Litaba tsa indasteri

-

Phello ea ho itlotsa ka botenya ts'ebetsong ea ho forging ke efe?

Khohlano ea ho theha ke likhohlano lipakeng tsa litšepe tse peli tsa sebopeho le thepa e fapaneng (alloys), lipakeng tsa tšepe e bonolo (workpiece) le hard metal (die). Tabeng ea ho se lubrication, ke ho kopana khohlano ea mefuta e 'meli ea tšepe holim oxide filimi; Tlas'a boemo ba lubrication, conta ...Bala haholoanyane -

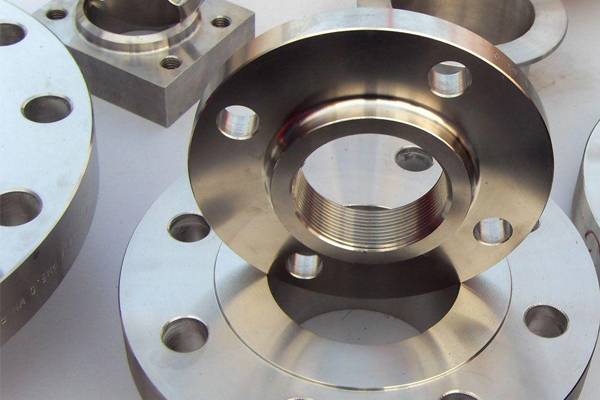

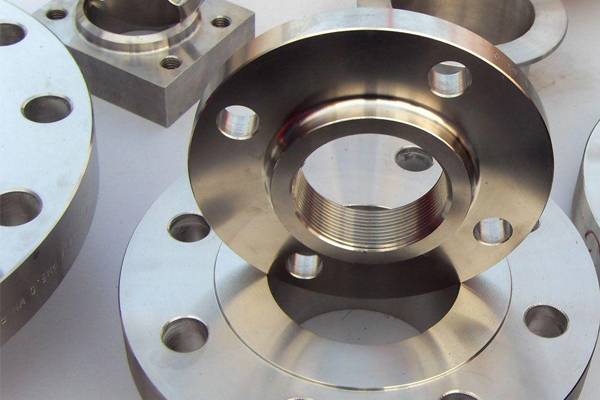

Tlhaloso e qaqileng ea li-flange tse sebelisoang hangata Chaena

1. Ho ea ka maemo a indasteri ea mechine, mefuta ea li-flange ke: mofuta oa poleiti e sephara-welded flange, butt-welded flange, integral flange, butt-welded ring-plate mofuta oa loose sleeve flange, flat-welded ring-plate mofuta o hlephileng oa sleeve, flanged ring-plate mofuta o hlephileng oa sleeve flange, sekoahelo sa flange. 2...Bala haholoanyane -

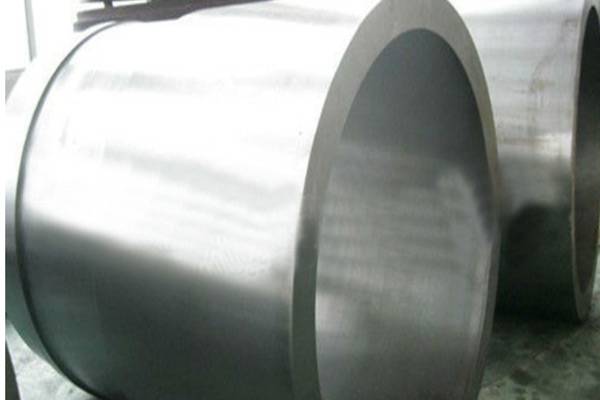

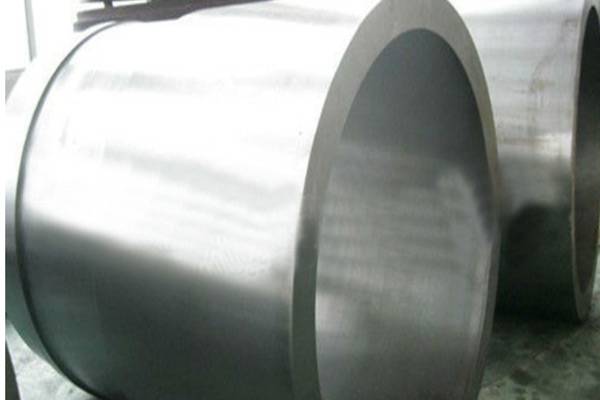

Ke mefuta efe ea shaft forgings e fihlelang litlhoko?

Axial forging ke mofuta oa kopo e pharaletseng ea li-forgings, tse kang axial plus e na le ts'ebetso e ntle ea ts'ebetso, m leha e le efe porosity ka ts'ebetso, ha ho na liphoso tse ling, kahoo ha e na ponahalo e ntle feela, e nang le botle, mona ke mokhoa oa ho u tsebisa hore u lumellane le litlhoko tsa axial forgings ho ratoa. Pele...Bala haholoanyane -

Mokhoa oa ho tiisa oa hydraulic cylinder forging

Lebaka leo ka lona li-hydraulic cylinder forgings li hlokang ho koaloa ke ka lebaka la boteng ba ho lutla ka hare le ho lutla ka ntle. Ha ho na le ho lutla ka hare le ho lutla ka ntle ka har'a silinda ea hydraulic, ho tla lebisa bophahamong ba "hydraulic cylinder's cavity" le ho sebetsa hantle ka ...Bala haholoanyane -

Fektheri ea flange e na le theknoloji efe ea ho forging?

Flange fektheri ke khoebo ea tlhahiso e hlahisang li-flanges. Li-flanges ke likarolo tse hokahaneng pakeng tsa liphaephe, tse sebelisetsoang ho hokahanya pakeng tsa liphaephe. E boetse e na le thuso bakeng sa flange e kenang le ho tsoa ha lisebelisoa bakeng sa ho hokahanya lisebelisoa tse peli. Theknoloji ea tlhahiso ...Bala haholoanyane -

Joang ho etsa forgings ea tšepe e sa hloekang?

Ho nepahala ha litšepe tse makukuno kapa tse se nang tšepe ho phahame. Tšebeliso ea theknoloji e tsoetseng pele le lisebelisoa li ka finyella ho honyenyane kapa ho se be le ho itšeha. Lisebelisoa tsa tšepe tse sebelisoang ho qhekella li lokela ho ba le polasetiki e ntle, e le hore tlas'a ketso ea matla a ka ntle, deformation ea polasetiki e ka hlahisoa ka ...Bala haholoanyane -

Molao-motheo oa ho tiisa le litšobotsi tsa flange

Ho tiisoa ha li-flanges tse bataletseng esale e le taba e chesang e amanang le litšenyehelo tsa tlhahiso kapa melemo ea moruo ea likhoebo. Leha ho le joalo, bofokoli bo ka sehloohong ba moralo oa li-flange tse nang le tjheseletso e sephara ke hore ha li tsoe. Ena ke bofokoli ba moralo: khokahano e matla, le meroalo ea nako le nako, joalo ka ...Bala haholoanyane -

Ke eng e lokelang ho hlokomeloa ha ho hlahlojoa li-forgings pele ho phekolo ea mocheso?

Tlhahlobo pele ho tharollo ea mocheso oa tharollo ke ts'ebetso ea tlhahlobo ea pele ho lekola boleng le boholo ba sehlahisoa se felileng ho ea ka maemo a tekheniki, motaki oa forging le karete ea ts'ebetso ka mor'a hore mokhoa oa ho theha o felile. Tlhahlobo e khethehileng e lokela ho lefa ...Bala haholoanyane -

Mokhoa oa ho fumana mathata a ho sebetsana le flange ea tšepe e sa hloekang

Pele ho tsohle, pele u khetha mochini oa ho phunya, sheba mathata a ts'ebetso ea flange ea tšepe e sa hloekang. Fumana hore bothata bo ka ba bo nepahetseng haholo, bo potlakileng haholo ho fumana ts'ebeliso ea boro. Mathata a ho sebetsa ha flange ea tšepe e sa hloekang ke afe? Thipa e khomarelang: tšepe e sa hloekang...Bala haholoanyane -

Mokhoa oa ho qhekella ke ofe?

1. Isothermal forging ke ho boloka mocheso oa billet o sa fetohe nakong eohle ea ho theha. Isothermal forging e sebelisetsoa ho nka monyetla ka polasetiki e phahameng ea litšepe tse itseng ka mocheso o sa fetoheng kapa ho fumana meaho le thepa e itseng. Isothermal forging e hloka hlobo ...Bala haholoanyane -

Litšitiso tse kholo tsa metsi joalo ka mokhoa oa ho tima ho pholile bakeng sa forgings?

1) setšoantšong sa phetoho ea austenite isothermal ea sebaka se tloaelehileng, ke hore, hoo e ka bang 500-600 ℃, metsi a sethaleng sa filimi ea mouoane, sekhahla sa ho pholisa ha se potlake ka ho lekaneng, hangata se baka ho pholile ho sa lekaneng le ho se lekane ha lebelo la ho pholisa le ho thehoa ha "bonolo ntlha".Bala haholoanyane -

Ke mofuta ofe oa khokahanyo ea bolt eo flange ea tšepe e sa hloekang e sebelisang?

Hangata bareki ba botsa: khokahanyo ea tšepe e sa hloekang ea flange ho khetha liboutu tsa tšepe tse sa hloekang? Hona joale ke tla ngola seo ke ithutileng sona ho arolelana le uena: Boitsebiso ha bo amane letho le thepa ea li-flange bolts, ho latela tsamaiso ea Europe HG20613-97 "peipi ea tšepe ea tšepe e nang le li-fasteners (the...Bala haholoanyane