1. ukubunjwa kwe-isothermalikwinkqubo yonke yokwenza ubushushu bebillet ukugcina ixabiso elingaguqukiyo.Isothermal forgingkukusebenzisa ngokupheleleyo iplastiki ephezulu yezinye isinyithi kwiqondo lobushushu elifanayo, okanye ukufumana i-microstructure ethile kunye neempawu. I-Isothermal forging ifuna ubushushu obuqhubekayo bokufa kunye ne-billet kunye, efuna iindleko eziphezulu kwaye isetyenziselwa kuphelaukubunjwa okukhethekileyoiinkqubo, ezifana nokwenziwa superplastic.

2.ukwenzaunokutshintsha isakhiwo sesinyithi, ukuphucula ukusebenza kwesinyithi. Emva kokoeshushu forging, i-cast cast yasekuqaleni, i-pores, i-micro-cracks kunye nokunye kuhlanganiswe okanye kufakwe i-welded; Iikristale ze-dendritic zangaphambili zophukile kwaye iinkozo ziba zilungile. Ngexesha elifanayo utshintshe ulwahlulo lokuqala lwe-carbide kunye nokusabalalisa okungalinganiyo, yenza i-uniform yesakhiwo, ukuze ufumane i-dense yangaphakathi, i-uniform, i-fine, ukusebenza kakuhle okubanzi, ukusetyenziswa okuthembekileyo kokubumba. Emva kokwenziwa kwe-deformation eshushu, isinyithi sisicubu se-fibrous; Emva kokuguqulwa okubandayo okubandayo, iikristale zentsimbi zibonisa ucwangco.

3. ukwenzakukwenza iplastiki yentsimbi ihambe kwaye wenze ubume obufunekayo bomsebenzi. Umthamo wesinyithi uhlala uhleli emva kokuhamba kweplastiki okubangelwa ngamandla angaphandle, kwaye isinyithi sihlala sigeleza kwinxalenye enobuncinci bokuchasana. Kwimveliso, i-workpiece shape isoloko ilawulwa ngokungqinelana nale migaqo ukuqonda umzobo ophazamisayo, ukwandisa umngxuma, ukugoba, ukuzoba kunye nokunye ukuguqulwa.

4. ukwenzangaphandle kobukhulu be-workpiece buchanekile, bulungele umbutho wemveliso yobuninzi.Yifa ngokukhohlisa, i-extrusion, isitampu kunye nezinye izicelo zobungakanani bokubumba obuchanekileyo, obuzinzileyo. Ubuchule obuphezulu bokubumba oomatshini kunye nomgca wemveliso wokuzenzela ngokuzenzekelayo unokusetyenziselwa ukuququzelela ukuveliswa kobuninzi okanye ukuveliswa kobuninzi.

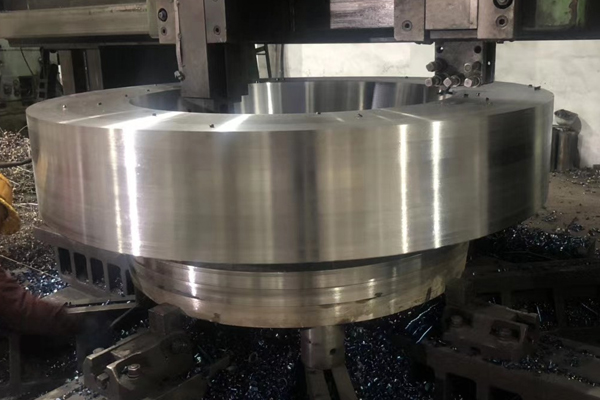

5. ukwenzainkqubo yokuvelisa ibandakanya ukuvala ibhillet,ukwenzaukufudumeza i-billet kunye nokulungiswa kwangaphambili ngaphambi kokwenza; Ukunyangwa kobushushu, ukucocwa, ukulinganisa kunye nokuhlolwa kwendawo yokusebenza emva kokwenziwa. Oomatshini bokubumba abaqhelekileyo abasetyenziswayo banehamile yokubumba, ucinezelo lwehydraulic kunye nomatshini wokushicilela. Ihamile yokubumba inesantya esinempembelelo enkulu, ehambelana nokuhamba kweplastiki yesinyithi, kodwa iya kuvelisa ukungcangcazela; I-Hydraulic press kunye ne-static forging, ilungele ukukhwabanisa ngesinyithi kunye nokuphucula umbutho, umsebenzi ozinzileyo, kodwa imveliso ephantsi; I-Mechanical press stroke ilungisiwe, kulula ukuyiqonda i-mechanization kunye ne-automation.

Kwilixa elizayo,ukwenzakunye nokucinezela itekhnoloji iya kuphuhlisa ukuphucula umgangatho wangaphakathi wokwenza kunye nokucinezela iinxalenye, ukuphuhlisa ukubunjwa okuchanekileyo kunye nokunyathela itekhnoloji, ukuphuhlisa izixhobo zokubumba kunye nokuvelisa umgca wemveliso kunye nemveliso ephezulu kunye ne-automation, ukuphuhlisa ukuguquguquka.ukwenzakunye nenkqubo ecinezelayo, phuhlisa entshaukwenzaizixhobo kunyeukwenzaiindlela zokulungisa. Ukuphucula umgangatho wangaphakathi weendawo zokubumba ikakhulu ukuphucula iimpawu zabo zomatshini (amandla, iplastiki, ukuqina, amandla okukhathala) kunye nokuthembeka. Oku kufuna usetyenziso olungcono lwethiyori yeplastiki yentsimbi; Ukusetyenziswa kwemathiriyeli esemgangathweni ongcono ngokwangaphakathi; Kulungileukulungiselela kwangaphambiliukufudumeza kunye nokwenza unyango lobushushu; Uvavanyo olungqongqo ngakumbi nolubanzi olungonakalisiyo lwamalungu okubumba.

Ixesha lokuposa: Oct-18-2021