Nnukwu mgbanaka ọkara-mgbanaka

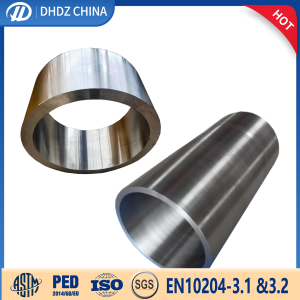

Nkọwa ngwaahịa:

Ebe Mmalite: Shanxi

Aha ika: DHDZ

Asambodo: ASME, JIS, DIN, GB, BS, EN, AS, SABS, ASTM A370, API 6B, API 6C

Ọnụ ahịa kacha nta: 1 ibe

Oke oke: Max OD4000mm

Ngwungwu njem: Plywood Case

Nkwupụta ule: MTC, HT, UT, MPT, mkpesa akụkụ, Nlele anya, EN10204-3.1, EN10204-3.2

Ahịa: Negotiable

Ike mmepụta: 100 PCS / ọnwa

| Ihe eji eme ihe | C | Mn | P | S | SI | Cr | NI | Mo | Cu | N |

| A182 F51 | ≤ 0.030 | 2.0 | ≤ 0.030 | ≤ 0.020 | <0.80 | 21-23 | 4.5-6.5 | 2.50-3.50 | / | 0.20-0.24 |

| A105 | 0.19-0.23 | 0.9-1.05 | 0.035 | ≤ 0.030 | 0.15-0.3 | ≤ 0.1 | ≤ 0.4 | ≤ 0.12 | ≤ 0.4 | / |

| LF2 | 0.19-0.23 | 0.9-1.05 | 0.035 | ≤ 0.030 | 0.15-0.3 | ≤ 0.1 | ≤ 0.4 | ≤ 0.12 | ≤ 0.4 | / |

| 42CrMo4 | 0.43 | 1.0 | <0.030 | <0.040 | <0.35 | 0.8-1.1 | <0.030 | 0.15-0.25 | / | / |

| 35NiCrMoV12-5 | 0.30-0.40 | 0.4-0.7 | ≤ 0.015 | ≤ 0.015 | ≤ 0.35 | 1.0-1.4 | 2.5-3.5 | 0.35-0.65 | / | / |

| 20MnMo | 0.17-0.23 | 1.1-1.4 | ≤0.025 | ≤0.015 | 0.17-0.37 | ≤0.030 | ≤0.030 | 0.20-0.35 | / | / |

| Ihe eji arụ ọrụ | Dia.(mm) | TS/Rm (Mpa) | YS/Rp0.2 (Mpa) | EL/A5 (%) | RA/Z (%) | Ọkwa | Mmetụta ike | HBW |

| A182 F51 | / | ≥620 | ≥450 | ≥25 | 45 | V | ≥45J | / |

| A105 | / | ≥485 | ≥250 | ≥22 | ≥30 | V | / | 143-187 |

| LF2 | / | 485-655 | ≥250 | ≥22 | ≥30 | V | ≥27J (-29℃) | 143-187 |

| 42CrMo4 | Ф10 | 1080 | 930 | 25 | 45 | V | ≥25J (-60℃) | <217 |

| 35NiCrMoV12-5 | Ф12.5 | ≥1100 | ≥850 | ≥8.0 | / | V | / | / |

| 20MnMo | Ф10 | ≥605 | ≥475 | ≥25 | / | V | ≥180 | / |

Usoro mmepụta:

Akpụkpọ anụ nchara nchara nchara n'ime ụlọ nkwakọba ihe (nnwale ọdịnaya kemịkalụ) → Ịcha → Heat (Nnwale okpomọkụ) → Ọgwụgwọ ọkụ mgbe ịmechara (nnwale ọkụ ọkụ) Wepu ọkụ (nyocha oghere) → Machining → Inspection(UT) ,MT, Visal diamention, hardness)→ QT→ Nyocha (UT, n'ibu Njirimara, isi ike, ọka size) → Mechaa igwe → Nyocha (akụkụ) → mbukota na akara (stampụ ígwè, akara) → Mbupu nchekwa

Uru:

Njirimara igwe dị mma,

Nkwenye akụkụ dị oke oke,

Jikwaa usoro mmepụta nke ọma,

Ngwá ọrụ nrụpụta dị elu na ngwaọrụ nyocha,

Ọkachamara teknụzụ mara mma,

Mepụta akụkụ dị iche iche dabere na ihe ndị ahịa chọrọ,

Lezienụ anya na nchekwa ngwugwu,

Ogo zuru oke ọrụ.

Ụlọ ọrụ ngwa:

Ụlọ ọrụ Petrochemical, ụlọ ọrụ ndị agha, modul ụlọ ọrụ, ụlọ ọrụ ụgbọ ala, ikpo okwu dị n'ụsọ mmiri, nhazi akụkụ, ụlọ ọrụ ụgbọ ala, ngwaọrụ ahụike, wdg.