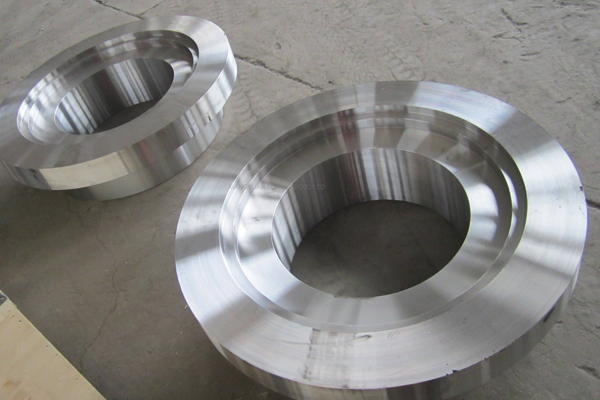

Amathuluzi nezinto zokusebenza ezisetshenziselwa ukufoja mahhala zilula, ziyabiza futhi ziphansi. Uma kuqhathaniswa nokulingisa okungenalutho,mahhala ukuqambaiqeda i-shrinkage cavity, i-shrinkage porosity, i-porosity nezinye iziphambeko, ukuze okungenalutho kube nezakhiwo eziphezulu zemishini.Forgingszilula ngokuma futhi ziyavumelana nezimo ekusebenzeni. Ngakho-ke, kubaluleke kakhulu ekwakhiweni kwemishini esindayo nezingxenye ezibalulekile.

Inkambu yohlelo lokusebenza

Ama-forgings wamahhalakulawulwa ukusebenza okwenziwa ngesandla komumo nosayizi weama-forgings, ngakho-keukwenza ukunembaiphansi, isibonelelo sokucubungula sikhulu, umfutho wabasebenzi mkhulu, ukukhiqiza awuphezulu, ngakho-ke isetshenziswa kakhulu ekukhiqizeni iqoqo elilodwa, elincane.

1) Usayizi we-billet kanye nosayizi omaphakathi kufanele uhambisane nezindawo zokusebenza zenqubo ngayinye, njengesilinganiso sobude bobubanzi (H/D) bezinto ngaphambi kokucasula ngu-2-2.5, kanye nedatha yokwaziswa yokuguqulwa kwesigaba lapho udweba.

2) kuyadingeka ukulinganisa ukuguqulwa kosayizi ongenalutho ku-ukwenza izinqubo,isibonelo, ubude obungenalutho buncishiswa lapho kushaywa, ngokuvamile izikhathi ezingu-1.1 zobude bokufogela; Lapho ukuphakama kwe-core shaft reaming kuyanda.

3) ukuhlehlisa kwesigaba, kufanele kuqinisekise ukuthi ingxenye ngayinye yokufoja inevolumu eyanele, njengakushafti wesinyathelo, i-crankshaft noma i-gear boss billet, yenza umsebenzi omuhle wokusabalalisa ivolumu yengxenye ngayinye.

4) Niniukuqambangemililo eminingi, kufanele kuqashelwe ukuthi kungenzeka yini ukushisa umlilo ngamunye phakathi. Uma iama-forgingszidonswa isikhathi eside kakhulu ekuqaleni, usayizi wesithando somlilo akwanele ukufaka ama-forging amade ngesikhathi sokushisa kwesibili. Ukuze kuqinisekiswe usayizi kanye nekhwalithi ye-forging, ukunakwa okukhethekile kufanele kukhokhwe ekuguqulweni komlilo ngemuva kuka-Z kanye nokulawulwa kwezinga lokushisa lokuqala nelokugcina ngemuva kuka-Z.

5) Kuyadingeka ukuqinisekisa ukuthi kunesibonelelo esanele sokunquma ngemuva kokuqeda u-Z, futhi kufanele kuqashelwe:

(1) Ngoba ngesikhathi sokucindezela ihlombe, ukugudluzwa, ukubhoboza nokunye, kukhona isenzakalo sokudweba nokuncipha endaweni engenalutho, okufanele ishiye imali yokugqoka phakathi nenqubo ephakathi;

(2) Ukwakha isikhathi esideama-shaft forgings(njengama-crankshafts, njll.) kanyeama-forgingsngamabhulokhi we-concave, ngoba usayizi wabo wobude awukwazi ukucasuka futhi, kufanele kulinganiselwa ukuthi ubukhulu besiqondiso sobude buzonwetshwa kancane ekugqokeni futhi buholele ekubekezeleleni ngaphandle kokubekezelelana.

Ukuqamba.

6) Lapho ukhetha amathuluzi, izingane kufanele zisebenzise amathuluzi ajwayelekile. Uma iqoqo lokukhiqiza lilikhulu, amathuluzi akhethekile noma isikhunta samathayi singenziwa ukuze kuthuthukiswe ikhwalithi kanye nokuphumayo kokubunjwa.

7) Ngokuya ngosayizi kanye nekhwalithi yokungenalutho, khetha imishini ekhona ku-workshop.

Isikhathi sokuthumela: Dec-15-2021