1. Isothermal forgingkukugcina iqondo lobushushu lebillet lingaguquguquki ngexesha lonke lokwenziwa kwenkqubo.Isothermal forgingisetyenziselwa ukuthatha inzuzo yeplastiki ephezulu yeentsimbi ezithile kwiqondo lokushisa elingaguqukiyo okanye ukufumana izakhiwo kunye neempawu ezithile. Ukubunjwa kwe-Isothermal kufuna ukuba i-mold kunye ne-billet igcinwe kwiqondo lokushisa rhoqo kunye, elifuna ixabiso eliphezulu kwaye lisetyenziselwa kuphela iinkqubo ezikhethekileyo zokubumba kunye nokucinezela, ezifana nokuqulunqwa kwe-superplastic.

2. Ukuqulunqaunokutshintsha isakhiwo sesinyithi kunye nokuphucula ukusebenza kwesinyithi. Emva kokoeshushu forgingi-ingot, i-original cast state of loose, pore, i-micro crack idityanisiwe okanye i-welded; Ikristale yokuqala yedendritic yaphukile ukwenza iinkozo zibe zilungile. Ngelo xesha, tshintsha ulwahlulo lwe-carbide yasekuqaleni kunye nokusabalalisa okungalinganiyo, ukwenzela ukuba umbutho ufanane, ukuze ufumane i-dense yangaphakathi, i-uniform, i-fine, ukusebenza kakuhle okubanzi, ukusetyenziswa okuthembekileyo kwe-forgings. Emva kokoeshushu forgingdeformation, isinyithi isakhiwo fibrous; Emva kwe-deformation yokubumba ebandayo, iikristale zetsimbi zibonisa ukucwangciswa.

3.ukwenzakukwenza ukuba iplastiki yentsimbi ihambe kwaye yenziwe ibe yimilo efunekayo yomsebenzi. Umthamo wesinyithi awutshintshi emva kokuhamba kweplastiki ngamandla angaphandle, kwaye isinyithi sihlala sihamba sihamba ukuya kwindawo encinci yokuchasana. Kwimveliso, imilo ye-workpiece isoloko ilawulwa ngokwale mithetho, kwaye ukuguqulwa komzobo ophazamisayo, ukubuyisela, ukugoba kunye nomzobo onzulu kuyenzeka.

4.iumsebenzi wokwakhaubungakanani buchanekile, bulungele umbutho wemveliso yobuninzi.Yifa ngokukhohlisa, i-extrusion, i-stamping kunye nezinye izicelo ze-mold forming size ichanekile kwaye izinzile. Oomatshini bokubumba obuphezulu kunye nomgca wemveliso wokuzenzela ngokuzenzekelayo unokusetyenziselwa ukuququzelela ukuveliswa kobuninzi obukhethekileyo okanye ukuveliswa kobuninzi.

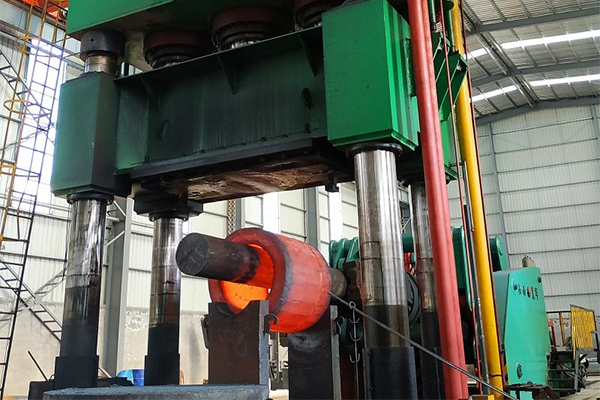

5.Inkqubo yemveliso yeukwenzaibandakanya ukugquma, ukufudumeza kunye nokunyangwa kwangaphambili kokubumba into engenanto phambi kokwenza; Ukunyangwa kobushushu, ukucocwa, ukulinganisa kunye nokuhlolwa kwendawo yokusebenza emva kokwenziwa. Oomatshini bokubumba abaqhelekileyo abasetyenziswayo banehamile yokubumba, ucinezelo lwehydraulic kunye nomatshini wokushicilela. Ihamile yokubumba inesantya esikhulu sempembelelo, ehambelana nokuhamba kweplastiki yesinyithi, kodwa iya kuvelisa ukungcangcazela; Umshicileli we-hydraulic usebenzisa i-static forging, inenzuzo kwi-forging ngokusebenzisa isinyithi kunye nombutho wokuphucula, umsebenzi uzinzile, kodwa imveliso iphantsi; Umshicileli womatshini une-stroke esisigxina, ekulula ukuyiqonda i-mechanization kunye ne-automation.

Kwixesha elizayo, iiteknoloji yokwenzaiya kuphucula umgangatho wangaphakathi weiindawo zokubumba, phuhlisa ukuchanekaukwenzakunye nobuchwephesha bokucofa isitampu, phuhlisaizixhobo zokubumbakwayeukuvelisa imvelisoihambelana nemveliso ephezulu kunye neqondo lokuzenzekelayo, ukuphuhlisabhetyebhetye forgingukwenza inkqubo, nokuphuhlisa entshaizinto zokwakhakwayeukuqulunqa inkquboiindlela. Ukuphucula umgangatho wangaphakathi weforgings, ikakhulu ukuphucula iimpawu zabo zomatshini (amandla, iplastiki, ukuqina, amandla okukhathala) kunye nokuthembeka. Oku kufuna usetyenziso olungcono lwethiyori yeplastiki yentsimbi; Faka imathiriyeli esemgangathweni ongcono ngokwangaphakathi; Lungiselela ukufudumeza kwangaphambili kunye nokulungiswa kobushushu; Uvavanyo olungqongqo ngakumbi nolubanzi olungonakalisiyo lwe-forgings.

Ixesha lokuposa: Jan-25-2021