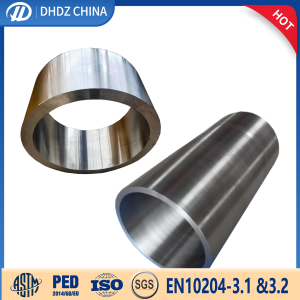

Forged Ring

Vhura Die Forgings Mugadziri muChina

MANGIRI AKAKORWA MSINGANA AKAREDWA /FORGED RING / GEAR RING

Iyo minda yekushandisa yemhete forgings ndeiyi:

Diesel injini mhete forgings: mhando yedhiziri forgings, dizeli injini yedhiziri imhando yemachina emagetsi, inowanzoshandiswa seinjini. Kutora injini dzedhiziri semuenzaniso, mafogiji anoshandiswa cylinder head, main journal, crankshaft end flange inobuda end shaft, yekubatanidza tsvimbo, piston rod, piston head, crosshead pin, crankshaft transmission gear, giya remhete, giya repakati uye pombi yedhayi. Anopfuura marudzi gumi emuviri.

Marine ring forgings: Marine forgings akakamurwa kuita mapoka matatu, main forgings, shaft forgings uye rudder forgings. Iwo main unit forgings akafanana nedhiziri forgings. Iyo shaft forging ine thrust shaft, yepakati shaft, nezvimwe zvakadaro. Mafogi emarudhi masisitimu anosanganisira rudder stock, rudder stock, uye mapini ekudzosa.

Weapon ring forgings: Forgings inotora chinzvimbo chakakosha kwazvo muindasitiri yezvombo. Nehuremu, 60% yematangi anogadzirwa. Pfuti mbiya, muzzle retractor uye stern in artillery, pfuti mbiya uye triangular bayonet mune zvombo zvevacheche, yakadzika bhomba remvura yekuvhura uye chigaro chakamisikidzwa cheroketi nepasi pemvura, simbi isina tsvina yevharuvhu muviri wenyukireya wepasi pemvura inotonhorera inotonhorera, mabhomba, Pfuti, nezvimwewo, zvigadzirwa zvekunyepedzera. Mukuwedzera kune simbi yekugadzira, zvombo zvinogadzirwawo kubva kune zvimwe zvinhu.

Petrochemical mhete forgings: Forgings ane huwandu hwakasiyana hwekushandisa mune petrochemical michina. Zvakadai semanhole uye maflange ematangi ekuchengetera spherical, akasiyana chubhu mashiti anodiwa pakupisa kupisa, forging silinda (pressure midziyo) yebutt welding flange catalytic cracking reactors, mbiya zvikamu zvehydrogenation reactors, fetiraiza Chivharo chepamusoro, chivharo chepasi, uye musoro unodiwa kune midziyo ndeye forgings.

Mhete dzemhete dzemugodhi: Zvinoenderana nehuremu hwemidziyo, chikamu chefogi mumidziyo yemugodhi i12-24%. Midziyo yemugodhi inosanganisira: midziyo yekuchera migodhi, yekusimudza, yekupwanya, yekukuya, yekugezesa, uye sintering.

Nuclear power ring forgings: Simba renyukireya rakakamurwa kuita marudzi maviri: madhirigi emvura anodzvanyirirwa uye anofashaira emvura. Iwo makuru mafogiji ezvidyarwa zvemagetsi enyukireya anogona kukamurwa kuita mapoka makuru maviri: magomba ekumanikidza uye zvikamu zvemukati. The pressure shell inosanganisira: cylinder flange, chikamu chemhino, muromo, silinda yepamusoro, silinda yepasi, cylinder transition chikamu, bhaudhi, nezvimwe zvakadaro. Izvo zvikamu zvemukati zvemurwi zvinoshandiswa pasi pemamiriro ezvinhu akaoma akadai sekushisa kwepamusoro, kukwirira kwepamusoro, simba reutron irradiation, boric acid water corrosion, scouring uye hydraulic vibration, saka 18-8 austenitic stainless steel inoshandiswa.

Thermal power ring forgings: Kune mana makiyi ekugadzira mumidziyo yekugadzira magetsi emagetsi, zvinoti rotor uye kuchengetedza mhete yejenareta returbine, uye impeller uye steam turbine rotor mumhepo turbine.

Hydroelectric ring forgings: Yakakosha forgings muhydropower station midziyo inosanganisira turbine shafts, hydro-jenareta shafts, magirazi mahwendefa, thrust misoro, nezvimwe.

Zvinowanzoshandiswa zvinhu: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 |42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30NiCrMo12 |22NiCrMoV|EN 1.4201

Mhete yeFOG

Mhete yakakura yekunyepedzera inosvika kuOD 5000mm x ID 4500x Thk 300mm chikamu. Kugadzira kushivirira kwemhete kazhinji -0/+3mm kusvika +10mm zvinoenderana nehukuru.

Metals ese ane hunyanzvi hwekugadzira kugadzira mhete yefodya kubva kune anotevera alloy marudzi:

● Alloy simbi

●Kabhoni simbi

●Simbi isina tsvina

FORGED RING MATANHU

Material

MAX DIAMETER

MAX WIGHT

Carbon, Alloy Steel

5000mm

15000 kgs

Simbi isina ngura

5000mm

10000 kgs

Shanxi DongHuang Mhepo Simba Flange Manufacturing Co., LTD. , se ISO yakanyoreswa yakanyoreswa mugadziri wefogi, inovimbisa kuti mafogi uye/kana mabhawa ane homogenous mumhando uye haana anomalies izvo zvinokanganisa ma mechanika zvivakwa kana machining midziyo yechinhu.

Nyaya:

Steel Giredhi1.4201

Kemikari inoumbwa% yesimbi 1.4201

| C | Si | Mn | P | S | Cr |

| Min. 0.15 | - | - | - | - | 12.0 |

| Max. - | 1 | 1 | 0.040 | 0.03 | 14.0 |

| Giredhi | UNS Nha | Old British BS | Euronorm En | Swedish Hapana Zita | Japanese SS JIS | Chinese GB/T 1220 |

| 420 | S42000 | 420S37 | 56C 1.4021 X20Cr13 | 2303 | SUS 420J1 | 2Cr13 |

Simbi giredhi 1.4021 (inonziwo ASTM 420 uye SS2303) isimba rakasimba remartensitic Stainless simbi ine yakanaka ngura zvinhu. Simbi inogoneka uye inokodzera kugadzirwa kweruzivo nekuramba kwakanaka kune semuenzaniso mvura yemhepo, mvura yakachena, mamwe alkaline mhinduro uye mamwe makemikari ane hunyoro. Haifanirwe kushandiswa mumakungwa kana munzvimbo yechloride. Iyo simbi ine magineti uye mune inodzimwa uye yakadzikama mamiriro.

Applications

Dzimwe dzakajairika nzvimbo dzekushandisa dzeEN 1.4021

Pombi- uye mavharuvhu zvikamu, Shafting, Spindels, Piston tsvimbo, Fittings, Stirrers, Bolts, Nuts EN 1.4021 Forged mhete, Stainless Simbi forgings yeSlewing mhete.

Saizi: φ840 xφ690x H405mm

Kugadzira (Kupisa Basa) Kudzidzira, Kupisa Kurapa Maitiro

| Annealing | 800-900 ℃ |

| Tempering | 600-750 ℃ |

| Quenching | 920-980℃ |

| Rm-Kusimba simba (MPa) (A) | 727 |

| Rp0.20.2% chiratidzo chesimba (MPa) (A) | 526 |

| A- Min. kureba pakutyoka (%) (A) | 26 |

| Z -Kuderedzwa kwechikamu chemuchinjiko pane kuputsika (%) (A) | 26 |

| Brinell kuoma (HBW): (+A) | 200 |

RUDZIDZO RWEKUWEDZERA

KUMBIRA KUPIWA NHASI

KANA KUFANA: 86-21-52859349