1. isothermal forgingiri mukuita kwese kwekugadzira tembiricha yebillet kuchengetedza kukosha kwekugara.Isothermal forgingndeye kushandisa zvizere plastiki yakakwira yemamwe simbi patembiricha imwechete, kana kuwana chaiyo microstructure uye zvivakwa. Isothermal forging inoda kugara tembiricha yekufa uye billet pamwe chete, iyo inoda mutengo wakakwira uye inoshandiswa chetespecial forgingmaitiro, senge superplastic kugadzira.

2.forginginogona kushandura chimiro chesimbi, kuvandudza kushanda kwesimbi. Mushurekupisa kuumba, iyo yepakutanga yakakanda yakasununguka, pores, micro-cracks uye zvichingodaro zvakabatanidzwa kana welded; Iwo ekutanga dendritic makristasi akatyoka uye zviyo zvinova zvakanaka. Panguva imwecheteyo shandura yepakutanga carbide segregation uye kusaenzana kugovera, ita chimiro yunifomu, kuitira kuti uwane iyo yemukati dense, yunifomu, yakanaka, yakanaka yakazara mashandiro, yakavimbika kushandiswa kwefogi. Mushure mekupisa kwekugadzira deformation, simbi ine fibrous tishu; Mushure mekutonhora kwekugadzira deformation, makristasi esimbi anoratidza kurongeka.

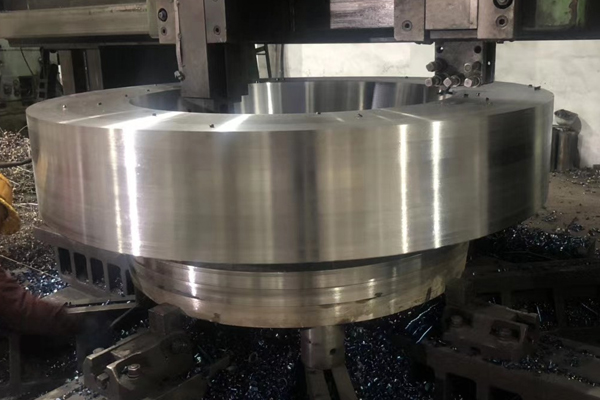

3. forgingndiko kuita simbi yepurasitiki kuyerera uye kuita chimiro chinodiwa che workpiece. Huwandu hwesimbi hunogara huripo mushure mekuyerera kwepurasitiki kunokonzerwa nesimba rekunze, uye simbi inogara ichiyerera ichienda kune chikamu chine kushomeka kushoma. Mukugadzira, iyo workpiece chimiro chinowanzodzorwa zvinoenderana nemirairo iyi kuona inoshungurudza kudhirowa, gomba kuwedzera, kukotama, kudhirowa uye kumwe kudhirowa.

4. forgingkunze kweiyo workpiece saizi ndeyechokwadi, inoenderana neruzhinji kugadzirwa kwesangano.Kufa kuhura, extrusion, stamping uye mamwe maapplication ekugadzira mold saizi yakarurama, yakagadzikana. Kunyanya kushanda zvakanaka kwekugadzira muchina uye otomatiki yekugadzira mutsara wekugadzira inogona kushandiswa kuronga nyanzvi yekugadzira misa kana kugadzirwa kwakawanda.

5. forgingmaitiro ekugadzira anosanganisira kugadzira billet blanking,forgingbillet kupisa uye pretreatment vasati vaumba; Kurapa kwekupisa, kuchenesa, kuenzanisa uye kuongororwa kweworkpiece mushure mekugadzira. Inowanzo shandiswa kugadzira muchina une nyundo yekugadzira, hydraulic press uye mechanic press. Kugadzira nyundo ine hombe yekumhanyisa kumhanya, inoenderana nesimbi yepurasitiki kuyerera, asi inoburitsa vibration; Hydraulic press ine static forging, inobatsira kugadzira kuburikidza nesimbi uye kugadzirisa sangano, basa rakadzikama, asi kubereka kwakaderera; Mechanical press stroke yakagadziriswa, iri nyore kuona mechanization uye otomatiki.

Mune ramangwana,forginguye tekinoroji yekutsikirira inozovandudza mukati memhando yekugadzira nekutsikirira zvikamu, kuvandudza tekinoroji yekugadzira uye yekutsikisa tekinoroji, kugadzira michina yekugadzira nekugadzira mutsara wekugadzira ine chibereko chepamusoro uye otomatiki, kuvandudza kuchinjika.forginguye kudzvanya system, gadzira nyowaniforgingzvinhu uyeforgingnzira dzekugadzirisa. Kuvandudza mukati memhando yekugadzira zvikamu zvinonyanya kuvandudza maitiro avo emagetsi (simba, plastiki, kuoma, kuneta simba) uye kuvimbika. Izvi zvinoda kushandiswa zviri nani kwesimbi plastiki deformation theory; Kushandiswa kwezvinhu zviri nani zvemhando yepamusoro; Ndizvozvopre-forgingkupisa uye kugadzira kupisa kurapwa; Kuwedzera kuomarara uye kwakawedzera kusiri-kuparadza kuyedzwa kwezvikamu zvekuumba.

Nguva yekutumira: Oct-18-2021