Nhọrọ buru ibu maka Ansi B16.5 - diski echedoro - DHDZ

Nhọrọ buru ibu maka Ansi B16.5 - diski echedoro - Nkọwa DHDZ:

Mepee onye nrụpụta Forgings na China

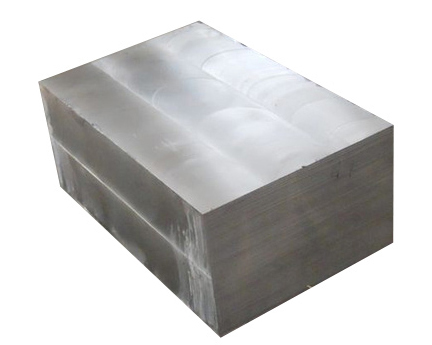

Diski adịgboroja

Gear oghere, flanges, okpu ngwụcha, ihe mejupụtara arịa nrụgide, ihe mejupụtara valvụ, ahụ valvụ, na ngwa ọkpọkọ. Disk adịgboroja dị elu karịa diski ebipụ site na efere ma ọ bụ mmanya n'ihi n'akụkụ niile nke diski ahụ nwere mbelata mbelata n'ihu na-emezi usoro ọka ọka na imeziwanye ihe mmetụta ike na ndụ ike ọgwụgwụ. Ọzọkwa esorowo diski ike forged na ọka eruba ka kasị mma dabara ikpeazụ akụkụ ngwa dị ka radial ma ọ bụ tangential ọka eruba nke ga-enyere aka melite n'ibu Njirimara nke ihe onwunwe.

Ihe eji eme ihe: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 | 42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30NiCrMo12 | 22NiCrMoV

Eserese diski

Nnukwu akpụ akpụ akparala ngọngọ ruo 1500mm x 1500mm ngalaba nwere ogologo mgbanwe.

Gbochie nnabata nnabata na-abụkarị -0/+ 3mm ruo +10mm dabere na nha.

● Metals niile nwere ikike ịgha mkpụrụ iji mepụta ihe mgbochi sitere na ụdị alloy ndị a:

● Alloy ígwè

● Carbon ígwè

● Igwe anaghị agba nchara

IKE DỊSỊS EKWESỊRỊ

Ihe onwunwe

MAX DIAMETER

Ibu ibu

Carbon, Alloy Steel

3500mm

20000 kgs

Igwe anaghị agba nchara

3500mm

18000 n'arọ

Shanxi DongHuang Wind Power Flange Manufacturing Co., LTD. , dị ka ISO debanyere aha onye na-emepụta ihe na-emepụta ihe, na-ekwe nkwa na forgings na/ma ọ bụ ụlọ mmanya na-emekọ ihe n'ịdị mma na enweghị ihe ọ bụla nke na-emerụ ihe eji arụ ọrụ ma ọ bụ nhazi nke ihe onwunwe.

Ikpe:

Steel ọkwa SA 266 Gr 2

| Ngwakọta kemịkalụ% nke ígwè SA 266 Gr 2 | ||||

| C | Si | Mn | P | S |

| Kachasị 0.3 | 0.15 - 0.35 | 0.8-1.35 | Ọnụahịa kasị elu nke 0.025 | kacha elu 0.015 |

Ngwa

Gear oghere, flanges, okpu ngwụcha, ihe mejupụtara arịa nrụgide, ihe valvụ, ahụ valvụ, na ngwa ọkpọkọ.

Ụdị nnyefe

Diski adịgboroja, diski akpara akpa

SA 266 Gr 4 diski akpara akpa, igwe carbon ígwè maka arịa nrụgide

Size: φ1300 x thk 180mm

Ịmepụta (Ọrụ Na-ekpo ọkụ) Omume, Usoro ọgwụgwọ okpomọkụ

| Na-akpụ akpụ | 1093-1205 ℃ |

| Na-ewe iwe | 778-843 ℃ ọkụ dị jụụ |

| Iwe iwe | 399-649 ℃ |

| Na-emezigharị | 871-898 ℃ ikuku dị jụụ |

| Mee ka o doo anya | 815-843 ℃ emenyụ mmiri |

| Mbelata nchekasị | 552-663 ℃ |

| Na-emenyụ | 552-663 ℃ |

| Rm - Ike ntakiri (MPa) (N) | 530 |

| RP0.2 0.2% ike ihe akaebe (MPa) (N) | 320 |

| A - Min. elongation na mgbaji (%) (N) | 31 |

| Z - Mbelata na akụkụ obe na mgbaji (%) (N) | 52 |

| hardness brinell (HBW): | 167 |

OZI MGBAKWUNYE

RỊỌRỌ OKWU TAA

Ma ọ bụ Kpọọ: 86-21-52859349

Foto nkọwa ngwaahịa:

Ntuziaka ngwaahịa emetụtara:

Iji a ngụkọta sayensị ezi àgwà management usoro, elu àgwà na magburu onwe okwukwe, anyị na-enweta oké aha na occupied a ubi maka Massive Nhọrọ maka Ansi B16.5 - Forged Discs – DHDZ , The ngwaahịa ga-enye n'ụwa nile, dị ka: Peru, Singapore, Iran, The credibility bụ ihe kacha mkpa, na ọrụ bụ vitality. Anyị na-ekwe nkwa na anyị nwere ugbu a ikike ịnye ihe dị mma na ihe ezi uche dị na ya maka ndị ahịa. N'ebe anyị nọ, a na-ekwe nkwa nchekwa gị.

Ụlọ ọrụ ahụ nwere akụrụngwa bara ụba, igwe dị elu, ndị ọrụ nwere ahụmahụ na ọrụ magburu onwe ya, na-atụ anya na ị na-emeziwanye ma na-emeziwanye ngwaahịa na ọrụ gị, na-achọ gị mma!