Iizinto zokwakhaubukhulu becala ziyintsimbi yekhabhoni kunye nentsimbi yealloyi, ilandelwa yi-aluminiyam, i-magnesium, ubhedu, i-titanium kunye neengxube zazo. Imeko yokuqala yezinto eziphathekayo yibha, ingot, umgubo wesinyithi kunye nentsimbi engamanzi. Umlinganiselo wommandla we-cross-sectional wentsimbi ngaphambi nasemva kokuguqulwa kubizwa ngokuba yi-ukubunjwa ratio. Ukhetho oluchanekileyo lweukubunjwa ratio, ubushushu obufanelekileyo bokufudumeza kunye nexesha lokubamba, ubushushu bokuqala bokubumba kunye nobushushu bokugqibela bokubumba, umlinganiselo ofanelekileyo we-deformation kunye ne-deformation speed inempembelelo enkulu ekuphuculeni umgangatho wemveliso kunye nokunciphisa iindleko.

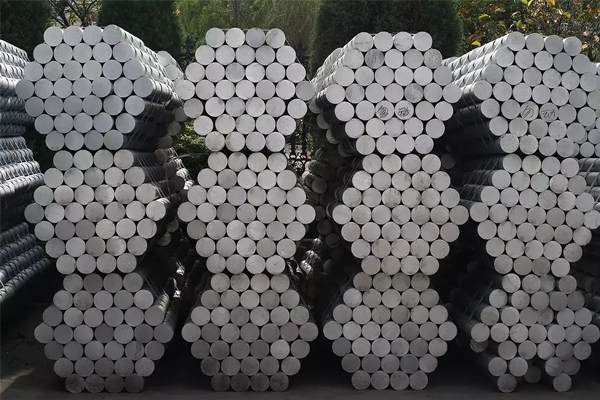

Ngokubanzi encinci kunyeforgings mediumzingqukuva okanye imivalo yesikwere njengeebhilithi. Imivalo inesakhiwo esifanayo sokutya okuziinkozo kunye neempawu ezilungileyo zoomatshini, imilo echanekileyo kunye nobukhulu, umgangatho olungileyo womphezulu, ulungele imveliso yobuninzi. Ngethuba nje ubushushu bokufudumala kunye neemeko zokuguqulwa zilawulwa ngokufanelekileyo, kulungileforgingsinokwenziwa ngaphandleimveliso enkuludeformation.

Ingot isetyenziselwa kuphelaiifolishi ezinkulu. I-ingot yisakhiwo se-as-cast kunye neekristale ezinkulu zekholomu kunye namaziko akhululekile. Ke ngoko, iikristale zekholomu kufuneka ziphulwe zibe ziinkozo ezintle ngokusebenzisa i-deformation enkulu yeplastiki, kwaye ukuxinezeleka okuxekekileyo kunokufumana ubume bentsimbi obugqwesileyo kunye neempawu zoomatshini.

Ukwenziwa komgubo kunokwenziwa kwifomati eyenziwe ngaphambili eyenziwe ngumgubo wesinyithi emva kokucinezela kunye nokudubula phantsi kwemeko eshushu ngu.kufa ukwenzangaphandle kokuqhwaba.Forgingsumgubo usondele kubuninzi bezinto eziqhelekileyoukufa forgings, kunye neempawu ezintle zoomatshini kunye nokuchaneka okuphezulu, okunokunciphisa ukusika okulandelayo. Ukufakwa kwepowder kunye nesakhiwo sangaphakathi esifanayo kwaye akukho lucalucalulo lunokusetyenziswa ukwenza iigiya ezincinci kunye nezinye izinto zokusebenza. Nangona kunjalo, ixabiso lepowder liphezulu kakhulu kunebhar eqhelekileyo, ngoko ke ukusetyenziswa kwayo kwimveliso kulinganiselwe. ,

Ubume obufunwayo kunye neempawu zeukufa forgingsinokufumaneka ngokufaka uxinzelelo olusisigxina kwintsimbi engamanzi egalela kwigumbi lokufa ukuze iqiniswe, icwebezelise, iqukuqelele, ideformation yeplastiki kunye nefom phantsi kwesenzo soxinzelelo. Ulwelo lwesinyithi sokwenziwa kwesinyithi yindlela yokubumba phakathi kokuphosa ukufa kunye ne-dieforging, ngakumbi ilungele iindawo ezintsonkothileyo ezinodonga olunzima ukuba zenziwe ziqhelekileyo.kufa ukwenza.

Ukuqulunqaizixhobo ukongeza kwizinto eziqhelekileyo, ezifana nokwakheka ezahlukeneyo carbon steel kunye nentsimbi ingxubevange, ilandelwa yi aluminiyam, magnesium, ubhedu, titanium kunye nengxubevange yayo, ubushushu obuphezulu intsimbi base ingxubevange, nickel base superalloy, cobalt-based superalloy deformation yealloyi kwakhona ISEBENZA forging okanye indlela yokuqengqeleka, kuphela ingxubevange ngenxa yommandla wayo emxinwa yeplastiki, ngoko keukwenzaubunzima buya kuba bukhulu ngokwentelekiso, Izinto ezahlukeneyo zokufudumeza ubushushu, ubushushu obuvulekileyo bokubumba kunye nobushushu bokugqibela bokubumba zineemfuno ezingqongqo.

Ixesha lokuposa: Mar-14-2022