntlafatsa, e leng tsela ea bohlokoa ea ho ...Bala haholoanyane -

Ho na le mefuta e meraro ea libaka tse tiisitsoeng tsa flange

Karolo e kopanyang phala le phala e kopantsoe le pheletsong ea phala. Ho na le masoba ka har'a flange 'me liboutu li tšoara li-flange tse peli hammoho. Gasket e tiisa pakeng tsa flanges. Lisebelisoa tsa liphaephe tse nang le liphaephe li bua ka liphaephe tse nang le li-flanges (li-flanges kapa manonyeletso). E ka 'na ea etsoa, ea khoele kapa ea chesoa. The fla...Bala haholoanyane -

Sistimi e tloaelehileng bakeng sa flange

Tekanyetso ea machaba ea peipi ea flange haholo-holo e na le litsamaiso tse peli, e leng tsamaiso ea liphaephe tsa Europe tse emeloa ke DIN ea Jeremane (ho kenyeletsoa le mehleng ea mehleng ea Soviet Union) le tsamaiso ea liphaephe tsa Amerika tse emetsoeng ke phala ea Amerika ea ANSI. Ntle le moo, ho na le liphaephe tsa liphaephe tsa Japane tsa JIS, empa ke ...Bala haholoanyane -

Tsebo ea likheo tsa flange

Flange blank, flange blank ke mokhoa o tloaelehileng oa tlhahiso hona joale, liaocheng ntshetsopeleng zone hongxiang stamping likarolo fektheri bapisoa le mokhoa o tloaelehileng oa tlhahiso ea flange, e na le melemo e latelang e totobetseng 1) thepa e tala ho ea ka tlhokahalo ea bareki bohle ba sebelisa ma...Bala haholoanyane -

Setšoantšo sa ho futhumatsa tšepe ea ingot e sebelisoang ho forging

Li-forging tse kholo tsa mahala le lisebelisoa tse phahameng tsa tšepe tse entsoeng ka tšepe li entsoe haholo-holo ka ingot ea tšepe, e ka aroloa ka ingot e kholo le e nyenyane ho latela tlhaloso ea ingot ea tšepe. Ka kakaretso boima bo boholo ho feta 2t ~ 2.5t, bophara bo boholo ho feta 500mm ~ 550mm ingot e bitsoang ingot e kholo, oth ...Bala haholoanyane