Akụkọ ụlọ ọrụ

-

Kedu ihe mmetụta nke ịhịa aka n'ahụ siri ike na usoro ịgha mkpụrụ?

Esemokwu dị n'ichepụta ihe bụ esemokwu n'etiti ọla abụọ nke dị iche iche mejupụtara na akụrụngwa (alloys), n'etiti igwe dị nro (workpiece) na metal siri ike (anwụ anwụ). N'ihe banyere enweghị mmanu mmanu, bụ kọntaktị esemokwu nke abụọ ụdị metal elu oxide film; N'okpuru ọnọdụ mmanu mmanu, conta...GỤKWUO -

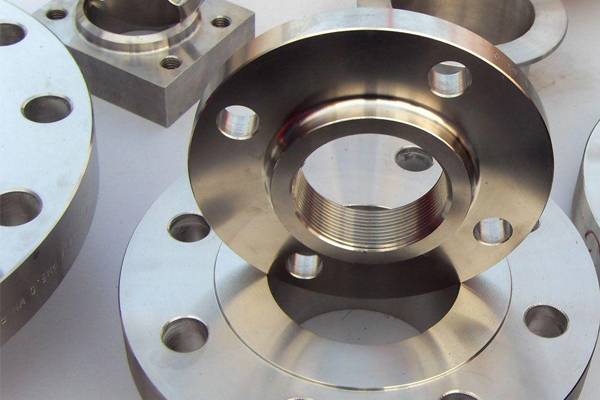

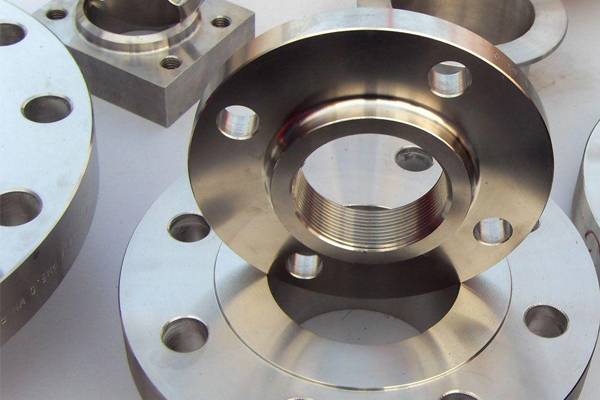

Nhazi zuru oke nke flange ndị a na-ejikarị na China

1. Dị ka ọkọlọtọ nke n'ibu ụlọ ọrụ, flange ụdị bụ: efere ụdị flat-welded flange, butt-welded flange, integral flange, butt-welded mgbanaka-efere ụdị rụrụ aka uwe flange, flat-welded mgbanaka-efere ụdị rụrụ aka uwe flange, flanged mgbanaka-efere ụdị rụrụ aka uwe flange, flange cover. 2...GỤKWUO -

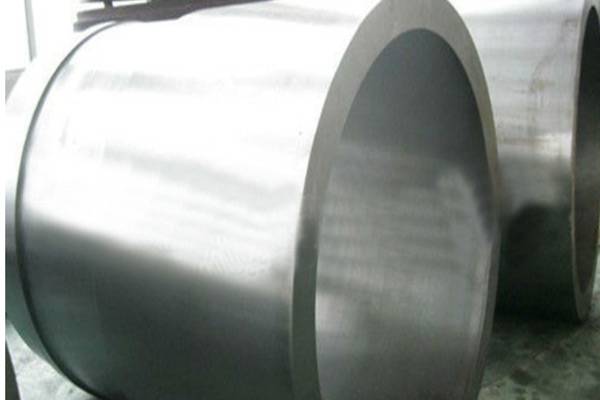

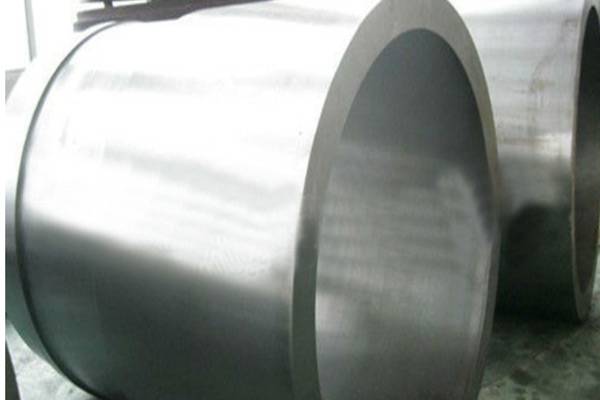

Kedu ụdị osisi forgings na-emezu ihe achọrọ?

Axial forging bụ ụdị obosara ngwa nke forgings, dị ka axial gbakwunyere nwere ezi processability, m ọ bụla porosity na omume, ọ dịghị ndị ọzọ flaws, otú ọ bụghị naanị nwere ọdịdị dị mma, na ezi, ebe a bụ otú ewebata gị kwekọọ na chọrọ nke axial forgings na-ewu ewu. Ndị mbụ...GỤKWUO -

Usoro akara nke hydraulic cylinder forging

Ihe mere e ji dị mkpa ka a mechie forgings hydraulic cylinder bụ n'ihi ịdị adị nke ntanye dị n'ime na nkwụsị nke mpụga. Mgbe enwere ntapu dị n'ime na mpụta mpụta na hydraulic cylinder, ọ ga-eduga na olu nke oghere hydraulic cylinder na arụmọrụ wi...GỤKWUO -

Kedu teknụzụ ịgha ụgha nke ụlọ ọrụ flange nwere?

Ụlọ ọrụ Flange bụ ụlọ ọrụ mmepụta ihe na-emepụta flanges. Flanges bụ akụkụ jikọtara n'etiti ọkpọkọ, nke a na-eji maka njikọ n'etiti ọkpọkọ ọkpọkọ. Ọ dịkwa uru maka flange na ntinye na ntinye nke akụrụngwa maka njikọ n'etiti ngwaọrụ abụọ. Teknụzụ mmepụta ...GỤKWUO -

Kedu ka esi emepụta forgings igwe anaghị agba nchara?

Nkenkenke nke siri ike ma ọ bụ igwe anaghị agba nchara forgings dị elu. Ngwa nke teknụzụ dị elu na akụrụngwa nwere ike nweta obere ma ọ bụ enweghị ịkpụ. Ihe ndị a na-eji ígwè eme ihe na-emepụta kwesịrị inwe ezigbo plasticity, nke mere na n'okpuru ọrụ nke ike mpụga, enwere ike ịmepụta nrụrụ plastik site na ...GỤKWUO -

Ụkpụrụ akara na njirimara nke flange

Ichichi flanges gbadoro anya na-abụkarị okwu na-ekpo ọkụ metụtara ọnụ ahịa mmepụta ma ọ bụ uru akụ na ụba nke ụlọ ọrụ. Otú ọ dị, isi mwepu nke imewe flanges ewepụghị-welded bụ na ha anaghị echebe. Nke a bụ ntụpọ imewe: njikọ ahụ dị ike, yana ibu oge, dị ka ...GỤKWUO -

Kedu ihe ekwesịrị ịdeba ama na nyocha nke ịnwụ anwụ tupu ọgwụgwọ okpomọkụ?

The nnyocha tupu ngwọta okpomọkụ ọgwụgwọ bụ tupu nnyocha usoro ịlele okokụre ngwaahịa si n'elu àgwà na akụkụ dị ka teknuzu ọnọdụ, anwụ forging ịbịaru na usoro kaadị mgbe forging akpụ usoro okokụre. Nyocha a kapịrị ọnụ kwesịrị ịkwụ ụgwọ ...GỤKWUO -

Otu esi achọta ihe isi ike nhazi nke flange igwe anaghị agba nchara

Nke mbụ, tupu ịhọrọ ihe ọkụkụ ahụ, lelee ihe isi ike dị na nhazi flange igwe anaghị agba nchara. Chọpụta na ihe isi ike nwere ike ịbụ nke ziri ezi, dị ngwa ngwa ịchọta ojiji nke akuakuzinwo. Kedu ihe isi ike na nhazi flange igwe anaghị agba nchara? Mma nnyapade: igwe anaghị agba nchara pr ...GỤKWUO -

Kedu usoro a na-esi akpụ akpụ?

1. Isothermal forging bụ idobe okpomọkụ nke billet na-adịgide adịgide n'oge usoro nhazi dum. A na-eji forging Isothermal mee ihe iji nweta uru nke nnukwu plasticity nke ụfọdụ ọla na okpomọkụ mgbe niile ma ọ bụ nweta ihe owuwu na ihe onwunwe. Isothermal forging chọrọ ebu ...GỤKWUO -

Isi mwepu nke mmiri dị ka a quenching jụrụ usoro maka forgings?

1) na austenite isothermal mgbanwe eserese nke a na-ahụkarị ebe, ya bụ, banyere 500-600 ℃, mmiri na uzuoku film ogbo, jụrụ ọnụego adịghị ngwa ngwa zuru ezu, na-emekarị ka ọ na-ekwekọghị ekwekọ obi jụrụ na ezughi oke jụrụ forgings na guzobe nke "dị nro" .Na martensite transf ...GỤKWUO -

Kedu ụdị njikọ bolt na-eji flange igwe anaghị agba nchara?

Ndị ahịa na-ajụkarị: njikọ flange igwe anaghị agba nchara ma ịhọrọ bolts igwe anaghị agba nchara? Ugbu a, m ga-ede ihe m mụtara ịkọrọ gị: Ihe enweghị ihe jikọrọ ya na ihe nke flange bolts, dị ka European usoro HG20613-97 "steel anwụrụ flange na fasteners (na ...GỤKWUO