1. isothermal ƙirƙirayana cikin duka tsari na samar da zafin jiki na billet don kula da ƙimar ƙima.Isothermal ƙirƙirashine don yin cikakken amfani da babban filastik na wasu karafa a yanayin zafi guda ɗaya, ko don samun takamaiman ƙayyadaddun ƙayyadaddun abubuwa da kaddarorin. Isothermal ƙirƙira yana buƙatar yawan zafin jiki na mutuwa da billet tare, wanda ke buƙatar tsada mai tsada kuma ana amfani dashi kawaiƙirƙira na musammanmatakai, kamar superplastic forming.

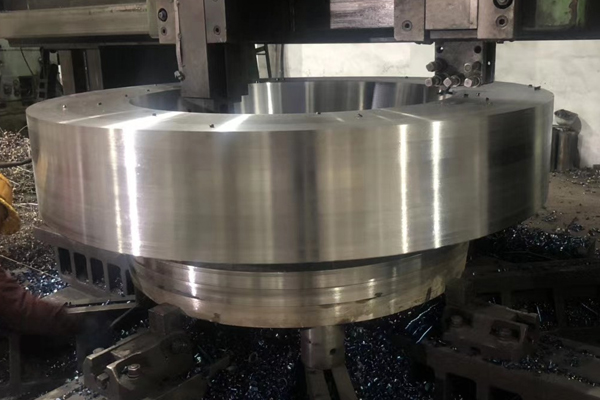

2.ƙirƙirazai iya canza tsarin karfe, inganta aikin karfe. Bayanƙirƙira mai zafi, asali na simintin gyare-gyare, pores, micro-cracks da sauransu an haɗa su ko walda; An karye lu'ulu'u na dendritic na asali kuma hatsi sun zama lafiya. A lokaci guda canza asali carbide rabuwa da m rarraba, sa tsarin uniform, don samun na ciki m, uniform, lafiya, mai kyau m yi, m amfani da ƙirƙira. Bayan zafi ƙirƙira nakasawa, karfe ne fibrous nama; Bayan nakasar ƙirƙira sanyi, lu'ulu'u na ƙarfe suna nuna tsari.

3. ƙirƙirashi ne ya sa karfe filastik ya kwarara kuma ya sanya siffar da ake bukata na workpiece. Ƙarfin ƙarfe yana dawwama bayan kwararar filastik da ƙarfin waje ya haifar, kuma ƙarfe koyaushe yana gudana zuwa sashin tare da ƙarancin juriya. A cikin samarwa, ana sarrafa siffar workpiece sau da yawa bisa ga waɗannan ka'idoji don gane zane mai ban haushi, faɗaɗa rami, lankwasa, zane da sauran nakasawa.

4. ƙirƙiradaga cikin workpiece size ne daidai, m zuwa taro samar kungiyar.Mutu ƙirƙira, extrusion, stamping da sauran aikace-aikace na mold forming size daidai, barga. Ana iya amfani da injunan ƙirƙira ƙirƙira injuna da layin samar da ƙirƙira ta atomatik don tsara ƙwararrun ƙwararrun ƙwararrun ƙwararrun masana'anta ko samar da taro.

5. ƙirƙiratsarin samar da kayayyaki ya haɗa da ƙirƙira blanking billet,ƙirƙiradumama billet da pretreatment kafin kafa; Heat magani, tsaftacewa, calibration da dubawa na workpiece bayan forming. Injunan juzu'i da aka fi amfani da su suna da guduma, latsa ruwa da injin injin. Gudun ƙirƙira yana da babban saurin tasiri, mai dacewa da kwararar filastik ƙarfe, amma zai haifar da girgiza; Na'ura mai aiki da karfin ruwa latsa tare da a tsaye ƙirƙira, shi ne m ga ƙirƙira ta karfe da kuma inganta kungiyar, barga aiki, amma low yawan aiki; Kafaffen bugun bugun inji, mai sauƙin gane injina da sarrafa kansa.

Zuwa gaba,ƙirƙirada fasahar latsawa za su haɓaka don haɓaka ingancin ƙirƙira na ƙirƙira da latsa sassa, haɓaka ƙirƙira ƙirƙira daidaitaccen ƙirƙira da fasaha, haɓaka kayan ƙirƙira da ƙirƙira layin samarwa tare da haɓaka aiki da aiki da kai, haɓaka sassauƙa.ƙirƙirada tsarin latsawa, haɓaka saboƙirƙirakayan daƙirƙirahanyoyin sarrafawa. Don inganta ingancin ciki na ƙirƙira sassa shine yafi inganta kayan aikin injiniya (ƙarfi, filastik, ƙarfi, ƙarfin gajiya) da aminci. Wannan yana buƙatar ingantaccen aikace-aikacen ka'idar lalata filastik ƙarfe; Aikace-aikacen kayan inganci mafi inganci; Daidairiga-kafidumama da ƙirƙira maganin zafi; Ƙarin tsauri da faɗin gwaji mara lahani na sassa masu ƙirƙira.

Lokacin aikawa: Oktoba 18-2021