Ọnụ ego n'ùkwù Plate Forging Tube Pipe - Ogwe akpara akpa - DHDZ

Ọnụ ego n'ùkwù Plate Forging Tube Pipe - Ogwe akpara akpa - Nkọwa DHDZ:

Mepee onye nrụpụta Forgings na China

Ogwe arụrụ arụ

Ihe eji eme ihe: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 | 42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30NiCrMo12 | 22NiCrMoV12

ỤSỊ OMU AKWỤKWỌ

Ogwe okirikiri, Ogwe Square, Ogwe Flat na Ogwe Hex. All Metals nwere ikike ịgha mkpụrụ osisi sitere na ụdị alloy ndị a:

● Alloy ígwè

● Carbon ígwè

● Igwe anaghị agba nchara

Ikike mmanya echekwabara

ALOY

Oke obosara

Ibu ibu

Carbon, Alloy

1500mm

26000 n'arọ

Igwe anaghị agba nchara

800mm

20000 kgs

Ikike mmanya echekwabara

Ogologo kachasị maka ogwe osisi gbara gburugburu na hex bụ 5000 mm, yana oke ruru 20000 kgs.

Ogologo kachasị na obosara maka ogwe dị larịị na ogwe square bụ 1500mm, yana oke dị 26000 kgs.

A na-emepụta mmanya a kpụrụ akpụ ma ọ bụ osisi a na-apịaji site n'iwere ihe ingot ma mee ka ọ dịkwuo nha site na, n'ozuzu, ọnụ ụlọ abụọ na-emegide ya na-anwụ. Ọla ndị a kpụrụ akpụ na-adị ike, sie ike ma na-adịte aka karịa ụdị nkedo ma ọ bụ akụkụ arụpụtara. Ị nwere ike nweta usoro ọka a rụrụ n'akụkụ niile nke forgings, na-abawanye ike akụkụ nke ike iguzogide agha na iyi.

Shanxi DongHuang Wind Power Flange Manufacturing Co., LTD., Dị ka onye na-emepụta akwụkwọ ikike nke ISO debanyere aha, na-ekwe nkwa na forgings na / ma ọ bụ ụlọ mmanya na-adakọ ọnụ na ịdị mma na enweghị ihe ọ bụla nke na-emebi ihe eji arụ ọrụ ma ọ bụ ihe eji arụ ọrụ.

Ikpe:

Ọkwa ígwè EN 1.4923 X22CrMoV12-1

Ọdịdị Martensitic

| Ngwakọta kemịkalụ% nke ígwè X22CrMoV12-1 (1.4923): EN 10302-2008 | ||||||||

| C | Si | Mn | Ni | P | S | Cr | Mo | V |

| 0.18 - 0.24 | kacha 0.5 | 0.4-0.9 | 0.3-0.8 | Ọnụahịa kasị elu nke 0.025 | kacha elu 0.015 | 11-12.5 | 0.8-1.2 | 0.25 - 0.35 |

Ngwa

Igwe ọkụ, injinia igwe, nrụpụta ike.

Ngwa maka ahịrị ọkpọkọ, igwe ọkụ uzuoku na turbines.

Ụdị nnyefe

Ogwe gbara okirikiri, mgbanaka Forgings Rolled, Ogwe okirikiri na-agwụ ike, mmanya X22CrMoV12-1 akpara akpa

Nha: φ58x 536L mm.

Ịrụ ọrụ (Na-ekpo ọkụ) Omume

A na-ebunye ihe n'ọkụ na ọkụ. Mgbe okpomọkụ ruru 1100 ℃, metal ga-ekpu. Ọ na-ezo aka ọ bụla n'ibu usoro na shapes metal ulilizing otu ma ọ bụ karịa anwụ, eg-emeghe/emechi anwụ forging, extrusion, Rolling, wdg N'oge usoro a, okpomọkụ nke metal dara. Mgbe ọ na-agbada ruo 850 ℃, metal ga-ekpo ọkụ ọzọ. Mgbe ahụ megharịa ọkụ ọrụ na elu okpomọkụ (1100 ℃). Oke kacha nta maka oke ọrụ ọkụ sitere na ingot ruo billet bụ 3 ruo 1.

Usoro ọgwụgwọ okpomọkụ

Bunye ihe eji eme ihe na-ekpo ọkụ na-ekpo ọkụ n'ime ọgwụgwọ ọkụ. Kpoo ọkụ na okpomọkụ nke 900 ℃. Jide na okpomọkụ maka awa 6 5 nkeji. Mmanụ na-emenyụ na iwe na 640 ℃. Mgbe ahụ, ikuku dị jụụ.

Nrụ ọrụ igwe nke X22CrMoV12-1 mmanya akpara akpa (1.4923).

| Rm - Ike ntakiri (MPa) (+QT) | 890 |

| Rp0.20.2% ike ihe akaebe (MPa) (+QT) | 769 |

| KV - ike mmetụta (J) (+QT) | -60° 139 |

| A - Min. elongation na mgbaji (%) (+QT) | 21 |

| Isi ike brinell (HBW): (+A) | 298 |

Enwere ike ịme akara akara ihe ọ bụla, karịa nke a kpọtụrụ aha n'elu, dịka onye ahịa chọrọ.

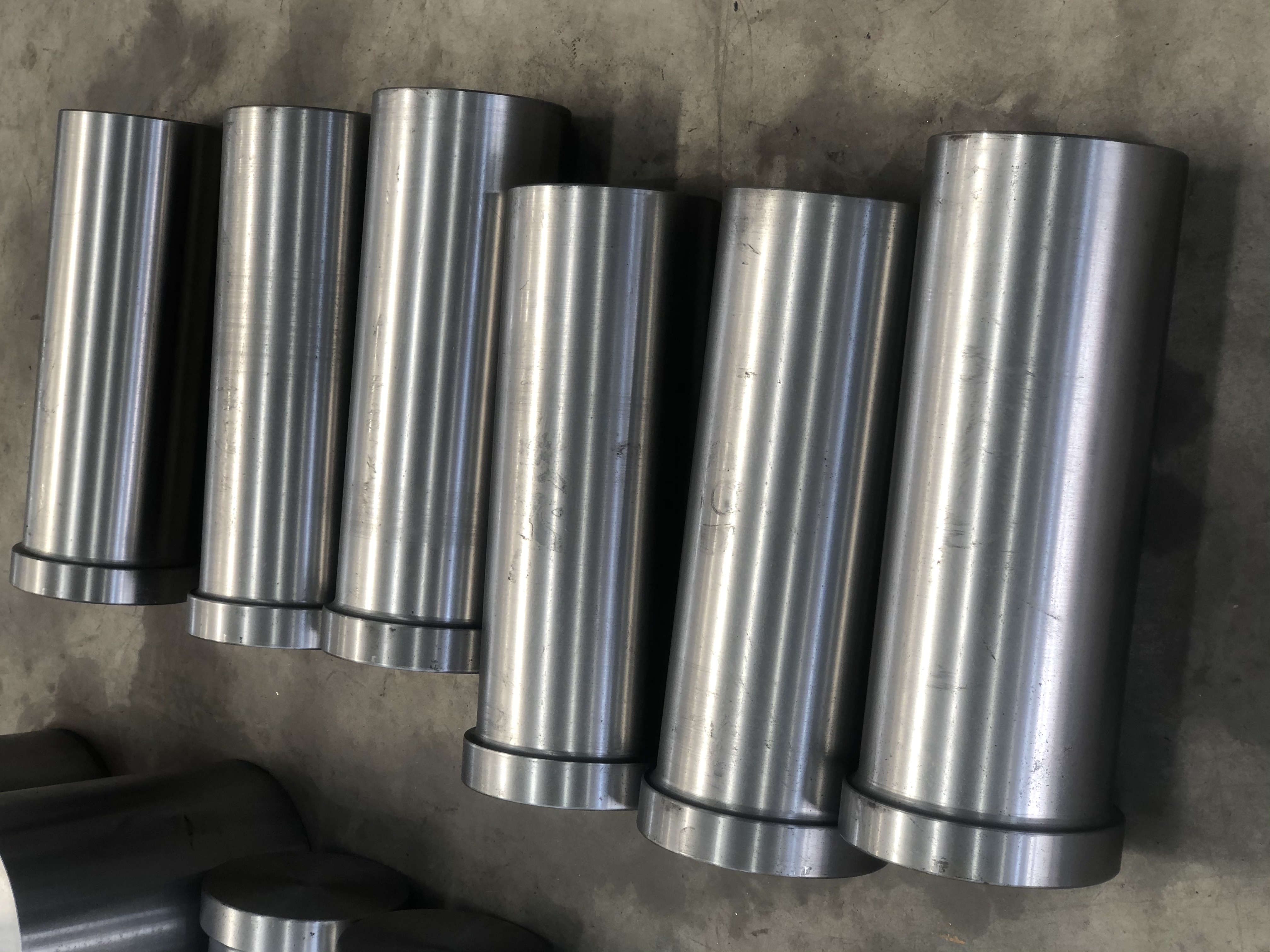

Foto nkọwa ngwaahịa:

Ntuziaka ngwaahịa emetụtara:

Were ọrụ zuru oke iji gboo mkpa niile nke ndị ahịa anyị; nweta ọganihu na-aga n'ihu site n'ịkwado mgbasawanye nke ndị na-azụ anyị; turn into the final permanent cooperative partner of clientele and maximize the interest of clients for Discount wholesale Plate Forging Tube Pipe - Forged Bars – DHDZ , The ngwaahịa ga-ezitere ụwa nile, dị ka: Indonesia, Honduras, kazan, We have constructed mmekọrịta siri ike na ogologo oge yana nnukwu ụlọ ọrụ dị na azụmahịa a na Kenya na esenidụt. Ngwa ngwa na ọkachamara mgbe ọrịre ahịa wetara site na ndị ndụmọdụ anyị nwere obi ụtọ ndị na-azụ anyị. Enwere ike iziga gị ozi zuru ezu na parampat sitere na ngwa ahịa maka nnabata ọ bụla nke ọma. Enwere ike ibunye ihe nlele efu na ụlọ ọrụ lelee ụlọ ọrụ anyị. A na-anabata Kenya maka mkparịta ụka mgbe niile. Na-atụ anya ịnweta ajụjụ pịnye gị wee wulite mmekọrịta nkwado ogologo oge.

Ngwaahịa dị ugbu a natara, anyị nwere afọ ojuju, ezigbo onye na-eweta ngwaahịa, na-atụ anya ime mgbalị siri ike iji mee nke ọma.