Hoobkas pheej yig yas Flange - Forged Bars - DHDZ

Hoobkas pheej yig yas Flange - Forged Bars - DHDZ Nthuav dav:

Qhib Tuag Forgings Chaw tsim tshuaj paus nyob rau hauv Suav teb

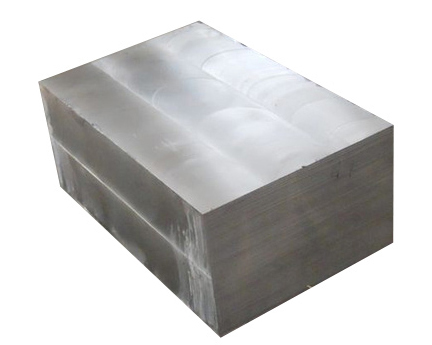

Forged Bars

Khoom siv: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 | 42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30 NiCrMo12 | 22NiCrMoV12

FORGED BAR SIAB

Round bars, Square bar, tiaj tiaj bar thiab Hex tuav. Tag nrho cov hlau muaj lub peev xwm forging los tsim cov tuav los ntawm cov nram qab no alloy hom:

● Alloy hlau

● Carbon steel

● Stainless hlau

FORGED BAR muaj peev xwm

ALLOY

MAX WIDTH

MAX WEIGHT

Carbon, hlau

1500 hli

26 000 Kg

Stainless hlau

800 hli

20000 kgs

FORGED BAR muaj peev xwm

Qhov ntev tshaj plaws rau forged round bars thiab hex bars yog 5000 mm, nrog rau qhov hnyav tshaj plaws ntawm 20000 kgs.

Qhov siab tshaj plaws ntev thiab dav rau cov kab tiaj tiaj thiab square bar yog 1500mm, nrog qhov hnyav tshaj plaws ntawm 26000 kgs.

Lub forged bar los yog ib lub dov bar yog tsim los ntawm kev noj ib qho ingot thiab forging nws mus rau qhov loj los ntawm, feem ntau, ob qho tib si tawm tsam tuag. Forged hlau zoo li yuav muaj zog, nyuaj thiab ruaj khov dua li cov ntaub ntawv cam khwb cia lossis machined qhov chaw. Koj tuaj yeem tau txais cov qauv wrought grain thoob plaws txhua ntu ntawm forgings, ua kom qhov chaw muaj peev xwm tiv taus kev sib tsoo thiab hnav.

Shanxi DongHuang Cua Fais Fab Flange Manufacturing Co., LTD., raws li ISO sau ntawv pov thawj forging chaw tsim tshuaj paus, lav tias cov forgings thiab / los yog tuav yog homogenous nyob rau hauv zoo thiab tsis muaj anomalies uas yog detrimental rau txhua yam khoom los yog machining properies ntawm cov khoom.

Case:

Hlau Qib EN 1.4923 X22CrMoV12-1

Qauv Martensitic

| Cov tshuaj muaj pes tsawg leeg ntawm steel X22CrMoV12-1 (1.4923): EN 10302-2008 | ||||||||

| C | Si | Mn | Ni | P | S | Cr | Mo | V |

| 0.18-0.24 dr hab | max 0.5 hli | 0.4-0.9 hli | 0.3-0.8 hli | max 0.025 | max 0.015 | 11-12.5 Nws | 0.8-1.2 hli | 0.25-0.35 Nws |

Daim ntawv thov

Powerplant, Tshuab engineering, tsim hluav taws xob.

Cheebtsam rau cov yeeb nkab-kab, chav boilers thiab turbines.

Daim ntawv xa tuaj

Round bar, Rolled Forgings Rings, Bored roundbars, X22CrMoV12-1 Forged bar

Loj: φ58x536L mm.

Forging (Hot Work) xyaum

Cov ntaub ntawv yog loaded nyob rau hauv lub cub tawg thiab rhuab. Thaum kub txog 1100 ℃, hlau yuav forged. Nws yog hais txog txhua yam txheej txheem uas tsim cov hlau ulilizing ib los yog ntau dua tuag, piv txwv li qhib / kaw tuag forging, extrusion, dov, thiab lwm yam. Thaum lub sij hawm tus txheej txheem no, lub temperture ntawm hlau ntog. Thaum nws txo qis rau 850 ℃, hlau yuav rov ua dua. Tom qab ntawd rov ua haujlwm kub ntawm qhov kub siab (1100 ℃). Qhov tsawg kawg nkaus piv rau kub ua hauj lwm piv ntawm ingot mus rau billet yog 3 mus rau 1.

Kev kho cua sov txheej txheem

Thauj lub preheat kho machining cov ntaub ntawv mus rau hauv kev kho cua sov furance. Kub rau qhov kub ntawm 900 ℃. Tuav ntawm qhov kub li 6 teev 5 feeb. Roj quench thiab temper ntawm 640 ℃.Tom qab cua-txias.

Mechanical zog ntawm X22CrMoV12-1 forged bar (1.4923).

| Rm - Tensile zog (MPa) (+ QT) | 890 ua |

| rp0.2 ua0.2% pov thawj lub zog (MPa) (+ QT) | 769 ib |

| KV - Impact zog (J) (+ QT) | -60 ° 139 |

| A - Min. elongation ntawm tawg (%) (+ QT) | 21 |

| Brinell hardness (HBW): (+A) | 298 |

Txhua yam ntaub ntawv qib, uas tsis yog hais los saum toj no, tuaj yeem raug forged raws li tus neeg siv khoom xav tau.

Product details duab:

Yam khoom Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" will be the persistent conception of our enterprise with the long-term to build with each other with customers for mutual reciprocity and mutual advantage for Factory Pheej yig Plastic Flange - Forged Bars - DHDZ , Cov khoom yuav muab rau tag nrho cov thoob lub ntiaj teb no, xws li: cov neeg siv khoom zoo thiab cov khoom lag luam zoo, cov khoom lag luam zoo thiab cov khoom lag luam, xws li: cov neeg siv khoom lag luam, cov khoom lag luam zoo thiab cov khoom lag luam, cov khoom lag luam, cov khoom lag luam, kev lag luam, kev lag luam, kev lag luam, kev lag luam, kev lag luam, kev lag luam, kev lag luam thiab lub koob npe nrov. Muab 'Cov Khoom Siv Zoo, Kev Pabcuam Zoo, Cov Nqi Sib Tw thiab Kev Xa Khoom sai', tam sim no peb tab tom tos ntsoov kom muaj kev koom tes ntau dua nrog cov neeg siv khoom txawv teb chaws raws li kev sib nrig sib pab. Peb yuav ua haujlwm tag nrho lub siab los txhim kho peb cov khoom thiab cov kev pabcuam. Peb kuj tau cog lus tias yuav ua haujlwm nrog cov neeg koom tes ua lag luam los txhawb peb txoj kev koom tes mus rau qib siab dua thiab sib koom ua tiav ua ke. Zoo siab txais tos koj tuaj xyuas peb lub Hoobkas ua tsaug.

Lub tuam txhab cov khoom tuaj yeem ua tau raws li peb cov kev xav tau sib txawv, thiab tus nqi pheej yig, qhov tseem ceeb tshaj plaws yog qhov zoo kuj zoo heev.