I-flat welding flangengokwentando yakhoukuqambadie ukunyakaza, ingahlukaniswa jika rolling, swing rotaryukuqamba, ukubumba amasondo, ukugingqika, ukugoqa indandatho, ukugoqa nokunye. Ukubumba okunembayo nakho kungasetshenziswa ekujikiseni ukushwibeka, ukufoja okuzungezayo nokugingqika. I-roll forging kanye ne-cross rolling ingasetshenziswa njengokwelashwa kwangaphambili kwezinto ezizacile ukuze kuthuthukiswe ukusetshenziswa kwezinto. Njengokufoja kwamahhala, i-rotary forging yakheka kancane futhi inenzuzo yokwenza ngisho noma amandla okubumba engaphansi kosayizi wokubumba. Ama-forging ayinkimbinkimbi angaqedwa ngenqubo eyodwa noma ngaphezulu. Ngenxa yokuthi awekho ama-burr edges, indawo yokuzala iyancishiswa futhi umthwalo odingekayo uyancishiswa.

Lokhuukuqambaindlela ibangela ukuthi impahla inwebe isuka eduze ne-flange lapho yenziwa ngomshini. Ngenxa yokuthi ibanga phakathi kwendawo yokufa nendawo yamahhala lihlukile, kunzima ukuqinisekisa ukunemba. Ngakho-ke, ngokulawula isiqondiso sokunyakaza kwe-forging die kanye nenqubo ye-rotary forging ngekhompyutha, imikhiqizo enomumo oyinkimbinkimbi nokunemba okuphezulu ingakhiqizwa. Yebo, ngingakwenza. Kutholwe ngamandla aphansi okuqamba. Ama-Steam turbine blades nezinye izinhlobo nosayizi omkhuluama-forgingsukukhiqiza.

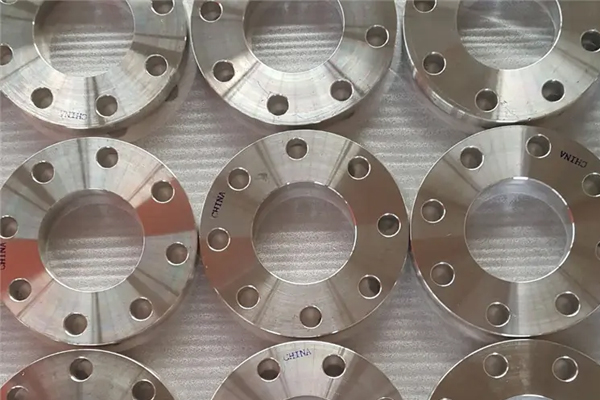

I-flat welding flange ukuqambaingahlukaniswa ibe mahhalaukuqamba, ukucasula, i-extrusion, i-die forging, i-defaging evaliwe kanye nokuqamba okucasulayo okuvaliwe. Ngokuvamile, ukubumba ebangeni lokushisa le-recrystallization kubizwa ngokuthi i-hot forging, ekamelweni lokushisa ngaphandle kokufudumeza ukubumba kubizwa ngokuthi i-cold forging. Niniamaflange ashiselwe flatkukhonaumgunyathiat lokushisa low, izilinganiso theama-forgingsneze ukushintsha. Uma yenziwe ngaphansi kuka-700 ℃, cishe asikho isikali se-oxide esakhiweyo futhi akukho kususwa kwe-surface decarburization okwenzekayo.

I-flat welding flangeumgomo wokuvala: izindawo ezimbili zokuvala amabhawodi zicindezela ku-gasket ye-flange ukwenza uphawu, okungase futhi kuholele ekulimaleni kokuvalwa. Ukuze kugcinwe uphawu, kuyadingeka ukugcina amandla amakhulu e-bolt, ngakho-ke ukwandisa i-bolt. Amabhawodi amakhulu kufanele afane namantongomane amakhulu. Lokhu kusho ukuthi uzodinga amabhawodi amakhulu ukuze udale izimo zokuqinisa inati.

Inothi leflat Welding flange

1. Ipuleti lensimbi elisetshenziselwa ukwakhaamaflange ashiselwe flatikhiqizwa futhi isetshenziswe ngokuhlolwa kwe-ultrasonic ngaphandle kwe-delamination, ukuze kutholakale izinkinga ezinhle zekhwalithi nokusebenza, futhi kwenziwe futhi kuhlolwe ngokuvumelana nezidingo ezithile zekhwalithi, ipuleti yensimbi ayinayo izinkinga zekhwalithi.

2. Insimbi isikwa ibe yimichilo eduze nendawo eginqikayo, bese igotshwa futhi izinqe zishiselwa zibe izindandatho, zenze indawo eyindilinga phezu kwensimbi. Isilinda. Ekwenzeni ama-flanges ane-welded flat, ipuleti yensimbi akufanele ifakwe ngokuqondile ku-flange yentamo, kodwa kunalokho ikhiqizwa futhi yenziwe ngomshini kusetshenziswa inqubo ethile.

Isikhathi sokuthumela: Jun-13-2022