1. Isothermal forgingyog kom qhov kub ntawm billet tas li thaum lub sij hawm tag nrho cov txheej txheem.Isothermal forgingyog siv los ua kom zoo dua ntawm cov yas siab ntawm qee cov hlau ntawm qhov kub thiab txias los yog kom tau txais cov qauv tshwj xeeb thiab cov khoom. Isothermal forging yuav tsum tau pwm thiab billet khaws cia ntawm qhov kub thiab txias ua ke, uas yuav tsum muaj tus nqi siab thiab tsuas yog siv rau kev tshwj xeeb forging thiab nias cov txheej txheem, xws li superplastic sib sau.

2. Forgingtuaj yeem hloov cov qauv hlau thiab txhim kho kev ua haujlwm hlau. Tom qabkub forginglub ingot, tus thawj cam khwb cia lub xeev ntawm xoob, pore, micro tawg yog compacted los yog welded; Tus thawj dendritic siv lead ua yog tawg los ua cov nplej zoo. Nyob rau tib lub sij hawm, hloov cov thawj carbide segregation thiab kev faib tsis sib xws, kom lub koom haum yog uniform, thiaj li yuav tau txais internal ntom, uniform, nplua, zoo kev ua tau zoo, txhim khu kev qha siv forgings. Tom qabkub forgingdeformation, cov hlau yog fibrous qauv; Tom qab txias forging deformation, cov hlau muaju qhia kev txiav txim.

3.forgingyog ua kom cov hlau yas ntws thiab ua rau hauv cov duab uas xav tau ntawm lub workpiece. Lub ntim ntawm cov hlau tsis hloov pauv tom qab cov yas ntws los ntawm sab nraud quab yuam, thiab cov hlau ib txwm ntws mus rau qhov tsawg kawg nkaus tsis kam. Hauv kev tsim khoom, cov duab ntawm lub workpiece feem ntau tswj tau raws li cov cai no, thiab qhov deformation ntawm kev ntxhov siab ntawm kev kos duab, reaming, dabtsi yog khoov thiab sib sib zog nqus nqus yog pom tau.

4.tusforging workpieceqhov loj me yog qhov tseeb, tsim nyog rau lub koom haum ntawm kev tsim khoom loj.Tuag forging, extrusion, stamping thiab lwm yam kev siv ntawm cov pwm tsim loj yog qhov tseeb thiab ruaj khov. High npaum forging machinery thiab tsis siv neeg forging ntau lawm kab yuav siv tau los npaj tshwj xeeb pawg ntau lawm los yog loj ntau lawm.

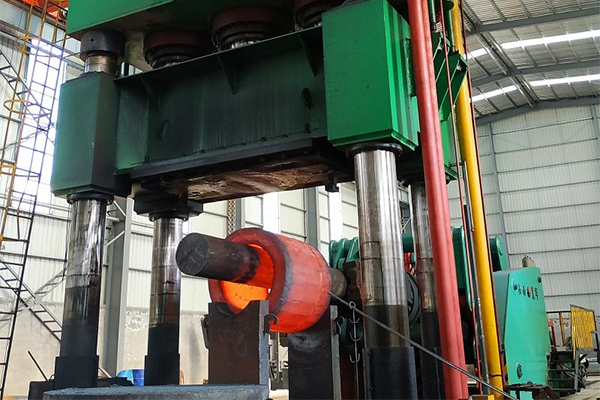

5.Cov txheej txheem ntau lawm ntawmforgingsuav nrog blanking, cua sov thiab pretreatment ntawm forging dawb paug ua ntej sib sau; Kev kho cua sov, tu, calibration thiab tshuaj xyuas ntawm workpiece tom qab tsim. Feem ntau siv forging machinery muaj forging rauj, hydraulic xovxwm thiab mechanical press. Forging rauj muaj qhov cuam tshuam loj tshaj plaws, uas yog qhov zoo rau cov hlau yas ntws, tab sis nws yuav tsim kev co; Cov xovxwm hydraulic siv qhov zoo li qub forging, yog qhov zoo rau forging los ntawm cov hlau thiab lub koom haum txhim kho, kev ua haujlwm ruaj khov, tab sis cov khoom tsim tau tsawg; Cov tshuab xovxwm tau kho mob stroke, uas yog ib qho yooj yim kom paub txog tshuab thiab automation.

Nyob rau hauv lub neej yav tom ntej, lubforging tshuabyuav txhim kho lub internal zoo ntawmforging qhov chaw, txhim kho precisionforgingthiab precision stamping tshuab, tsimforging khoomthiabforging ntau lawmkab nrog ntau dua productivity thiab automation degree, tsimhloov tau forgingtsim system, thiab tsim tshiabforging cov ntaub ntawvthiabforging uatxoj kev. Txhawm rau txhim kho qhov zoo ntawm sab hauvforgings, nws yog tsuas yog los txhim kho lawv cov khoom siv kho tshuab (lub zog, plasticity, toughness, qaug zog) thiab kev ntseeg tau. Qhov no yuav tsum tau siv zoo dua ntawm cov hlau yas deformation txoj kev xav; Siv cov ntaub ntawv zoo dua qub; Kho cua sov ua ntej forging thiab forging cua sov kho; Ntau nruj thiab dav tsis muaj kev sim ntawm forgings.

Post lub sij hawm: Jan-25-2021