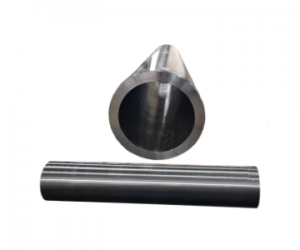

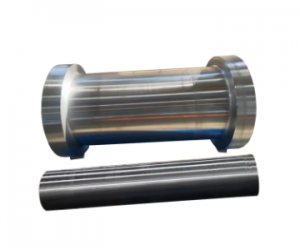

Tube Forging Hollow Bars

Product Details:

Place of Origin: Shanxi

Brand Name: DHDZ

Certification: ASME, JIS, DIN, GB, BS, EN, AS, SABS, ASTM A370, API 6B, API 6C

Testing Report: MTC, HT, UT, MPT, Dimension Report, Visual Test, EN10204-3.1, EN10204-3.2

Specification: TUV/ PED 2014/68/EU

Minimum Order Quantity: 1 piece

Transport Package: Plywood Case

Surface Treatment: Polishing

Price: Negotiable

Production Capacity: 20000 Ton/ Year

|

Material elements |

C |

Mn |

P |

S |

SI |

Cr |

NI |

Mo |

Cu |

N |

|

A182 F51 |

≤ 0.030 |

2.0 |

≤ 0.030 |

≤ 0.020 |

<0.80 |

21-23 |

4.5-6.5 |

2.50-3.50 |

/ |

0.20-0.24 |

|

A182 F53 |

≤ 0.030 |

≤ 1.20 |

≤ 0.035 |

<0.020 |

<0.80 |

24-26 |

6.0-8.0 |

3-5 |

<0.50 |

0.24-0.32 |

|

34CrNiMo6 |

0.3-0.38 |

0.5-0.8 |

≤ 0.025 |

≤ 0.035 |

≤ 0.4 |

1.3-1.7 |

1.3-1.7 |

0.15-0.3 |

/ |

/ |

|

16MnD |

0.13-0.20 |

1.2-1.6 |

≤0.030 |

≤0.030 |

0.17-0.37 |

≤0.30 |

≤0.30 |

/ |

/ |

/ |

|

20MnMo |

0.17-0.23 |

1.1-1.4 |

≤0.025 |

≤0.015 |

0.17-0.37 |

≤0.030 |

≤0.030 |

0.20-0.35 |

/ |

/ |

|

20MnMoNo |

0.16-0.23 |

1.2-1.5 |

≤0.035 |

≤0.035 |

0.17-0.37 |

/ |

/ |

0.45-0.60 |

/ |

0.20-0.45 |

| Mechanical property | Dia.(mm) | TS/Rm (Mpa) | YS/Rp0.2 (Mpa) | EL/A5 (%) | RA/Z (%) | Notch | Impact energy | HBW |

| A182 F51 | / | ≥620 | ≥450 | ≥25 | >45 | V | ≥45J | / |

| A182 F53 | / | ≥800 | ≥550 | ≥15 | / | V | / | <310 |

| 34CrNiMo6 | Ф12.5 | ≥785 | / | ≥11 | ≥30 | V | ≥71J |

/ |

| 16MnD | Ф10 | 470-630 | ≥345 | ≥21 | / | V | / |

/ |

| 20MnMo | Ф10 | ≥605 | ≥475 | ≥25 | / | V | ≥180 |

/ |

| 20MnMoNo | Ф10 | ≥635 | ≥490 | ≥15 | / | U | ≥47 |

187-229 |

Production Procedures:

Forging process flow quality control: Raw material steel ingot into warehouse(test the chemical content) → Cutting→ Heating(Furnace temperature test) → Heat treatment after forging(Furnace temperature test) Discharge the furnace(blank inspection)→ Machining→ Inspection(UT,MT,Visal diamention, hardness)→ QT→ Inspection(UT, mechanical properties, hardness, grain size)→ Finish machining→ Inspection (dimension)→ Packing and Marking(steel stamp, mark)→ Storage Shipment

Advantage:

Excellent mechanical properties,

High-precision dimensional tolerance,

Control the production procedure strictly,

Advanced manufacture equipment and inspection devices,

Excellent technical personality,

Produce different dimension based on customer’ s requirements,

Pay attention on the package protection,

Quality full service.

Application Industries:

Metallurgical equipment, mining equipment, offshore vessels, lifting equipment, construction machinery, power generation, etc.