Ngokusho kwejubane lokupholisa elihlukile, kunezindlela ezintathu zokupholisa ze-stainlessizinsimbi zensimbi: ukupholisa emoyeni, isivinini sokupholisa siyashesha; Ijubane lokupholisa lihamba kancane esihlabathini; Ukupholisa esithandweni, izinga lokupholisa lihamba kancane.

1. Ukupholisa emoyeni. Ngemvaukuqamba, engenabalaizinsimbi zensimbizibekwe ngokuqondile phansi endaweni yokusebenzela ukuze zipholise zibe yizicucu ezilodwa noma zibe yinqwaba, kodwa hhayi emhlabathini omanzi noma ipuleti lensimbi, noma endaweni edonsa amanzi, ukuze kugwenywe ukupholisa okungalingani noma ukupholisa okusheshayo kwendawo okubangela imifantu.

2. Ukupholisa emgodini womlotha owomile nomgodi wesihlabathi (ibhokisi), izinga lokushisa elijwayelekile lesihlabathi sensimbi akufanele libe ngaphansi kuka-500℃, umlotha ozungezile nesihlabathi ukujiya asikho ngaphansi kuka-80mm.

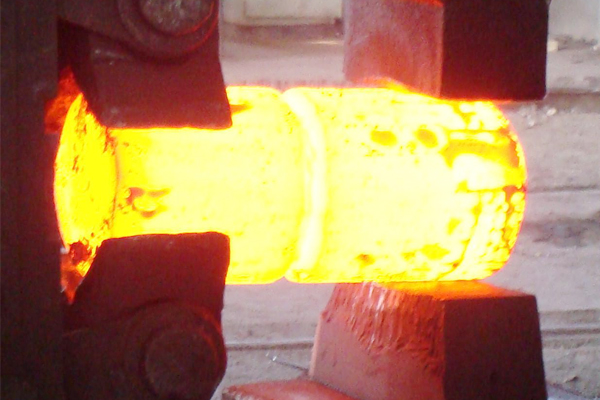

3. Ukupholisa esithandweni, ngaphandle kwebalaizinsimbi zensimbizifakwa ngqo esithandweni ukuze zizipholise ngemva kokufoja. Izinga lokushisa lezingxenye zensimbi esithandweni somlilo akufanele libe ngaphansi kuka-600-650 ℃, futhi izinga lokushisa lensimbi engenasici esithandweni somlilo lilingana nalelo lesithando somlilo. Ngenxa yokuthi izinga lokupholisa lezinsimbi zensimbi engagqwali lingalawulwa ngokulungiswa kwezinga lokushisa kwesithando somlilo, lifanele ukupholisa kwangemva kokupholisa kwensimbi ye-alloy ephezulu, izinsimbi ezikhethekile ze-alloy steel forgings nezinsimbi ezinkulu ezingenasici.

Ingenabalaizinsimbi zensimbiIzindlela zokushisa ze-induction surface zinezinhlobo ezimbili: iselula eqhubekayo futhi engaguquki, indlela eqhubekayo ehambayo inzwa noma i-stainless steel forgings ukushisa nokuhamba ngenqubo yokupholisa nokucisha okulandelwa unqenqema. Futhi fixed ibalaizinsimbi zensimbiindawo yokushisisa yokucisha inzwa, inzwa nensimbi engagqwali forgings akukho ukunyakaza okuhlobene, ukushisisa izinga lokushisa ngemva kokupholisa isifutho noma insimbi engagqwali forgings kukho konke ukupholisa medium quenching.

Ukushisa okungaguquki kunqunyelwe amandla emishini. Kwesinye isikhathi, ukuze kushiswe ama-forging ensimbi engagqwali adlula umkhawulo wamandla futhi afinyelele ukujula okuthile kongqimba oluqinile, kusetshenziswa ukushisa okuphindaphindiwe noma ukushisa kwangaphambili ku-600 ℃.

Ingenabalaizinsimbi zensimbiUkushisa okungeniswayo kusetshenziswa ukufudumeza kweselula okuqhubekayo kuvame kakhulu, ukufudumeza kokucisha imvamisa ephezulu kuvamise ukuba yinzwa engaguquki kanye ne-stainless steel forgings mobile. Ukushisisa kwefrikhwensi emaphakathi namandla, ngokuvamile ukuze kube nokunyakaza kwenzwa, ama-forging ensimbi engagqwali nawo angazungeziswa lapho kudingeka. I-inductor ifakwe etafuleni elinyakazayo lomshini wokucisha.

Ukushisa okucishayo kuncike ekukhethweni kwamandla kanye nesivinini esihambayo, ngoba indawo yokushisa eqhubekayo ehambayo incane, uhla lwezicelo lwe-stainless steel forgings lubanzi kakhulu, ngakho-ke okwamanje, ekushiseni kokungeniswa kwensimbi engagqwali ekhaya nakwamanye amazwe, ukusetshenziswa okujwayelekile kwamandla aphezulu okushisa okungeniswa kwamandla okuphansi.

Isikhathi sokuthumela: May-13-2021