2019 Tuam Tshoj Tshiab Tsim Dawb Forgings - Forged Blocks - DHDZ

2019 Tuam Tshoj Tshiab Tsim Dawb Forgings - Forged Blocks - DHDZ nthuav dav:

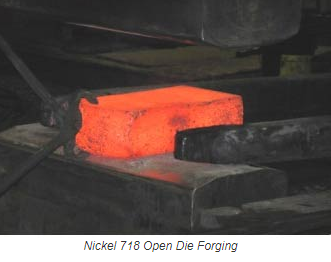

Qhib Tuag Forgings Chaw tsim tshuaj paus nyob rau hauv Suav teb

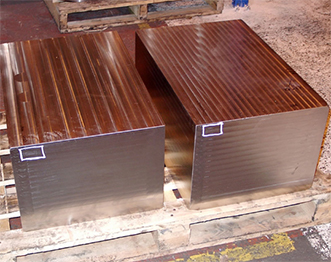

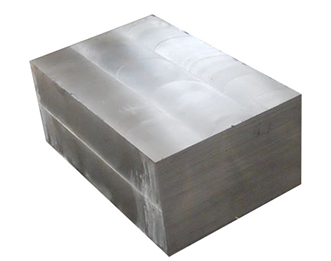

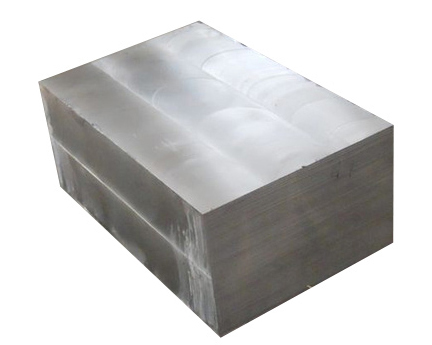

Forged Block

Forged blocks yog qhov zoo dua li cov phaj vim qhov thaiv muaj forging txo ntawm tag nrho plaub mus rau rau sab yog tias xav tau los ntawm daim ntawv thov. Qhov no yuav tsim cov qauv ua kom zoo zoo uas yuav ua kom tsis muaj qhov tsis xws luag thiab cov khoom siv zoo. Qhov siab tshaj plaws forged thaiv qhov ntev nyob ntawm cov khoom siv qib.

Khoom siv: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 | 42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30 NiCrMo12 | 22NiCrMoV

FORGED BLOCK

Loj xovxwm forged blocks mus txog 1500mm x 1500mm seem nrog qhov ntev kuj sib txawv.

Thaiv forging kam rau ua feem ntau -0 / + 3mm txog +10mm nyob ntawm qhov loj me.

Tag nrho cov hlau muaj lub peev xwm forging los tsim cov tuav los ntawm cov nram qab no alloy hom:

● Alloy hlau

● Carbon steel

● Stainless hlau

FORGED Block CAPABILITIES

Khoom siv

MAX WIDTH

MAX WEIGHT

Carbon, hlau alloy

1500 hli

26 000 Kg

Stainless hlau

800 hli

20000 kgs

Shanxi DongHuang Cua Fais Fab Flange Manufacturing Co., LTD., raws li ISO sau ntawv pov thawj forging chaw tsim tshuaj paus, lav tias cov forgings thiab / los yog tuav yog homogenous nyob rau hauv zoo thiab tsis muaj anomalies uas yog detrimental rau txhua yam khoom los yog machining properies ntawm cov khoom.

Case: Hlau Qib C1045

| Chemical muaj pes tsawg leeg ntawm steel C1045 (UNS G10450) | |||

| C | Mn | P | S |

| 0.42-0.50 Nws | 0.60-0.90 Nws | max 0.040 | max 0.050 |

Daim ntawv thov

Valve lub cev, hydraulic manifolds, lub siab hlab ntsha Cheebtsam, mounting blocks, tshuab cuab yeej Cheebtsam, thiab turbine hniav

Daim ntawv xa tuaj

Square bar, offset square bar, forged block.

C1045 Forged Block

Loj: W 430 x H 430 x L 1250mm

Forging (kub ua hauj lwm) xyaum, kev kho cua sov txheej txheem

| Forging | 1093-1205 ℃ |

| Annealing | 778-843 ℃ cub txias |

| Tempering | 399-649 ℃ |

| normalizing | 871-898 ℃ cua txias |

| Austenize | 815-843 ℃ dej quench |

| Kev ntxhov siab | 552-663 ℃ |

| Rm - Tensile zog (MPa) (N + T) | 682 ib |

| rp0.2 ua0.2% pov thawj lub zog (MPa) (N + T) | 455 |

| A - Min. elongation ntawm tawg (%) (N + T) | 23 |

| Z - Txo hauv ntu ntu ntawm pob txha (%) (N + T) | 55 |

| Brinell hardness (HBW): (+A) | 195 |

Cov ntaub ntawv ntxiv

THOV QHIA NTAU HNUB NO

LOSSIS Hu rau: 86-21-52859349

Product details duab:

Yam khoom Guide:

Peb lub hom phiaj kom nkag siab zoo disfigurement nrog cov zis thiab muab cov kev pabcuam sab saum toj rau cov neeg siv khoom hauv tsev thiab txawv teb chaws tag nrho rau xyoo 2019 Tuam Tshoj Tshiab Tsim Dawb Forgings - Forged Blocks - DHDZ , Cov khoom yuav muab rau thoob plaws lub ntiaj teb, xws li: Southampton, Adelaide, Afghanistan, Peb zoo siab tos txais koj tuaj xyuas peb lub tuam txhab thiab lub Hoobkas. Nws kuj yog ib qho yooj yim mus xyuas peb lub vev xaib. Peb pab neeg muag khoom yuav muab kev pabcuam zoo tshaj rau koj. Yog tias koj xav paub ntau ntxiv, thov hu rau peb ntawm E-mail lossis xov tooj. Peb vam thiab cia siab tias yuav tsim kom muaj kev sib raug zoo ntawm kev lag luam mus sij hawm ntev nrog koj los ntawm lub sijhawm no, raws li kev sib luag, kev sib raug zoo los ntawm tam sim no mus rau yav tom ntej.

Txawm peb yog ib lub tuam txhab me me los peb kuj hwm thiab. Kev ntseeg tau zoo, kev pabcuam siab dawb thiab credit zoo, peb zoo siab los ua haujlwm nrog koj!