I-flat welding flangengokuthanda kwakhoukwenzaUkufa kwentshukumo, inokwahlulwa ibe yi-swing rolling, swing rotaryukwenza, ukubumba umqulu, ukuqengqeleka kwewedge, ukuqengqeleka kweringi, ukuqengqeleka, njalo njalo. Ukubunjwa okuchanekileyo kunokusetyenziswa kwakhona ekujikeni, ukujikeleza okujikelezayo kunye nokuqengqeleka kweringi. Ukubumba umqulu kunye nokuqengqeleka komnqamlezo kunokusetyenziswa njengonyango lwangaphambili lwemathiriyeli ebhityileyo ukuphucula ukusetyenziswa kwemathiriyeli. Njengokwenza ngokukhululekileyo, i-rotary forging yenziwe ngokuyinxenye kwaye inenzuzo yokwenza nokuba amandla okubumba angaphantsi kobukhulu bokubumba. Ukuqulunqwa okuyinkimbinkimbi kunokugqitywa kwinkqubo enye okanye ngaphezulu. Ngenxa yokuba akukho miphetho ye-burr, indawo yokubeka i-forging iyancipha kwaye umthwalo ofunekayo uyancitshiswa.

Okuukwenzaindlela ibangela ukuba impahla yande ukusuka kufutshane neflange xa isenziwa ngoomatshini. Ngenxa yokuba umgama phakathi kwendawo yokufa kunye nendawo yamahhala yahlukile, kunzima ukuqinisekisa ukuchaneka. Ke ngoko, ngokulawula intshukumo yentshukumo yokufa kunye nenkqubo yokujikeleza ejikelezayo ngekhompyuter, iimveliso ezinemilo entsonkothileyo kunye nokuchaneka okuphezulu kunokuveliswa. Ewe, ndingayenza. Ifunyenwe ngamandla asezantsi okwenza. Amagqabi e-Steam turbine kunye nezinye iintlobo kunye nobukhulu obukhuluforgingsimveliso.

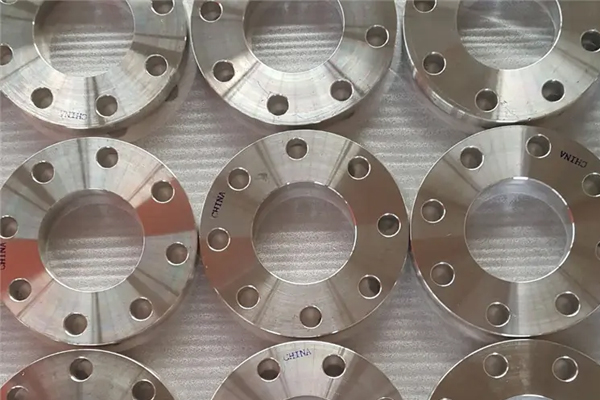

I-flat welding flange ukwenzaingahlulwa ibe simahlaukwenza, ukucaphukisa, ukukhupha, ukufakela, ukufakela ukufa okuvaliweyo kunye nokuvala ukuphazamisa ukufakela. Ngokuqhelekileyo, ukubumba kwiqondo lokushisa kwe-recrystallization kubizwa ngokuba yi-hot forging, kwiqondo lokushisa ngaphandle kokufudumeza ukufudumala kubizwa ngokuba yi-cold forging. Niniiiflange eziphothiweyoziyenzekilekwiqondo lobushushu eliphantsi, imilinganiselo yeforgingskunzima ukutshintsha. Xa yenziwe ngaphantsi kwe-700 ℃, phantse akukho sikali se-oxide esenziwayo kwaye akukho decarburization yomphezulu eyenzekayo.

I-flat welding flangeumgaqo wokutywina: imigangatho emibini yokutywina yeebholiti cinezela igasket yeflange ukwenza itywina, enokuthi ikhokelele kumonakalo wokutywinwa. Ukuze kugcinwe itywina, kuyimfuneko ukugcina i-bolt force enkulu, ngoko ukwandisa i-bolt. Iibholiti ezinkulu kufuneka zihambelane namantongomane amakhulu. Oku kuthetha ukuba uya kufuna iibholiti ezinkulu zedayamitha ukudala iimeko zokuqinisa i-nut.

Inqaku leflat welding flange

1. Ipleyiti yentsimbi esetyenziselwa ukwenziwaiiflange eziphothiweyoyenziwe kwaye isetyenziswe ngokuhlolwa kwe-ultrasonic ngaphandle kwe-delamination, ukwenzela ukuchonga umgangatho omhle kunye neengxaki zokusebenza, kwaye zenziwe kwaye zivavanywe ngokweemfuno ezithile zekhwalithi, i-steel plate ayinayo iingxaki zekhwalithi.

2. Insimbi inqunyulwa ibe yimichilo ecaleni kwendlela yokujikeleza, kwaye emva koko igobile kwaye i-butt ifakwe kwiindandatho, yenza indawo ejikelezayo kwintsimbi. Isilinda. Ekwenziweni kweeflange ezine-welding flat, ipleyiti yensimbi ayifanele ifakwe ngokuthe ngqo kwi-flange yentamo, kodwa kunokuba yenziwe kwaye isetyenziswe ngobuchule obuthile.

Ixesha lokuposa: Jun-13-2022