LH-VOC-RTO

Khoom nthuav dav

Lub homphiaj thiab thaj tsam

RTOyog tsim rau cov organic khib nyiab kho hauv tsheb thiab tshuab tsim, txheej kab thiab ziab chav; hluav taws xob tsim khoom, luam tawm Circuit Board (PCB) organic pov tseg roj kho; hluav taws xob tsim, enameled hlau rwb thaiv tsev organic pov tseg roj kho; lub teeb kev lag luam, khau-ua kua nplaum organic pov tseg gas kho; luam ntawv thiab xim luam ntawv organic pov tseg roj kho.

Nws yog qhov tsim nyog rau kev kho cov pa roj carbon monoxide hauv kev lag luam hlau metallurgical thiab carbon electrode ntau lawm; kev kho cov organic pov tseg roj hauv kev lag luam tshuaj thiab cov txheej txheem chemical synthesis (ABS synthesis).

Nws yog qhov tsim nyog rau ntau qhov chaw uas cov khoom siv khib nyiab tau tsim tawm xws li cov khoom siv khib nyiab hauv cov roj av refining thiab cov txheej txheem tshuaj.

Txoj cai ntawm kev ua haujlwm

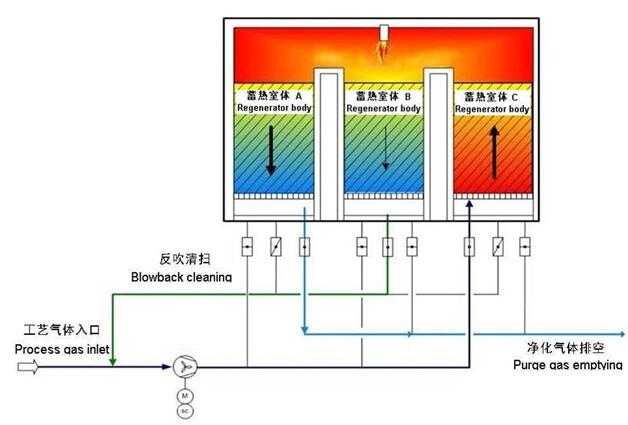

Ua ntej kev kho cua sov ntawm lub qhov cub lub cev, lub combustion chamber thiab lub txaj regenerative yog preheated; Tom qab lub preheating tiav lawm, qhov tso pa tawm yog txuas nrog cov khoom siv. Cov organic pov tseg roj yog thawj zaug hloov pauv los ntawm lub preheated tshav kub cia ceramic lub cev 1 nyob rau hauv qhov kev txiav txim ntawm tus kiv cua txhawb. Cov pa khib nyiab nkag mus rau hauv qhov chaw cua sov tom qab qhov kub thiab txias. Hauv cheeb tsam cua sov, cov pa tso pa tawm yog cua sov rau zaum ob. Tom qab cov tshuaj tiv thaiv kub yuav tsum tau, nws nkag mus rau hauv lub catalytic chamber rau cov tshuaj tiv thaiv, generates carbon dioxide thiab dej thiab tso tawm thiab tso tawm cua sov zog; cov roj uas tau kho kom huv si dhau los ntawm cov cua kub cia hauv lub cev 2 rau kev cia cua sov thiab tawm los ntawm tus kiv cua. Thaum qhov ntsuas kub tau kuaj pom los ntawm qhov ntsuas qhov ntsuas kub ntawm qhov nkag ntawm lub kiv cua tso tawm thiab qhov ntsuas kub tau mus txog, lub valve tau hloov los ntawm cov khoom siv hluav taws xob kub ntawm lub cev 2 mus rau cov pa tso pa tawm, thiab cov cua kub cia hauv lub cev 1 yog tawm, thiab lub voj voog rov ua dua.

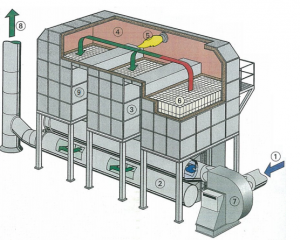

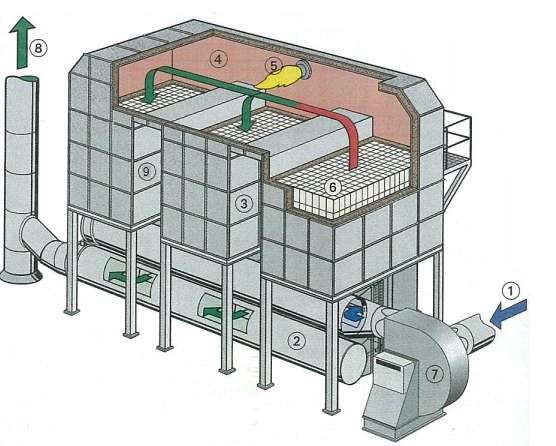

3-Chamber RTO txheej txheem khiav daim ntawv qhia

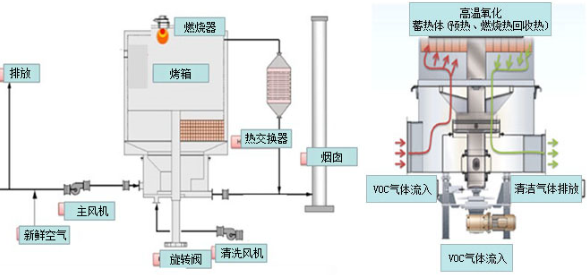

Rotary RTO txheej txheem flow chart

Technical yam ntxwv

1. Nws txais kev hloov pauv hloov thev naus laus zis ntawm preheating thiab khaws cia kom sov kom nws muaj kev sib pauv hluav taws xob ntau dua, kev ua haujlwm siab li 90-95% lossis ntau dua, thiab kev txuag hluav taws xob yog qhov zoo tshaj plaws.

2. Lub tshuab hluav taws xob yog siv rau cua sov, uas tuaj yeem paub txog kev hloov pauv hloov pauv ntawm kev ua haujlwm siab thiab tsis muaj zog, thiab muaj kev ua haujlwm ntawm kev ntxuav ua ntej, kev tiv thaiv flameout, tshaj kub tswb thiab tsis siv neeg roj muab txiav tawm; kev ua haujlwm muaj kev nyab xeeb, txhim khu kev qha, ua haujlwm tau zoo thiab ruaj khov.

3. Nws siv microcomputer tsis siv neeg tswj thiab ntau qhov ntsuas kub tswj kom paub txog ntau yam kev tiv thaiv, kev ua haujlwm cov ntaub ntawv rov qab, thiab saib xyuas cov ntaub ntawv tawm tswv yim, kom lub kaw lus tuaj yeem ua haujlwm zoo, ruaj khov thiab ntseeg tau.

4. Lub valve txais yuav lub tshuab pneumatic kis tau tus mob, uas yog rhiab heev thiab sai dua li lub tshuab xa hluav taws xob.

5. Cov roj tso tawm los ntawm lub tshuab incineration muaj cov ntsiab lus tsawg: VOC <120mg/Nm³, CO<100 mg/Nm³, NOx<100 mg/Nm³.

Peb yuav xaiv cov cuab yeej zoo li cas?

| Specifications thiab cov qauv | LH-VOC-RTO- 3000 | LH-VOC-RTO- 5000 | LH-VOC-RTO- 10000 | LH-VOC-RTO- 15000 | LH-VOC-RTO- 20000 | LH-VOC-RTO- 30000 | LH-VOC-RTO- 40000 | LH-VOC-RTO- 50000 | LH-VOC-RTO- 60000 | |

| Kev kho cua ntws m³/h | 3000 | 5000 | 10000 | 15000 | 20000 | 30000 | 40000 | 50000 | 60000 | |

| Organic gas concentration | 100-8000mg / m³(sib tov) | |||||||||

| Hom ntawm Organic gas | Triphenyl, cawv, ether, aldehyde, phenol, ketone, ester thiab lwm yam VOC; malodorous gas, thiab lwm yam. | |||||||||

| Regenerator cua sov rov qab efficiency | ≥95% | |||||||||

| Purification efficiency | ≥98-99% | |||||||||

| Cov khoom siv loj | Ntev(mm) | ib 6280 | ib 6280 | ib 8375 | ib 9690 | 10600 ib | ib 14265 | ib 15180 | ib 16095 | 17925 ib |

| Dav(mm) | 1550 | Xyoo 1880 | 2135 ib | 2440 ib | 2745 ib | 2745 ib | 3 050 | ib 3660 | ib 3660 | |

| Qhov siab(mm) | 5000 | 5600 ib | 5600 ib | 6000 | 6500 ib | 7000 | 7000 | 7500 ib | 7500 ib | |

| Maximum tso zis kub tus nqi ntawm burner(kcal / h) | 14×10⁴ | 25×10⁴ | 25×10⁴ | 60×10⁴ | 100×10⁴ | 100×10⁴ | 120×10⁴ | 200×10⁴ | 200×10⁴ | |

| Roj noj | pib | Cov zis ntau tshaj ntawm cov burner | ||||||||

| ib txwm ua haujlwm | Kev txiav txim siab raws li cov pa tso pa tawm, thaum lub concentration siab dua 1600 ~ 2000mg / Nm³, RTO tuaj yeem tswj tau qhov sib txawv ntawm qhov sib txawv. | |||||||||

| Lub txaj siab poob | ≤3500 Ib | |||||||||

Nco tseg:

1. Lwm qhov tshwj xeeb ntawm huab cua ntim tuaj yeem tsim nyias.

2. Yog tias muaj qhov yuav tsum tau ua rau roj, thov qhia thaum xaj.

3. Siv ob-chamber lossis peb-chamber lossis rotary RTO raws li cov neeg siv peev thiab cov khoom siv purification efficiency.

Qhov project case

Cov pa hluav taws xob yug los ntawm X pib qhov chaw tsim khoom lag luam yog 50,000 m³ / h, thiab voc concentration yog li 200-300mg / m³. Rau qhov zoo ntawm cov ntim siab thiab qis-concentration organic pov tseg roj, Peb DHDZ thiab LH siv filtration + UV pretreatment + concentrated nruas + rotating RTO thev naus laus zis kom tsim nyog cov pa khib nyiab! Rhiav cov pa khib nyiab yog sau los ntawm cov kav dej rau kev tshem tawm cov plua plav thiab pom, tom qab ntawd kho ua ntej, thiab tom qab ntawd dhau los ntawm tus khiav tom qab adsorption, tawm mus rau tus qauv.

Lim + pretreatment + rotating nruas + rotating RTO khib nyiab kev kho cov txheej txheem muaj cov yam ntxwv ntawm kev ruaj khov thiab txhim khu kev qha kev lag luam thiab qib siab ntawm automation. Tom qab cov khoom siv tau qhib, nws tuaj yeem ua rau tsis muaj neeg saib xyuas. Thiab tag nrho cov cuab yeej yog interlocked nrog lub rhiav ntau lawm kab tswj system flexibly kho lub sij hawm pib thiab nres, tsis muaj ntxiv phau ntawv ua hauj lwm. Nws yog cov txheej txheem nyiam rau kev kho cov pa tso pa tawm ntawm cov tuam txhab tshuaj tsuag!