Kafaffen Gasar Ƙarfin Ƙirar Ƙarya - Ƙirar Sanduna - DHDZ

Kafaffen Gasar Ƙarfin Ƙirar Ƙarya - Ƙirar Sanduna - DHDZ Cikakken Bayani:

Bude Die Forgings Manufacturer A China

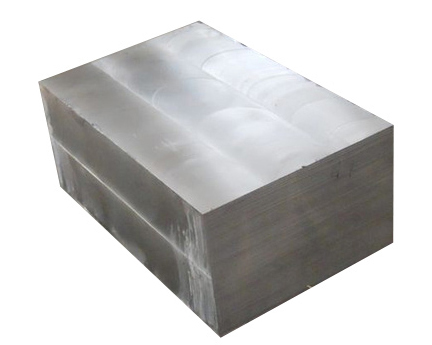

Karɓi Bars

Abubuwan da aka saba amfani da su: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 | 42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30NiCrMo12 | 22NiCrMoV12

RUWAN SIFFOFIN BATSA

Sandunan zagaye, sandunan murabba'i, sandunan lebur da sandunan Hex. All Metals yana da damar ƙirƙira don samar da sanduna daga nau'ikan gami masu zuwa:

● Bakin karfe

● Karfe Karfe

● Bakin karfe

RUBUTUN KARYA

ALOYAYYA

MAX WIDTH

MAX AUNA

Carbon, Alloy

1500mm

26000 kg

Bakin Karfe

800mm

20000 kgs

RUBUTUN KARYA

Matsakaicin tsayin ƙirƙira sanduna zagaye da sanduna hex shine 5000 mm, tare da matsakaicin nauyin 20000 kgs.

Matsakaicin tsayi da faɗi don sandunan lebur da sandunan murabba'i shine 1500mm, tare da matsakaicin nauyin 26000 kgs.

Ana samar da jabun sanda ko sandar birgima ta hanyar ɗaukar ingot da ƙirƙira ta zuwa girman ta, gabaɗaya, falo biyu masu gaba da juna suna mutuwa. Ƙarfashin ƙirƙira yakan zama da ƙarfi, ƙarfi da ɗorewa fiye da simintin simintin gyare-gyare ko sassa na inji. Kuna iya samun ingantaccen tsarin hatsi a cikin duk sassan ƙirƙira, ƙara ƙarfin sassa don jure warping da sawa.

Shanxi DongHuang Wind Power Flange Manufacturing Co., LTD., A matsayin ISO ƙwararren ƙirƙira ƙirƙira, yana ba da garantin cewa jabun da / ko sanduna sun yi kama da inganci kuma ba su da abubuwan da ba su da lahani waɗanda ke da illa ga kaddarorin inji ko kayan aikin injin.

Harka:

Karfe Grade EN 1.4923 X22CrMoV12-1

Tsarin Martensitic

| Abubuwan sinadaran% na karfe X22CrMoV12-1 (1.4923): TS EN 10302-2008 | ||||||||

| C | Si | Mn | Ni | P | S | Cr | Mo | V |

| 0.18 - 0.24 | max 0.5 | 0.4 - 0.9 | 0.3-0.8 | max 0.025 | max 0.015 | 11-12.5 | 0.8-1.2 | 0.25 - 0.35 |

Aikace-aikace

Powerplant, Injin Injiniya, Ƙarfin wutar lantarki.

Abubuwan da aka haɗa don layukan bututu, injin tururi da turbines.

Siffan bayarwa

Wuraren Zagaye, Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙaƙwalwar Ƙaƙwalwa, Ƙarƙashin Ƙarƙashin Ƙarƙashin X22CrMoV12-1

Girman: φ58x536L mm.

Ƙarfafa (Aiki mai zafi) Ƙarfafawa

Ana ɗora kayan aiki a cikin tanderun da kuma zafi. Lokacin da zafin jiki ya kai 1100 ℃, karfe za a ƙirƙira. Yana nufin duk wani tsari na inji wanda ke siffata ƙarfe ta ulilizing ɗaya ko fiye ya mutu, misali buɗaɗɗen ƙirƙira, extrusion, mirgina, da sauransu. Yayin wannan tsari, zafin ƙarfe yana faɗuwa. Lokacin da ya ragu zuwa 850 ℃, karfe zai sake yin zafi. Sa'an nan kuma maimaita aikin zafi a wannan zafin jiki (1100 ℃). Matsakaicin ma'auni don rabon aikin zafi daga ingot zuwa billet shine 3 zuwa 1.

Tsarin Maganin Zafi

Load da kayan aikin gyaran zafin zafin jiki a cikin farar fata. Zafi zuwa zafin jiki na 900 ℃. Rike a zafin jiki na 6 hours 5 minutes. Oil quench da fushi a 640 ℃. Sai Air-sanyi.

Kaddarorin injina na X22CrMoV12-1 ƙirƙira mashaya (1.4923).

| Rm - Ƙarfin ɗaure (MPa) (+QT) | 890 |

| Rp0.20.2% ƙarfin hujja (MPa) (+QT) | 769 |

| KV - Tasirin makamashi (J) (+QT) | -60° 139 |

| A - Min. elongation a karaya (%) (+QT) | 21 |

| Brinell hardness (HBW): (+A) | 298 |

Duk wani maki, ban da wanda aka ambata a sama, ana iya ƙirƙira shi gwargwadon buƙatun abokin ciniki.

Hotuna dalla-dalla samfurin:

Jagoran Samfuri masu dangantaka:

Muna ci gaba da haɓakawa da haɓaka samfuranmu da sabis ɗinmu. A lokaci guda, muna aiki rayayye don yin bincike da ci gaba don Kafaffen Gasar Farashin Forge Bar - Bars Forged - DHDZ , Samfurin zai samar da shi a duk faɗin duniya, kamar: Serbia, Angola, Hungary, Kamfaninmu ya nace akan ka'ida na "Ingantacciyar Farko, Ci gaba mai Dorewa", kuma yana ɗaukar "Kasuwancin Gaskiya, Fa'idodin Mutual" a matsayin burinmu mai tasowa. Duk membobi suna godiya ga duk goyon bayan tsofaffi da sababbin abokan ciniki. Za mu ci gaba da yin aiki tuƙuru tare da ba ku samfurori da sabis mafi inganci.

Wannan kamfani a cikin masana'antar yana da ƙarfi da gasa, yana ci gaba da zamani da haɓaka ci gaba, muna jin daɗin samun damar yin haɗin gwiwa!