Ngenxa yezindleko eziphakeme zezinto zokusetshenziswa ezinkuluama-forgings, kanye nenqubo yokukhiqiza, uma kwenzeka amaphutha, azothinta ukucubungula okulandelwayo noma ikhwalithi yokucubungula engalungile, futhi ezinye zithinta ukusebenza nokusetshenziswa kwe-forgings ngokuqinile, ngisho nokunciphisa impilo yesevisi yezingxenye eziqediwe, kubeka engcupheni ukuphepha. Ngakho-ke, ukuze kuqinisekiswe noma kuthuthukiswe izinga leama-forging amakhulu, ngaphezu kokuqinisa ukulawulwa kwekhwalithi kule nqubo, thatha izinyathelo ezifanele zokuqeda ukuvela kweukuqambaamaphutha, kodwa futhi kufanele enze ukuhlolwa kwekhwalithi okudingekayo, ukuvimbela inqubo elandelayo enomthelela omubi ekusebenzeni kokukhubazekaama-forgingsukugeleza kunqubo elandelayo. Ngemva kokuhlolwa kwekhwalithi, izinyathelo zokulungisa zingase futhi zithathwe ezingxenyeni ezifojiwe ngokuvumelana nemvelo yeziphambeko kanye nezinga lethonya ekusetshenzisweni, ukuze zihlangabezane nezindinganiso zobuchwepheshe noma izidingo zokusetshenziswa.

Ngakho-ke, ukuhlolwa kwekhwalithi ye-forgings ngomqondo othile, uhlangothi olulodwa ukulawula ikhwalithi ye-forgings yenziwe, ngakolunye uhlangothi ukukhomba isiqondiso sokuthuthukiswa kwenqubo yokubumba, ukuze kuqinisekiswe ukuthi ikhwalithi ye-forgings ihlangabezana nezidingo zezindinganiso zobuchwepheshe bokukhanga, futhi ihlangabezane nezidingo zokuklama, ukucubungula nokusetshenziswa.

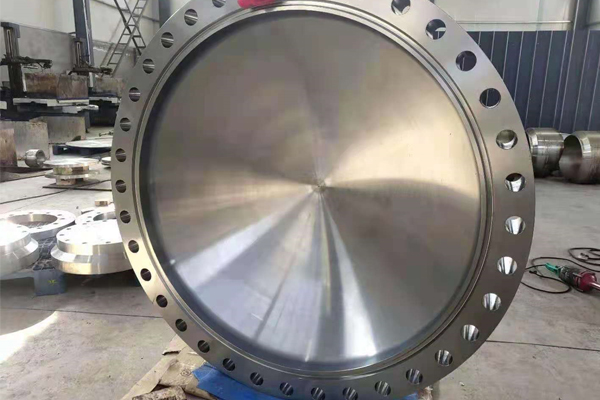

Ukuhlolwa kwekhwalithi yama-forging amakhulu kufaka phakathi ukuhlolwa kwekhwalithi yokubukeka kanye nekhwalithi yangaphakathi. Ukuhlolwa kwekhwalithi yokubukeka ikakhulukazi kubhekisela ekuhlolweni kosayizi wejiyomethri, ukwakheka, isimo sendawo engaphezulu nezinye izinto zokubumba; Ukuhlolwa kwekhwalithi yangaphakathi ngokuyinhloko kubhekisela ekuhlolweni kokwakheka kwamakhemikhali, ukwakheka okukhulu, ukwakheka kwe-microscopic kanye nezakhiwo zemishini ze-forgings.

Ngenxa yokuthiama-forgingsizingxenye ezenziwe, ukusatshalaliswa kokucindezeleka ngesikhathi sokusetshenziswa, idigri ebalulekile, isimo sokusebenza sihlukile, izinto zayo kanye nenqubo ye-metallurgy ihlukile, ngakho-ke umnyango ohlukene ngokusekelwe kulesi simo esingenhla futhi ngokuvumelana nezidingo zalo mnyango wamazwe ngamazwe uzokwakha izigaba ezihlukene, iminyango ehlukene, amazinga ahlukene okuhlukaniswaama-forgingsnazo zihlukile. Kunoma yikuphi, ukuhlolwa kwekhwalithi ye-forgings enkulu iyonke ayinakuhlukaniswa nezigaba ezimbili zokuhlola, okungukuthi, ukuhlolwa kwekhwalithi yokubukeka nekhwalithi yangaphakathi, kodwa izinhlobo zeama-forgingszihlukile, futhi izinto ezithile zokuhlola, inani lokuhlola kanye nezidingo zokuhlola zihlukile. Isibonelo, eminye iminyango yezimboni izoba yinsimbi yesakhiwo, insimbi engagqwali, insimbi engashisiama-forgingsekilasini le-IV ukuze lihlolwe, eminye iminyango izoba yi-aluminium alloy forgings kanye ne-die forgings ngokusho kokusetshenziswa kwayo ekilasini ukuze ihlolwe, kanti eminye iminyango izoba yi-aluminium alloy, i-alloy forgings yensimbi ibe yikilasi le-IV ukuze lihlolwe.

Isikhathi sokuthumela: Aug-04-2021