1. Isothermal forgingukugcina izinga lokushisa le-billet lingashintshi phakathi nayo yonke inqubo yokwakha.Isothermal forgingisetshenziselwa ukusizakala nge-plasticity ephezulu yezinsimbi ezithile ekushiseni okungashintshi noma ukuthola izakhiwo nezakhiwo ezithile. I-Isothermal forging idinga ukuthi isikhunta kanye ne-billet kugcinwe ezingeni lokushisa elingapheli ndawonye, okudinga izindleko eziphezulu futhi kusetshenziselwa kuphela izinqubo ezikhethekile zokukhanga nokucindezela, njengokubunjwa kwe-superplastic.

2. Ukuqambaingashintsha isakhiwo sensimbi futhi ithuthukise ukusebenza kwensimbi. Ngemvaukuganga okushisayoingot, isimo sokuqala sabalingisi sokuxega, imbotshana, i-micro crack ihlanganiswe noma ishiselwe; Ikristalu ye-dendritic yasekuqaleni iphukile ukwenza okusanhlamvu kube kuhle. Ngasikhathi sinye, shintsha ukuhlukaniswa kwe-carbide yasekuqaleni kanye nokusabalalisa okungalingani, ukuze inhlangano ifane, ukuze uthole okuminyene kwangaphakathi, umfaniswano, okuhle, ukusebenza kahle okuphelele, ukusetshenziswa okuthembekile kwe-forgings. Ngemvaukuganga okushisayodeformation, insimbi isakhiwo fibrous; Ngemuva kokuguqulwa okubandayo kokubumba, amakristalu ensimbi akhombisa ukuhleleka.

3.ukuqambaukwenza ipulasitiki yensimbi igeleze futhi yenziwe ibe yisimo oyifunayo se-workpiece. Umthamo wensimbi awushintshile ngemva kokugeleza kwepulasitiki ngamandla angaphandle, futhi insimbi ihlale igeleza engxenyeni yokumelana okuncane. Ekukhiqizeni, ukuma kwe-workpiece kuvame ukulawulwa ngokwale mithetho, futhi ukuguqulwa komdwebo ocasulayo, ukubuyisela kabusha, ukugoba nokudweba okujulile kuyabonakala.

4.iumsebenzi wokwakhaubukhulu bunembile, buhambisana nenhlangano yokukhiqiza ngobuningi.Ukufa ngokukhohlisa, i-extrusion, isitembu nezinye izinhlelo zokusebenza zosayizi wokwenza isikhunta zinembile futhi zizinzile. Imishini yokukhanga esebenza kahle kakhulu kanye nolayini wokukhiqiza wokubumba othomathikhi ungasetshenziswa ukuhlela ukukhiqizwa kwenqwaba okukhethekile noma ukukhiqizwa ngobuningi.

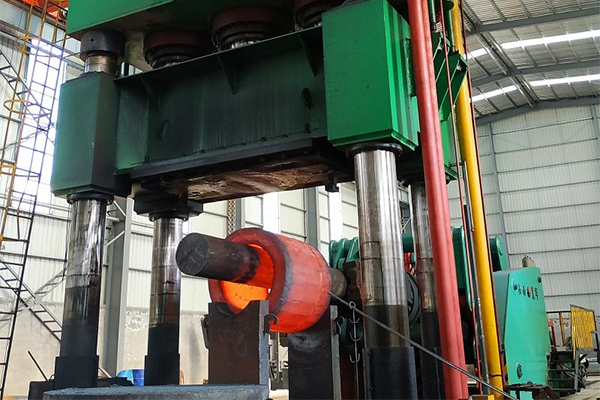

5.Inqubo yokukhiqiza yeukuqambakuhlanganisa ukuvala, ukufudumeza kanye nokwelashwa kwangaphambili kokufogetha kungenalutho ngaphambi kokwakheka; Ukwelashwa kokushisa, ukuhlanza, ukulinganisa nokuhlolwa kwe-workpiece ngemva kokwakhiwa. Imishini yokubumba esetshenziswa kakhulu inesando sokubumba, i-hydraulic press kanye nomshini wokunyathelisa. Isando sokwakha sinesivinini esikhulu somthelela, esivumela ukugeleza kwepulasitiki yensimbi, kodwa sizokhiqiza ukudlidliza; Umshini wokunyathelisa we-hydraulic usebenzisa i-static forging, kunenzuzo ekwenzeni ngensimbi kanye nenhlangano yokuthuthukisa, umsebenzi uzinzile, kodwa ukukhiqiza kuphansi; Umshini wokunyathelisa une-stroke engaguquki, okulula ukuyibona umakhenikha ne-automation.

Esikhathini esizayo, i-ubuchwepheshe bokuqambaizothuthukisa ikhwalithi yangaphakathi yeizingxenye zokuqamba, thuthukisa ukunembaukuqambakanye nobuchwepheshe bokugxiviza ngokunemba, thuthukisaimishini yokuqambafuthiukukhiqizwa kokuqambaihambisane nokukhiqiza okuphezulu kanye neziqu ze-automation, thuthukisaukukhwabanisa okuguquguqukayoukwakha uhlelo, futhi kuthuthukiswe entshaizinto zokwakhafuthiukuqopha ukucubungulaizindlela. Ukuthuthukisa ikhwalithi yangaphakathi yeama-forgings, ikakhulukazi ukuthuthukisa izakhiwo zabo zemishini (amandla, ipulasitiki, ukuqina, amandla okukhathala) nokuthembeka. Lokhu kudinga ukusetshenziswa okungcono kwe-metal plastic deformation theory; Sebenzisa izinto ezisezingeni elingcono kakhulu; Ukushisa okulungile kwangaphambi kokubumba kanye nokwelashwa kokushisa kokubumba; Ukuhlolwa okuqinile nokubanzi okungabhubhisi kwe-forgings.

Isikhathi sokuthumela: Jan-25-2021