1. Moqapi oa isothermalke ho boloka mocheso oa billet o sa fetohe nakong eohle ea ho theha.Moqapi oa isothermale sebelisoa ho nka monyetla ka polasetiki e phahameng ea litšepe tse itseng mochesong o sa fetoheng kapa ho fumana meaho le thepa e itseng. Isothermal forging e hloka hore hlobo le billet li bolokoe mocheso o sa khaotseng hammoho, o hlokang litšenyehelo tse phahameng 'me o sebelisoa feela bakeng sa mekhoa e khethehileng ea ho etsa le ho hatella, joalo ka ho etsa superplastic.

2. Ho qapae ka fetola sebopeho sa tšepe le ho ntlafatsa ts'ebetso ea tšepe. Kamoraho qapa ho chesaingot, boemo ba pele ba ho lahla bo hlephileng, pore, micro crack e kopantsoe kapa e cheselitsoe; Khalase ea pele ea dendritic e robehile ho etsa hore lijo-thollo li be ntle. Ka nako e ts'oanang, fetola karohano ea pele ea carbide le kabo e sa lekanang, e le hore mokhatlo o tšoane, e le ho fumana ka hare ho teteaneng, junifomo, e ntle, ts'ebetso e ntle e akaretsang, ts'ebeliso e tšepahalang ea forgings. Kamoraho qapa ho chesadeformation, tšepe ke fibrous sebopeho; Ka mor'a deformation e batang ea ho qapa, likristale tsa tšepe li bontša tatellano.

3.forgingke ho etsa hore polasetiki ea tšepe e phalle 'me e be sebopeho se lakatsehang sa workpiece. Bophahamo ba tšepe ha bo fetohe ka mor'a hore polasetiki e phalle ka matla a ka ntle, 'me tšepe e lula e phalla ho ea karolong ea ho hanyetsa bonyane. Ha ho etsoa tlhahiso, sebopeho sa workpiece se atisa ho laoloa ho ea ka melao ena, 'me ho senyeha ha setšoantšo se ferekanyang, ho tsosolosa, ho khumama le ho hula ho tebileng hoa phethahala.

4.theforging workpieceboholo bo nepahetse, bo loketse ho hlophisa tlhahiso ea bongata.Lefu la ho qhekella, extrusion, stamping le lits'ebetso tse ling tsa boholo ba sebopeho sa hlobo li nepahetse ebile li tsitsitse. Mechini e phahameng e sebetsang hantle ea ho qhekella le mohala oa tlhahiso ea othomathike o ka sebelisoa ho hlophisa tlhahiso e khethehileng ea bongata kapa tlhahiso ea bongata.

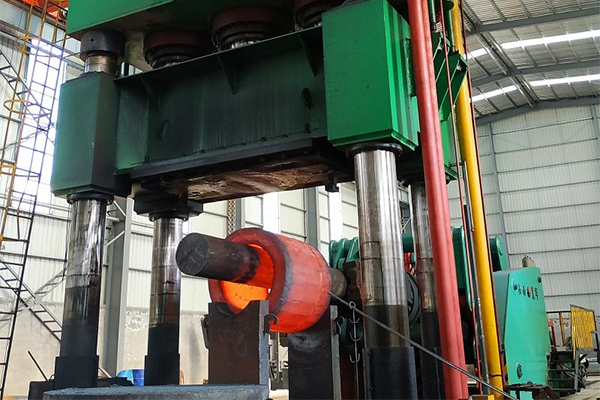

5.Mokhoa oa tlhahiso eaforginge kenyelletsa ho koala, ho futhumatsa le ho lokisa esale pele ho qhekella letho pele ho etsoa; Phekolo ea mocheso, ho hloekisa, ho lekanya le ho hlahloba workpiece ka mor'a ho theha. Mechini e sebelisoang hangata e na le hamore ea forging, hydraulic press le mochini oa khatiso. Hamore ea forging e na le lebelo le leholo la ts'usumetso, e loketseng phallo ea polasetiki ea tšepe, empa e tla hlahisa ho thothomela; Mochine oa khatiso oa hydraulic o sebelisa static forging, o na le molemo oa ho theha ka tšepe le mokhatlo oa ntlafatso, mosebetsi o tsitsitse, empa tlhahiso e tlaase; Mochine oa khatiso o na le stroke se tsitsitseng, seo ho leng bonolo ho se hlokomela ka mochine le ho iketsetsa.

Nakong e tlang, thetheknoloji ea ho thehae tla ntlafatsa boleng ba ka hare baho qapa likarolo, hlahisa ho nepahalaforgingle theknoloji e nepahetseng ea setempe, ho ntshetsa pelethepa ea ho forgingleho qapa tlhahisotsamaisana le tlhahiso e phahameng le degree ea automation, nts'etsopeleflexible forgingho theha sistimi, le ho nts'etsapele e nchathepa ea ho forgingleforging processingmekhoa. Ho ntlafatsa boleng ba ka hare baforgings, ke haholo-holo ho ntlafatsa thepa ea bona ea mechine (matla, polasetiki, ho thatafala, matla a mokhathala) le ho tšepahala. Sena se hloka kopo molemo ka ho fetisisa tsa tšepe polasetiki deformation khopolo; Sebelisa lisebelisoa tsa boleng bo holimo; Ho futhumatsa ho nepahetseng pele ho forging le kalafo ea mocheso ea forging; Teko e matla le e pharalletseng e sa senyeheng ea forgings.

Nako ea poso: Jan-25-2021