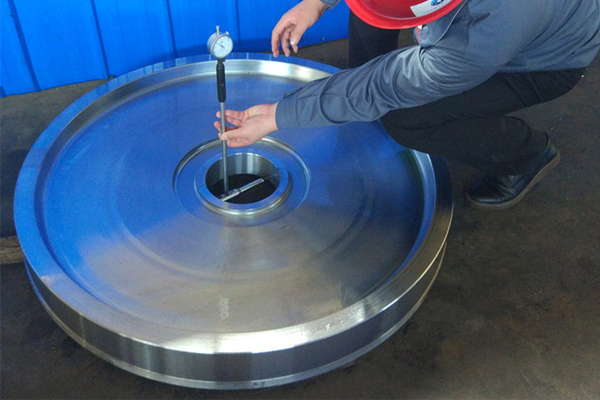

Kuongororwa kwemhando yechitarisiko kunowanzo kuve kusingaparadze ongororo, kazhinji neziso rakashama kana yakaderera yekukudza girazi yekuongorora, kana zvichidikanwa, zvakare shandisa isiri-inoparadza yekuongorora nzira.

Nzira dzekuongorora dzemukati wemhando yezvinorema forgingsinogona kupfupikiswa se: macroscopic sangano rekuongorora, microscopic sangano rekuongorora, mechaniki zvivakwa zvekuongorora, makemikari kuumbwa kwekuongorora uye kusaparadza kuyedza.

Macroscopic microstructure test imhando yebvunzo yekutarisa uye yekuongorora yakaderera-simba microstructure maitiro eforgingnegirazi rinokudza kana kuti repasi-simba. Iyo inowanzoshandiswa nzira dze macroscopic chimiro chekuongorora cheforgingsinzira yakaderera-simba corrosion (inosanganisira thermal corrosion, cold corrosion uye electrolytic corrosion method), bvunzo dzekutyoka uye nzira yekudhinda sarufa.

Microstructure inspection mutemo ndeye kushandisa chiedza microscope kutarisa microstructure yeforgingszvezvinhu zvakasiyana-siyana. Zvinhu zvekuongorora zvinowanzo sanganisira saizi yezviyo, kana saizi yezviyo pane tembiricha yakatarwa, kureva saizi chaiyo yezviyo, isiri-simbi inosanganisirwa, microstructure senge decarburization layer, eutectic carbide inhomogeneity, overheat, overburn uye zvimwe zvinodiwa microstructure, nezvimwe.

Mechanical zvivakwa uye process performance inspection ndiyo yanga iri yekupedzisira kupisa kurapwa kweforgingsuye zvimedu zvekuyedza zvakagadziridzwa kuita sampuli yakatarwa mushure mekushandiswa kwemushini wekutemesa wekuyedza, mhedzisiro yekuyedza muchina, endurance yekuyedza muchina, kuneta kuyedza muchina, hardness tester uye zvimwe zviridzwa kuona ma mechanic properties uye kugadzirisa maitiro ekuita.

Kemikari kuumbwa kuyedzwa kunowanzo kushandiswa kwekuongorora kwemakemikari kana spectral ongororo yekugadzira zvikamu zvekuongorora uye kuyedza, nekuvandudzwa kwesainzi uye tekinoroji, zvese zviri zviviri kuongororwa kwemakemikari uye spectral ongororo yekuongorora kwayo nzira dzakafambira mberi. Kuongorora kwekuona, ikozvino haisi kungoshandisa nzira ye spectral uye nzira ye spectroscopic yekuita chikamu chekuongorora, kubuda kwe photoelectric spectrometer kwete kungokurumidza kuongorora, asiwo inovandudza zvikuru kurongeka, uye kubuda kweplasma photoelectric spectrometer yakavandudza zvikuru kuongorora kurongeka, kuongorora kwayo kunyatsojeka kunogona kusvika 10 nzira inokuvadza inogona kusvika 10. Pb, As, Sn, Sb, Bi mune superalloy forgings.

Zvakataurwa pamusoro apa, iyo nzira yekuyedza, macroscopic sangano, uye kuumbwa uye microstructure bvunzo kana kuita kana nzira, zvese ndezvenzira inoparadza yekuyedza, kune mamwe anorema ekugadzira nzira dzekuparadza haakwanise kunyatsoenderana nezvinodiwa zvekuongororwa kwemhando, kune rimwe divi, izvi imhaka yekuti hausi hupfumi, kune rumwe rutivi ndeyekunyanya kudzivirira kudivi rimwe rekuparadza kuyedza. Iko kuvandudzwa kweNDT tekinoroji inopa yakawedzera yepamusoro uye nzira dzakakwana dzeforgingkuongororwa kwehutano.

Nondestructive kuyedza nzira dzekugadzira yemhando yekuongorora dzinowanzo: magineti poda yekuongorora nzira, yekupinda yekuongorora nzira, eddy yazvino yekuongorora nzira, ultrasonic yekuongorora nzira.

Magnetic particle yekuongorora nzira inoshandiswa zvakanyanya kuongorora pamusoro kana padhuze nekukanganisa kwe ferromagnetic simbi kana alloy.forgings, zvakadai sekutsemuka, makwinya, mavara machena, asiri-metallic inclusions, delamination, kupeta, carbide kana ferritic bands, etc. Iyi nzira inokodzera chete kuongororwa kweferromagnetic.forgings, asi kwete yekugadzira yakagadzirwa nesimbi austenitic.

Penetrant yekuongorora nzira haigone kungotarisa iyo magineti yekugadzira zvinhu, asi zvakare yekutarisa kuremara kwepasi kweiyo isiri-ferromagnetic zvinhu.forgings, zvakadai sekutsemuka, kusununguka, kupeta, etc. Kazhinji, inongoshandiswa kutarisa kukanganisa kwepamusoro kwe-non-ferromagnetic material forgings, uye haigoni kuwana kukanganisa kwakavanzika pasi pepamusoro. Eddy yazvino yekuyedza inoshandiswa kutarisa pamusoro kana padyo nepamusoro pehurema hwezvinhu zvinoitisa.

Ultrasonic inspection method inoshandiswa kutarisa kukanganisa kwemukati kwekugadzira zvakadai se shrinkage cavity, white spot, core crack, slag inclusion, etc. Kunyange zvazvo nzira iyi iri nyore, inokurumidza uye ine hupfumi, zvakaoma kunyatsoona mamiriro ekuremara.

Nguva yekutumira: Nov-17-2021