Ngokwesantya sokupholisa esahlukileyo, kukho iindlela ezintathu zokupholisa ze-stainlessizixhobo zentsimbi: ukupholisa emoyeni, isantya sokupholisa sikhawuleza; Isantya sokupholisa siyacotha esantini; Ukupholisa kwisithando somlilo, izinga lokupholisa lelona licothayo.

1. Ukupholisa emoyeni. Emva kokoukwenza, engenabalaizixhobo zentsimbizibekwe ngokuthe ngqo kumgangatho weworkshop zokupholisa kwiziqwenga ezingatshatanga okanye kwiimfumba, kodwa hayi kumhlaba omanzi okanye ipleyiti yesinyithi, okanye kwindawo enokutsalwa, ukuze kuthintelwe ukupholisa okungalinganiyo okanye ukupholisa ngokukhawuleza kwendawo okubangela iintanda.

2. Ukupholisa kwi-ash eyomileyo kunye nomngxuma wesanti (ibhokisi), ubushushu besanti yentsimbi jikelele kufuneka bungabi ngaphantsi kwama-500 ℃, uthuthu olujikelezileyo kunye nobukhulu besanti abukho ngaphantsi kwe-80mm.

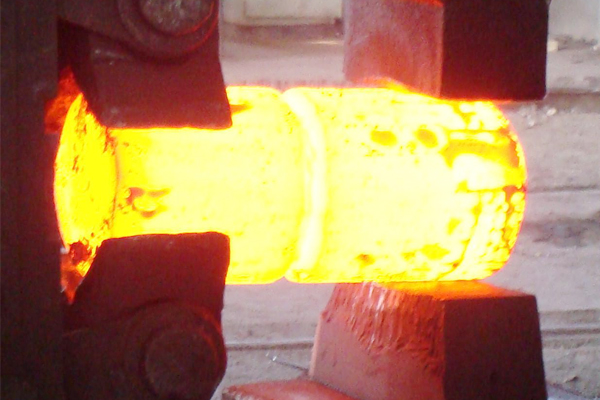

3. Ukupholisa kwisithando somlilo, i-stainlessizixhobo zentsimbizifakwa ngqo kwiziko ukuze zizipholise emva kokubunjwa. Ukushisa kweengxenye zetsimbi kwisithando somlilo akufanele kube ngaphantsi kwe-600-650 ℃, kwaye iqondo lokushisa le-stainless steel forgings kwisithando somlilo lilingana nesithando somlilo. Ngenxa yokuba isantya sokupholisa i-stainless steel forgings inokulawulwa ngokulungiswa kweqondo lokushisa lesithando somlilo, ifanelekile ukupholisa emva kokupholisa kwentsimbi ephezulu ye-alloy, i-alloy forgings ekhethekileyo kunye ne-forgings enkulu yensimbi engenasici.

Ingenabalaizixhobo zentsimbiiindlela zokufudumeza umphezulu we-induction zineentlobo ezimbini: i-mobile eqhubekayo kunye ne-fixed, indlela eqhubekayo ehambayo yinzwa okanye i-stainless steel forgings yokufudumeza kunye nokuhamba kwinkqubo yokupholisa kunye nokucima okulandelwa ngumphetho. Kwaye i-fixed stainlessizixhobo zentsimbiukufudumeza indawo yokucima kwi-sensor, i-sensor kunye ne-stainless steel forgings ayinayo intshukumo ehambelanayo, ukuba ifudunyezwe kwiqondo lokushisa emva kokupholisa isitshizi okanye i-stainless steel forgings kuyo yonke i-medium medium quenching.

Ukufudumala okuzinzileyo kukhawulelwe ngamandla ezixhobo. Ngamanye amaxesha, ukwenzela ukutshisa i-forging yensimbi engenasici edlula umda wamandla kwaye ifike kubunzulu obuthile bomgangatho oqinileyo, ukufudumeza okuphindaphindiweyo okanye ukufudumeza kwangaphambili ukuya kwi-600 ℃ kusetyenziswa.

Ingenabalaizixhobo zentsimbiUkufudumeza kwe-induction usebenzisa ukufudumeza okuqhubekayo okuhambayo kuxhaphake kakhulu, ukufudumeza okuphakamileyo kokucinywa kwe-frequency kuqhelekile kwinzwa esisigxina kunye ne-stainless steel forgings mobile. Ukufudumeza okuphakathi kunye nokufudumeza amandla, rhoqo ukuya kwintshukumo yenzwa, i-forging yensimbi engenasici nako kunokujikeleziswa xa kuyimfuneko. I-inductor ifakwe kwitafile eshukumayo yomatshini wokucima.

Ukucima iqondo lokushisa kuxhomekeke ekukhethweni kwamandla kunye nesantya esihambayo, kuba indawo eqhubekayo yokufudumeza incinci, uluhlu lwesicelo se-stainless steel forgings lubanzi kakhulu, ngoko ke ngoku, ekufudumeni kwe-induction ye-stainless steel forgings ekhaya nakwamanye amazwe, ukusetyenziswa ngokubanzi kwamandla aphezulu okufudumala indlela yokufudumeza ephantsi.

Ixesha lokuposa: May-13-2021