Xov xwm

-

Ua kev zoo siab rau kev rov pib ua haujlwm

Zoo siab nrog rau kev rov pib ua haujlwm Nyob zoo cov neeg siv khoom tshiab thiab qub thiab cov phooj ywg, Nyob Zoo Xyoo Tshiab. Tom qab lub caij nplooj ntoos hlav zoo siab hnub so, Lihuang Group (DHDZ) tau pib ua haujlwm ib txwm nyob rau lub Ob Hlis 18th. Txhua yam ...Nyeem ntxiv -

DHDZ forging 2020 xyoo kev tshuaj xyuas lub rooj sib tham thiab 2021 txais tos tog rau cov tub ntxhais kawm tshiab

2020 yog lub xyoo txawv tshaj plaw, muaj kev sib kis, thoob plaws lub tebchaws nyuaj, lub xeev loj hauv nruab nrog cev thiab qee lub lag luam, me me rau txhua tus neeg ua haujlwm thiab cov neeg zoo tib yam, txhua tus dais qhov kev sim loj ...Nyeem ntxiv -

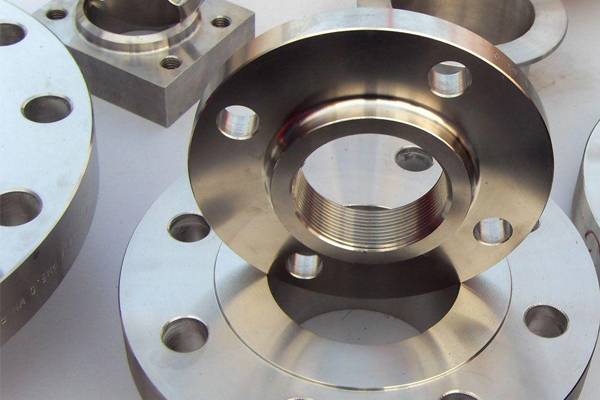

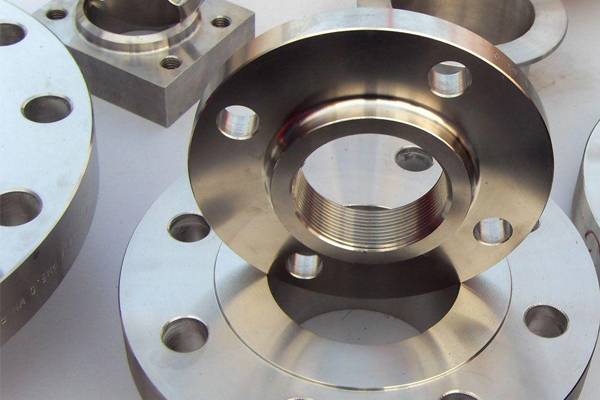

Yuav ua li cas thiaj nrhiav tau cov teeb meem ua haujlwm ntawm stainless hlau flange

Ua ntej ntawm tag nrho cov, ua ntej xaiv qhov xyaum me ntsis, ua tib zoo saib cov teeb meem nyob rau hauv stainless hlau flange ua. Tshawb nrhiav qhov nyuaj tuaj yeem yog qhov tseeb, nrawm heev los nrhiav kev siv cov dri ...Nyeem ntxiv -

Dab tsi yog txheej txheem ntawm forging?

1. Isothermal forging yog ua kom qhov kub ntawm billet tas li thaum lub sij hawm tsim tag nrho. Isothermal forging yog siv los ua kom zoo dua ntawm cov yas siab ntawm qee cov hlau ntawm consta ...Nyeem ntxiv -

Lub ntsiab tsis zoo ntawm cov dej ua quenching txias nruab nrab rau forgings?

1) nyob rau hauv austenite isothermal transformation daim duab ntawm cov cheeb tsam raug, uas yog, hais txog 500-600 ℃, dej nyob rau hauv lub chav zaj duab xis theem, qhov txias npaum li cas yog tsis ceev txaus, feem ntau ua rau uneven txias ib ...Nyeem ntxiv -

Dab tsi ntawm txoj hlua txuas txuas stainless hlau flange siv?

Cov neeg muas zaub feem ntau nug: stainless hlau flange kev twb kev txuas seb puas yuav xaiv stainless hlau bolts? Tam sim no kuv yuav sau qhov kuv tau kawm los qhia rau koj: Cov ntaub ntawv tsis muaj dab tsi nrog cov khoom ...Nyeem ntxiv -

Yuav ua li cas siv vuam flange kom raug

Flanges Nrog txoj kev loj hlob sai ntawm kev siv hluav taws xob txawv teb chaws hauv kev tsim cov kav dej, cov kav xa dej siab tau dhau los ua qhov txuas tseem ceeb, ua ntej thiab tom qab kev sim siab, yuav tsum dhau t ...Nyeem ntxiv -

Kev siv ntawm hardenability thiab hardenability ntawm forgings

Hardenability thiab hardenability yog cov Performance indexes uas characterize lub quenching peev xwm ntawm forgings, thiab lawv kuj yog lub hauv paus tseem ceeb rau xaiv thiab siv cov ntaub ntawv.Hardenabilit ...Nyeem ntxiv -

Txoj kev los txhim kho lub plasticity ntawm forging thiab txo cov deformation kuj

Txhawm rau kom yooj yim rau kev khiav ntawm cov hlau billet, txo qhov deformation tsis kam thiab txuag cov cuab yeej siv zog, cov hauv qab no feem ntau tau txais hauv cov txheej txheem forging: 1) tuav lub ma...Nyeem ntxiv -

Flange txheem

Flange tus qauv: Lub teb chaws tus qauv GB / T9115-2000, Ministry of Machinery STANDARD JB82-94, Ministry of Chemical Industry standard HG20595-97HG20617-97, Ministry of Electric Power standard GD0508 ~ 0 ...Nyeem ntxiv -

Dab tsi yog cov txheej txheem ntawm forging tu

Forgings tu yog cov txheej txheem ntawm kev tshem tawm qhov tsis xws luag ntawm forgings los ntawm kev siv tshuab lossis tshuaj. Txhawm rau txhim kho qhov zoo ntawm forgings, txhim kho qhov kev txiav ntawm forging ...Nyeem ntxiv -

Qhov tsis xws thiab Countermeasures ntawm loj forgings: Uneven microstructure thiab cov khoom

Loj forgings, vim lawv qhov loj me, ntau cov txheej txheem, lub voj voog ntev, tsis sib xws hauv cov txheej txheem, thiab ntau yam tsis ruaj khov, feem ntau ua rau muaj qhov tsis sib xws hauv microstructure, kom lawv ...Nyeem ntxiv