100% Thawj Hoobkas Kub Forging - Forged Cov Nrig - DHDZ

100% Thawj Hoobkas kub forging - forged blocks - DHDZ nthuav dav:

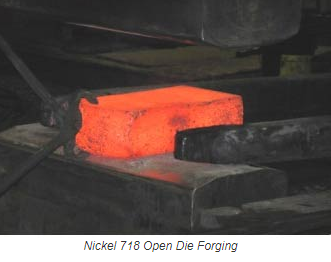

Qhib Tuag Forgings Chaw tsim tshuaj paus hauv Suav

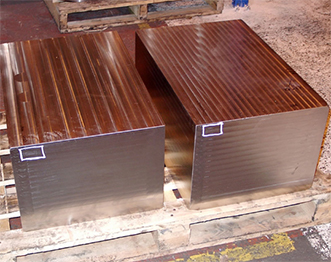

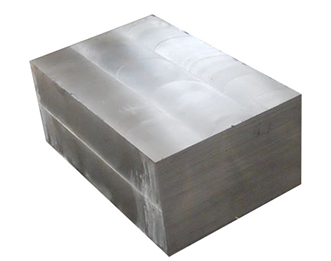

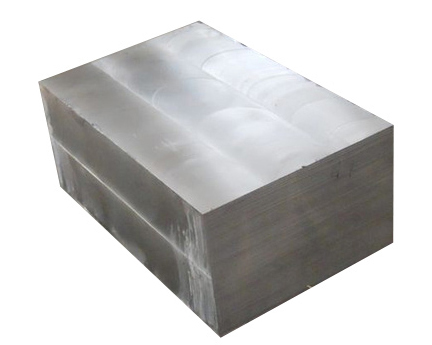

Forged thaiv

Forged cov blocks yog cov khoom lag luam siab dua li phaj vim yog cov block muaj kev zam txim rau tag nrho plaub mus rau rau sab yog tias yuav tsum tau los ntawm daim ntawv thov. Qhov no yuav tsim cov qauv ua kom zoo nkauj uas yuav ua kom muaj qhov tsis xws luag thiab cov suab. Qhov siab tshaj plaws forged thaiv qhov ntev yog nyob ntawm cov khoom siv.

Cov Khoom Siv Siv: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 | 42crmo4 | 1.725 | 34Cralni7 | S355j2 | 30nicrmo12 | 22nicrmov

Forged thaiv

Cov xovxwm loj txhaws rau 1500mm X 1500mm seem nrog cov khoom ntev.

Thaiv Forging Devering Deverance feem ntau -0 / + 3mm txog + 10mm nyob ntawm qhov loj me.

Txhua tus hlau muaj cov peev xwm forging los tsim cov kab los ntawm cov hom tshuaj nkaus hauv qab no:

● Alloy Hlau

Spry carbon hlau

● Stainless hlau

Forged thaiv lub peev xwm

Khoom

Max dav

Max hnyav

Carbon, alloy steel

1500 hli

26000 Kgs

Stainless hlau

800mm

20000 kgs

Shanxi Donghuang Cua Zog Hluav Taws Xob Flange Manufacturation Co., Ltd.

Ntaub Ntawv: Tus Qib Hlau C1045

| Tshuaj lom neeg muaj pes tsawg leeg% ntawm cov hlau C1045 (tsis yog G10450) | |||

| C | Mn | P | S |

| 0.42-0.50 | 0.60-0.90 | Max 0.040 | Max 0.050 |

Cov Ntawv Thov

Valve lub cev, hydraulic manifolds, siab rau cov hlab ntsha, mounting blocks, tshuab cuab cov khoom siv, thiab turbine li

Tus Muag Daim Ntawv

Square bar, offset square bar, forged block.

C 1045 forged thaiv

Qhov loj me: W 430 x H 430 x L 1250mm

Forging (Kub Ua Haujlwm) Kev Coj Ua, Cov Txheej Txheem Kho Mob Kub Kub

| Kev zam | 1093-1205 ℃ |

| Ib tug anerting | 778-843 ℃ cua sov cua txias |

| Npau taws | 399-649 ℃ |

| Li no | 871-898 ℃ Cua Txias |

| Austenize | 815-843 ℃ Dej Queny |

| Kev ntxhov siab pab | 552-663 ℃ |

| RM - Tensile Lub Zog (Mpa) (N + t) | 682 |

| RP0.20.2% pov thawj lub zog (mpa) (N + t) | 455 |

| A - Min. elongation ntawm shave (%) (N + t) | 23 |

| Z - Txo hauv ntu hla ntawm pob txha lov (%) (N + t) | 55 |

| Brinell Hardness (HBW): (+ A) | 195 |

Cov Ntaub Ntawv Ntxiv

Thov kom muaj lus hais hnub no

Lossis hu rau: 86-21-52859349

Khoom Qhia:

Phau Ntawv Qhia Yam Khoom Qhia Txog:

Peb yuav tau ua peb tus kheej kom muab peb cov neeg yuav khoom hwm uas siv rau cov kev daws teeb meem zoo tshaj plaws rau 100 tus neeg nyiam Tsis muaj ib qho xwm txheej ploj mus nyob rau ib lub sijhawm tseem ceeb hauv lub sijhawm luv luv, nws yog ib qho yuav tsum rau koj tus kheej ntawm cov zoo heev. Coj los ntawm lub hauv paus ntsiab lus ntawm kev ua siab ceev, kev ua tau zoo, Union thiab kev tsim kho tshiab. Lub lag luam ua rau muaj kev sib zog zoo nthuav dav nws txoj kev lag luam thoob ntiaj teb, nce nws txoj kev lag luam. rofit thiab txhim kho nws cov nplai xa tawm. Peb muaj kev ntseeg siab tias peb yuav muaj lub siab xav thiab faib thoob plaws lub ntiaj teb nyob rau hauv lub xyoo dhau los.

Zoo siab, muaj txiaj ntsig zoo, muaj tswv yim thiab kev ncaj ncees, tsim nyog tau koom tes koom tes! Nrhiav rau pem hauv ntej rau kev koom tes yav tom ntej!