I-flat welding flangekanye nokuthengwa kwezinsiza zamapayipi akuhlukaniseki. Namuhla, ngizokwethula ama-flange welding flat ngokuningiliziwe, ukuze amakhasimende aqonde kangcono ama-flange welding flat, ukuze kube lula ukuthenga.

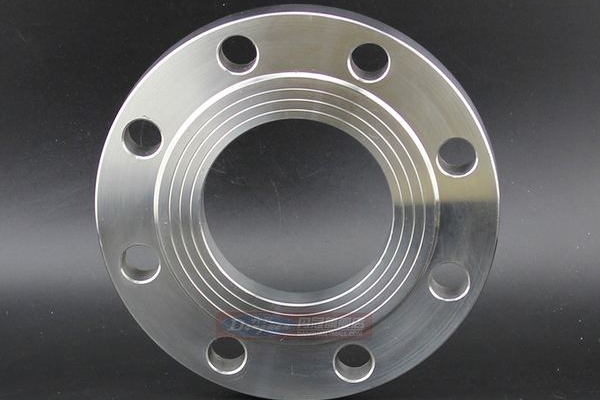

A: flat Welding flangeibhekisela ku-ai-flangeexhunywe nesitsha noma ipayipi nge-fillet welding. Kuyi-flange engafanele. Hlola okubalulekilei-flangenoma okuxekethilei-flangengokobuqotho bei-flangeindandatho nesigaba sepayipi eqondile ngesikhathi sokuklama. Kunezinhlobo ezimbili zei-flangeamasongo anentamo nangaphandle. Uma kuqhathaniswa neintamo isinqe welding flange, i-flange ye-welding eyisicaba ilula ngesakhiwo futhi ilondoloza izinto ezibonakalayo, kodwa ukuqina nokubekwa uphawu akukuhle njenge-neck butt welding flange. Ama-flange welded flange asetshenziswa kabanzi ukuxhuma imikhumbi yokucindezela okuphakathi nendawo kanye namapayipi.

Okubili: izici zeflat Welding flange: flat Welding flangeokungenani ingasindisa isikhala futhi inciphise isisindo, okubaluleke nakakhulu, ukuqinisekisa ukuthi ukujoyina ngeke kuvuze futhi kube nokusebenza okuhle kokuvala. Ngakho-ke, ama-flange gaskets athathelwe indawo ngamasongo okuvala ukuze kuqinisekiswe ukuthi indawo yokuvala ifana nendawo yokuvala. Ngale ndlela, kuphela inani elincane lokucindezela elidingekayo ukuze ucindezele isivalo se-seal. Ukuze kuncishiswe ukuncishiswa kwengcindezi edingekayo, ubukhulu nenani lamabhawodi lingahlukaniswa ngokufanele, ngakho umphumela uba umkhiqizo omusha omncane ngosayizi nokukhanya ngesisindo (amaphesenti angama-70 kuya kwangu-80 alula kunama-flange avamile). Ngakho-ke,flat Welding flangeiyikhwalithi ephezulu uma kuqhathaniswaflat Welding flangeimikhiqizo, inciphisa izinga nesikhala, futhi idlala indima ebalulekile ekusetshenzisweni kwezimboni.

Ezintathu:flat Welding flangeumgomo wokuvala: izindawo ezimbili zokuvala amabhawodi zikhama i-gasket ye-flange futhi zenze uphawu, okuholela ekubhujisweni kophawu. Ukuze kugcinwe uphawu, amandla amakhulu ebhawodi kufanele agcinwe. Ngakho-ke, i-bolt kufanele yenziwe ibe ububanzi. Ubukhulu bebhawodi budinga ukuhambisana nobubanzi bentongomane, okusho ukuthi ububanzi bebhawodi buyadingeka ukuze kwakhiwe izimo ezisetshenziselwa ukuqinisa nati. Kodwa-ke, ububanzi nosayizi wamabhawodi, indlela esebenzayo kanye nakho konke ukufakwa kuzodinga ubukhulu obukhulu nesisindo. Lokhu kudala inkinga ethile endaweni yaseMarine, lapho isisindo sihlala siyinkinga enkulu umuntu okufanele akuqaphele. Futhi, ngokuyisisekelo, ama-flange ashiselwe ayisicaba ayizimpawu ezingasebenzi. I-50% yomthwalo we-bolt iyadingeka ukuze isetshenziswe njenge-gasket ye-extrusion, kuyilapho kuphela i-50% yomthwalo edingekayo ukuze kugcinwe ingcindezi.

Ama-flange ashiselwealungele amasistimu amapayipi anamazinga okucindezela aphansi kanye nokuguquguquka okuncane kwengcindezi, ukudlidliza nokushaqeka. Ama-flange we-welded anenzuzo yokuthi kulula ukuvumelanisa ngesikhathi sokushisela nokuhlanganisa futhi angabizi kakhulu, ngakho-ke asetshenziswe kabanzi.

Isikhathi sokuthumela: Dec-30-2021