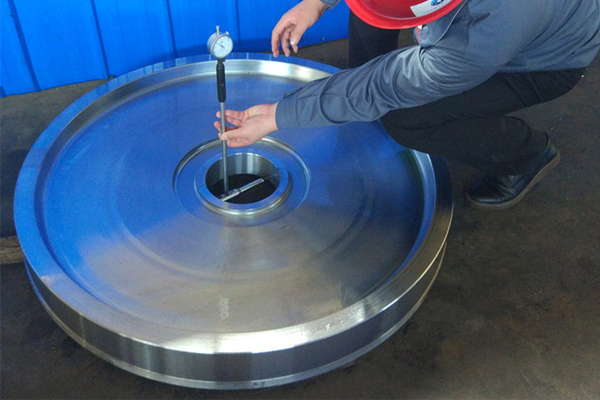

Ukuhlolwa kwekhwalithi yokubukeka ngokuvamile kuwukuhlola ongonakali, ngokuvamile ngeso lenyama noma ukuhlola ingilazi ekhulisayo ephansi, uma kunesidingo, futhi sebenzisa indlela yokuhlola engacekeli phansi.

Izindlela zokuhlola ikhwalithi yangaphakathi yeforgings ezinzimakungafingqwa njengokuthi: ukuhlolwa kwenhlangano enkulu, ukuhlolwa kwenhlangano emincane, ukuhlolwa kwezakhiwo zemishini, ukuhlaziya ukwakheka kwamakhemikhali nokuhlola okungabhubhisi.

Ukuhlolwa kwe-microstructure ye-macroscopic kuwuhlobo lokuhlola ukubuka nokuhlaziya izici ze-microstructure enamandla aphansiukuqambangengilazi yokukhulisa amandla ebonakalayo noma enamandla aphansi. Izindlela ezivame ukusetshenziswa zokuhlolwa kwesakhiwo esikhulu seama-forgingsizindlela zokugqwala zamandla aphansi (okuhlanganisa ukugqwala okushisayo, ukugqwala okubandayo kanye nendlela yokugqwala kwe-electrolytic), ukuhlolwa kokuphuka kanye nendlela yokuphrinta isulfure.

Umthetho wokuhlolwa kwe-Microstructure ukusebenzisa isibonakhulu esikhanyayo ukuhlola ukwakheka kwe-microstructureama-forgingszezinto ezihlukahlukene. Izinto zokuhlola ngokuvamile zihlanganisa usayizi wokusanhlamvu wangaphakathi, noma usayizi wokusanhlamvu ezingeni lokushisa elishiwo, okungukuthi usayizi wangempela wokusanhlamvu, ukufakwa okungeyona insimbi, i-microstructure efana ne-decarburization layer, i-eutectic carbide inhomogeneity, ukushisa ngokweqile, ukushiswa ngokweqile kanye nezinye izakhiwo ezincane ezidingekayo, njll.

Izakhiwo zemishini kanye nokuhlolwa kokusebenza kwenqubo kufanele kube ukwelapha kokugcina kokushisa kweama-forgingskanye nezingcezu zokuhlola ezicutshungulwe zaba isampula elishiwo ngemva kokusetshenziswa komshini wokuhlola oqinile, umshini wokuhlola umthelela, umshini wokuhlola ukukhuthazela, umshini wokuhlola ukukhathala, umhloli wokuqina nezinye izinsimbi zokunquma izakhiwo zemishini kanye nokucubungula amanani okusebenza.

Ukuhlolwa kokwakheka kwamakhemikhali ngokuvamile kuwukusetshenziswa kokuhlaziywa kwamakhemikhali noma ukuhlaziya okubonwayo kokuhlaziywa nokuhlolwa kwezingxenye ezikhangayo, ngokuthuthukiswa kwesayensi nobuchwepheshe, kokubili ukuhlaziywa kwamakhemikhali kanye nokuhlaziywa kwe-spectral kwezindlela zokuhlaziya kwenze inqubekelaphambili. Ukuhlaziywa kwe-spectral, manje akusebenzi nje indlela ye-spectral kanye nendlela ye-spectroscopic ukwenza ukuhlaziywa kwengxenye, ukuvela kwe-spectrometer ye-photoelectric hhayi nje ukuhlaziya okusheshayo, kodwa futhi kuthuthukisa kakhulu ukunemba, nokuvela kwe-plasma photoelectric spectrometer kuye kwathuthukisa kakhulu ukunemba kokuhlaziywa, ukunemba kokuhlaziywa kwayo kufinyelela ezingeni eliyingozi 10-ndlela yokuhlaziya kufinyelela ku-10. Pb, As, Sn, Sb, Bi in superalloy forgings.

Okushiwo ngenhla, indlela yokuhlola, ukuhlelwa kwe-macroscopic, kanye nokwakheka kanye nokuhlolwa kwe-microstructure noma ukusebenza noma indlela, konke kungokwendlela yokuhlola elimazayo, ngoba ezinye izindlela ezisindayo zezindlela ezilimazayo azikwazi ukuzivumelanisa ngokuphelele nemfuneko yokuhlolwa kwekhwalithi, ngakolunye uhlangothi, lokhu kungenxa yokuthi akuwona umnotho, ngakolunye uhlangothi ikakhulukazi ukugwema uhlangothi olulodwa lokuhlola okulimazayo. Ukuthuthukiswa kobuchwepheshe be-NDT kunikeza izindlela ezithuthuke kakhulu nezipheleleukuqambaukuhlolwa kwekhwalithi.

Izindlela zokuhlola ezingonakali zokuhlola ikhwalithi ngokujwayelekile yilezi: indlela yokuhlola impushana kazibuthe, indlela yokuhlola ukungena, indlela yokuhlola yamanje ye-eddy, indlela yokuhlola i-ultrasonic.

Indlela yokuhlola izinhlayiya kazibuthe isetshenziswa kabanzi ukuhlola indawo engaphezulu noma eduze nokukhubazeka kwensimbi ye-ferromagnetic noma ingxubevange.ama-forgings, njengokuqhekeka, imibimbi, amabala amhlophe, okungafakwanga kwensimbi, i-delamination, ukugoqa, amabhande e-carbide noma ama-ferritic, njll. Le ndlela ifaneleka kuphela ukuhlolwa kwe-ferromagnetic.ama-forgings, kodwa hhayi okokwakha okwenziwe ngensimbi ye-austenitic.

Indlela yokuhlola ye-Penetrant ayikwazi nje ukuhlola izinto ezisetshenziswayo kazibuthe, kodwa futhi ihlole ukukhubazeka okungaphezulu kwezinto ezingezona i-ferromagnetic.ama-forgings, njengokuqhekeka, ukuxega, ukugoqa, njll. Ngokuvamile, isetshenziswa kuphela ukuhlola ukonakala okungaphezulu kwezinto ezingezona ze-ferromagnetic, futhi ayikwazi ukuthola izici ezifihliwe ngaphansi kwendawo. Ukuhlolwa kwamanje kwe-Eddy kusetshenziselwa ukuhlola amaphutha angaphezulu noma aseduze kwezinto ezisetshenziswayo.

Indlela yokuhlola ye-Ultrasonic isetshenziselwa ukuhlola ukukhubazeka kwangaphakathi kwe-forgings njenge-shrinkage cavity, indawo emhlophe, i-core crack, ukufakwa kwe-slag, njll Nakuba le ndlela ilula, ishesha futhi iyonga, kunzima ukucacisa ngokunembile uhlobo lweziphambeko.

Isikhathi sokuthumela: Nov-17-2021