Iizinto zokwakhaikakhulukazi i-carbon steel ne-alloy steel, ilandelwa i-aluminium, i-magnesium, ithusi, i-titanium nama-alloys ayo. Isimo sangempela sento i-bar, ingot, impushana yensimbi nensimbi ewuketshezi. Isilinganiso sendawo ye-cross-sectional yensimbi ngaphambi nangemva kokuguqulwa kubizwa ngokuthiukubunjwa isilinganiso. Ukukhetha okulungile kweukubunjwa isilinganiso, izinga lokushisa elifanele lokushisisa kanye nesikhathi sokubamba, izinga lokushisa lokukhanga elifanele kanye nezinga lokushisa lokugcina lokubumba, inani elizwakalayo lokuguga kanye nesivinini sokuguga kunethonya elikhulu ekuthuthukiseni ikhwalithi yomkhiqizo nokunciphisa izindleko.

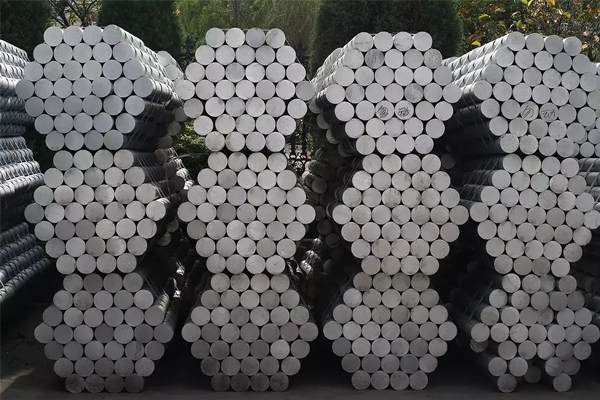

Okujwayelekile okuncane futhiama-forging aphakathiamabha ayindilinga noma ayizikwele njengamabhilidi. Imigoqo inesakhiwo sokusanhlamvu esifanayo kanye nezakhiwo ezinhle zemishini, ukuma okunembile nosayizi, ikhwalithi enhle yendawo, elungele ukukhiqizwa ngobuningi. Inqobo nje uma izinga lokushisa lokushisa kanye nezimo ze-deformation zilawulwa ngokunengqondo, kuhleama-forgingsingakhiwa ngaphandleukukhwabanisa okukhuluukuguquguquka.

I-Ingot isetshenziselwa kuphelaama-forging amakhulu. Ingot iyisakhiwo se-as-cast esinamakristalu amakhulu amakholomu nezikhungo ezixekethile. Ngakho-ke, amakristalu ekholomu kufanele aphulwe abe yizinhlamvu ezinhle ngokusebenzisa i-deformation enkulu yepulasitiki, futhi ukuhlanganisa okuxekethile kungathola isakhiwo sensimbi esihle kakhulu kanye nezakhiwo zemishini.

Ukwenziwa kwempushana kungenziwa kusuka ku-pre- made powder metallurgy preforms ngemuva kokucindezelwa nokudubula ngaphansi kwesimo esishisayokufa ukukhohlisangaphandle kokubhakuzisa.Forgingsimpushana iseduze nokuminyana kokujwayelekileama-forgings afe, enezici ezinhle zemishini nokunemba okuphezulu, okunganciphisa ukusika okulandelayo. Ama-powder forging anesakhiwo sangaphakathi esifanayo futhi akukho ukuhlukaniswa okungasetshenziswa ukwenza amagiya amancane nezinye izinto zokusebenza. Kodwa-ke, intengo ye-powder iphakeme kakhulu kunebha evamile, ngakho-ke ukusetshenziswa kwayo ekukhiqizeni kunomkhawulo. ,

Umumo oyifunayo kanye nezakhiwo zeama-forgings afeingatholakala ngokusebenzisa ukucindezela okumile ensimbi ewuketshezi ethela ekamelweni lokufa ukuze iyenze iqine, icwebezele, igeleze, i-deformation yepulasitiki kanye nefomu ngaphansi kwesenzo sokucindezela. I-Liquid metal die forging iyindlela yokwakha phakathi kwe-die casting kanye ne-die forging, ifaneleka kakhulu izingxenye eziyinkimbinkimbi ezinodonga oluqinile okunzima ukuzenza ngokujwayelekile.kufa ukukhohlisa.

Ukuqambaizinto zokwakha ngaphezu kwezinto ezijwayelekile, njengokwakheka okuhlukahlukene kwe-carbon steel ne-alloy steel, kulandelwa i-aluminium, i-magnesium, ithusi, i-titanium nama-alloys ayo, izinga lokushisa eliphakeme lensimbi eyisisekelo ingxubevange, i-nickel base superalloy, i-cobalt-based superalloy deformation ye-alloy futhi ISEBENZISA indlela yokubumba noma yokugoqa, ingxubevange kuphela ngenxa yendawo yayo encane yepulasitiki.ukuqambaUbunzima buyoba bukhulu kakhulu, Izinga lokushisa elihlukile lezinto zokushisa, izinga lokushisa elivulekile lokubumba kanye nokushisa kokugcina lokubumba kunezidingo eziqinile.

Isikhathi sokuthumela: Mar-14-2022