Forged Bars

Vhura Die Forgings Mugadziri muChina

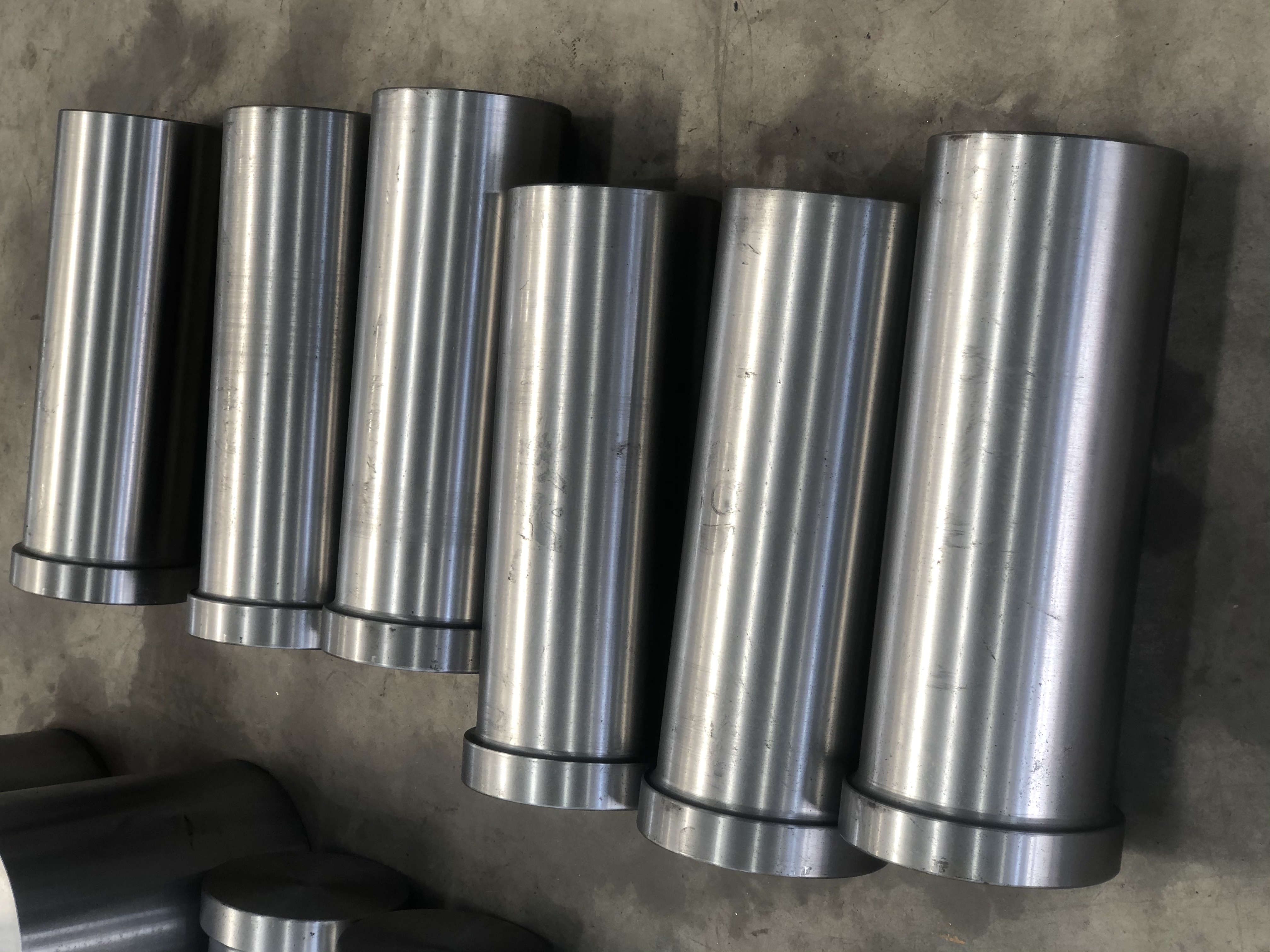

Forged Bars

Zvinowanzoshandiswa zvinhu: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 |42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30NiCrMo12 |22NiCrMoV12

MABHA AKAMAKA MAUMBO

Round bars, Square bars, Flat bars uye Hex mabara. Metals ese ane hunyanzvi hwekuumba kugadzira mabara kubva kune anotevera alloy marudzi:

● Alloy simbi

● Carbon steel

● Simbi isina tsvina

ZVINOGONESWA BHARA

ALLOY

MAX WIDTH

MAX WIGHT

Carbon, Alloy

1500mm

26000 kgs

Simbi isina ngura

800mm

20000 kgs

ZVINOGONESWA BHARA

Hurefu hwehurefu hwefoged round bars uye hex bars i5000 mm, nehuremu hwepamusoro hwe20000 kgs.

Hurefu nehupamhi hwemabhawa akafuratira uye masikweya mabhawa i1500mm, nehuremu hwepamusoro hwe26000 kgs.

A bhawa reforged kana bhara rakakungurutswainogadzirwa nekutora ingot uyeforgingiyo kusvika pakukura ne, kazhinji, maviri anopikisana flat anofa. Simbi dzakagadzirwa dzinoita kunge dzakasimba, dzakaoma uye dzakasimba kupfuura mafomu akakandwa kana zvikamu zvemuchina. Iwe unogona kuwana yakagadzirwa zviyo chimiro mukati mese zvikamu zve forgings, kuwedzera zvikamu ablitity kutsungirira warping uye kupfeka.

Shanxi DongHuang Wind Power Flange Manufacturing Co., LTD., seISO yakanyoreswa yakanyoreswa mugadziri wekugadzira, inovimbisa kuti forgings uye/kana mabara ane homogenous mumhando uye haana anomalies izvo zvinokanganisa kumagetsi zvivakwa kana machining midziyo yechinhu.

Nyaya:

Steel GiredhiEN 1.4923 X22CrMoV12-1

ChimiroMartensitic

| Kemikari yakagadzirwa% yesimbi X22CrMoV12-1 (1.4923): EN 10302-2008 | ||||||||

| C | Si | Mn | Ni | P | S | Cr | Mo | V |

| 0.18 - 0.24 | hukuru 0.5 | 0.4 - 0.9 | 0.3 - 0.8 | hukuru 0.025 | hukuru 0.015 | 11 - 12.5 | 0.8 - 1.2 | 0.25 - 0.35 |

Applications

Powerplant, Machine engineering, Power generation.

Zvikamu zvepombi-mitsetse, steam boilers uye turbines.

Delivery form

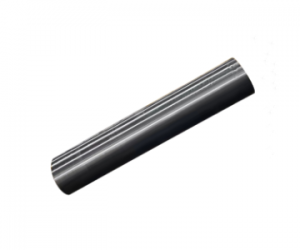

Round bar, Rolled Forgings Rings, Bored roundbars, X22CrMoV12-1 Forged bar

Saizi: φ58x 536L mm.

Kugadzira (Kupisa Basa) Dzidzira

Zvishandiso zvinotakurwa muchoto uye zvinopisa. Kana tembiricha yasvika 1100 ℃, simbi inogadzirwa. Rinoreva chero mechanical process inoumba metal ulilizing imwe kana kupfuura inofa, eg yakavhurika/yakavharwa kufa forging, extrusion, rolling, etc. Panguva iyi, tembiricha yesimbi inodonha. Kana yadzikira kusvika 850 ℃, simbi inozopiswa zvakare. Wobva wadzokorora basa rinopisa pane iyo tembiricha yakakwira (1100 ℃). Iyo diki reshiyo yekupisa basa reshiyo kubva ingot kusvika billet ndeye 3 kusvika 1.

Kupisa Kurapa Maitiro

Rodha iyo preheat kubata machining zvinhu mukupisa kurapwa furance. Kupisa kusvika ku900 ℃. Bata pamhepo kwe6 maawa 5 maminitsi. Mafuta anodzima uye hasha pa640 ℃. Ipapo Mhepo-inotonhorera.

Mechanical zvimiro zveX22CrMoV12-1 forged bar (1.4923).

| Rm-Kusimba simba (MPa) (+QT) | 890 |

| Rp0.20.2% chiratidzo chesimba (MPa) (+QT) | 769 |

| KV-Impact simba (J) (+QT) | -60° 139 |

| A - Min. kureba pakutyoka (%) (+QT) | 21 |

| Brinell kuoma (HBW): (+A) | 298 |

Chero mamakisi emidziyo, kunze kwekutaurwa pamusoro apa, anogona kugadzirwa sezvinodiwa nemutengi.