Ọnụ ahịa ụlọ ọrụ n'akụkụ mpịakọta mgbanaka ejirila igwe arụrụ arụ - Cylinders akpara akpa - DHDZ

Akụkụ Mpịakọta ọnụ ụlọ mmepụta ihe mgbanaka igwe eji arụ ọrụ - Cylinder akpara akpa - Nkọwa DHDZ:

Mepee onye nrụpụta Forgings na China

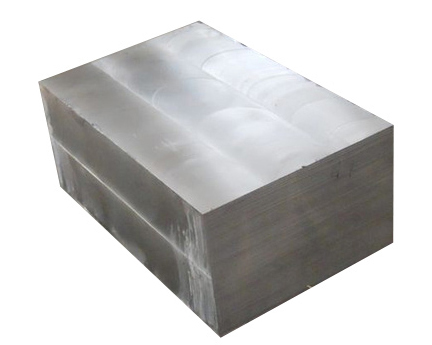

Cylinder kpụrụ akpụ

| Oke. OD | Oke. Ogologo | Oke. Ibu |

| 4000mm | 10000mm | Tọn 30 |

DHDZ na-arụpụta cylinders oghere na-enweghị nkebi, mgbidi oghere dị arọ na aka n'ụdị nhazi ahaziri iche dị ka ihe ndị ahịa chọrọ. Oghere akpara nke ọma na-enweghị nkebi dị mma maka ngwa mgbakasị ahụ na gburugburu ebe siri ike n'ihi ịdịte aka ha, ike na nguzogide corrosion. Enwere ike imepụta oghere ọ bụghị naanị n'ụdị cylindrical kwụ ọtọ, mana enwere ọdịiche na-akparaghị ókè nke OD na ID, gụnyere taper.

Na mgbakwunye, DHDZ na-enye nhazi niile dị n'okpuru ala gụnyere ọgwụgwọ okpomọkụ, igwe na igwe na nnwale na-adịghị emebi emebi, mgbe a rịọrọ ya. Kpọtụrụ anyị taa na nkọwapụta gị kpọmkwem, ndị otu anyị ga-arụ ọrụ na gị iji nweta ike anyị iji belata ihe mkpofu ihe na ibelata usoro adịghị arụ ọrụ.

Ihe eji eme ihe: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 |42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30NiCrMo12 | 22NiCrMoV| EN 1.4201 | 42CrMo4

Shanxi DongHuang Wind Power Flange Manufacturing Co., LTD., Dị ka onye debanyere aha nke ISO debanyere aha arụrụ arụ ọrụ, na-ekwe nkwa na forgings na / ma ọ bụ ụlọ mmanya na-adakọ ọnụ na ịdị mma yana enweghị ihe ọ bụla nke na-emebi akụrụngwa akụrụngwa ma ọ bụ ihe eji arụ ọrụ.

Ikpe: Steel Grade AISI 4130 Alloy Steel (UNS G41300)

Njirimara anụ ahụ

| Njirimara | Metric | Ihe onwunwe |

| Njupụta | 7.85 g/cm3 | 0.284 lb/n'ime³ |

| Ebe mgbaze | 1432°C | 2610°F |

Nkọwa na ihe ndị dabara adaba AISI 4130 Alloy steel

| AISI 4130 | C | Mn | Si | P | S | Cr | Mo | Ni | Cu | Mo |

| 0.280 - 0.330 | 0.40 - 0.60 | 0.15-0.30 | 0.030 kacha | 0.040 kacha | 0.80-1.10 | 0.15-0.25 | 0.25 max | 0.35 max | 0.15-0.25 |

| ASTM A29/A29M | DIN17350 | JIS G4404 | GB/T 1229 | ISO 683/18 |

| AISI 4130/G41300 | 1.7218/25CrMo4 | SMN 420 | 25CrMo4 | 25CrMo4 |

Ngwa

Ụfọdụ mpaghara ngwa a na-ahụkarị maka AISI 4130:

Ụlọ ọrụ mmanụ na gas - dị ka ozu valvụ arụrụ arụ na nfuli

Ụgbọ elu azụmahịa, igwe ụgbọ elu na-ebuli elu

Ụgbọ elu ndị agha

Ụgbọala

Ngwa igwe

Ngwá ọrụ hydraulic

Ọsọ ụgbọ ala

Igwe ikuku

Ụlọ ọrụ ugbo na nchekwa wdg.

AISI 4130 Cylinder Forged, Alloy Alloy Steel forgings maka ụlọ ọrụ mmanụ na gas.

nha: φ774.8 0xφ317.0XH825.5mm

Ịmepụta na ọgwụgwọ okpomọkụ

Machinability - AISI 4130 ígwè nwere ike ịme ngwa ngwa site na iji usoro omenala. Otú ọ dị, machining na-esi ike mgbe ike nke ígwè na-abawanye.

Enwere ike ịme nhazi nke AISI 4130 nchara na ọnọdụ annealed.

● Welding nke AISI 4130 ígwè nwere ike ịrụ ọrụ niile nke azụmahịa.

● Ọgwụgwọ okpomọkụ - AISI 4130 ígwè na-ekpo ọkụ na 871 ° C (1600 ° F) wee menyụọ na mmanụ. A na-agwọkarị ígwè a okpomọkụ na okpomọkụ sitere na 899 ruo 927°C (1650 ruo 1700°F).

● A na-arụ ọrụ ígwè AISI 4130 na 954 ruo 1204 ° C (1750 ruo 2200 ° F).

● Na-arụ ọrụ ọkụ nke AISI 4130 ígwè nwere ike ime na 816 ruo 1093 ° C (1500 ruo 2000 ° F).

● AISI 4130 ígwè nwere ike ịrụ ọrụ oyi site na iji usoro omenala.

● AISI 4130 ígwè nwere ike imechi na 843°C (1550°F) na-esote ikuku jụrụ na 482°C (900°F).

● Enwere ike ịme ọkụ nke AISI 4130 ígwè na 399 ruo 566 ° C (750 ruo 1050 ° F), dabere na ọkwa ike achọrọ.

● Ịkwado nke AISI 4130 ígwè nwere ike ime na-arụ ọrụ oyi ma ọ bụ ọgwụgwọ okpomọkụ.

Ụfọdụ n'ime ngwa ndị bụ isi nke AISI 4130 alloy steel bụ n'elu igwe ụgbọ elu na tubing welded.

Ịmepụta (Ọrụ Na-ekpo ọkụ) Omume , Usoro ọgwụgwọ okpomọkụ

| Na-akpụ akpụ | 1093-1205 ℃ |

| Na-ewe iwe | 778-843 ℃ ọkụ dị jụụ |

| Iwe iwe | 399-649 ℃ |

| Na-emezigharị | 871-898 ℃ ikuku dị jụụ |

| Mee ka o doo anya | 815-843 ℃ emenyụ mmiri |

| Mbelata nchekasị | 552-663 ℃ |

| Na-emenyụ | 552-663 ℃ |

| Rm - ike tensile (MPa) (Q +T) | ≥930 |

| Rp0.2 0.2% ike ihe akaebe (MPa) (Q +T) | ≥785 |

| KV - ike mmetụta (J) (Q +T) | +20° |

| A - Min. elongation na mgbaji (%) (Q +T) | ≥12 |

| Z - Mbelata na mpaghara obe na mgbaji (%)(N+Q +T) | ≥50 |

| Isi ike brinell (HBW): (Q +T) | ≤229HB |

OZI MGBAKWUNYE

RỊỌRỌ OKWU TAA

Ma ọ bụ Kpọọ: 86-21-52859349

4130

4130

Ọhụrụ-4130-Alloy-Steel

Ọhụrụ-4130-Alloy-Steel

Foto nkọwa ngwaahịa:

Ntuziaka ngwaahịa emetụtara:

Our business sticks for the basic principle of "Quality might be the life with the firm, and track record will be the soul of it" n'ihi na Factory Price Side Roll Ring Forged Steel - Forged Cylinders – DHDZ , The ngwaahịa ga-ezitekwara n'ụwa nile, dị ka: Poland, Singapore, Angola, Na ya ọgaranya n'ichepụta ahụmahụ, elu-quality ngwaahịa, na zuru okè mgbe-saleed ụlọ ọrụ nwere ezigbo ụlọ ọrụ na-enweta ụlọ ọrụ pụrụ iche nke ụlọ ọrụ nwere nnukwu ụlọ ọrụ na-emepụta ihe pụrụ iche. series.Anyị ji ezi obi na-atụ anya guzobe azụmahịa mmekọrịta gị na-achụso otu uru.

Onye njikwa akaụntụ mere nkọwa zuru ezu banyere ngwaahịa ahụ, ka anyị wee nwee nghọta zuru oke banyere ngwaahịa ahụ, n'ikpeazụ anyị kpebiri imekọ ihe ọnụ.