Flat welding flange and pipeline accessories procurement is inseparable. Today, I will introduce flat welding flanges for you in detail, so that customers have a better understanding of flat welding flanges, so that it is easy to buy.

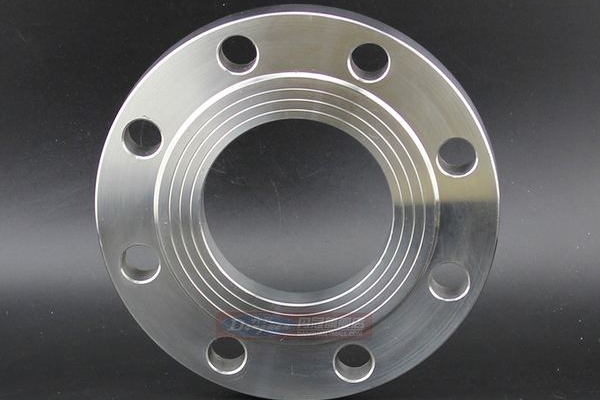

A: flat welding flange refers to a flange connected with the container or pipe by fillet welding. It is arbitrary flange. Check integral flange or loose flange according to the integrity of flange ring and straight pipe section at design time. There are two types of flange rings with and without neck. Compared with the neck butt welding flange, the flat welding flange is simple in structure and saves material, but the rigidity and sealing is not as good as the neck butt welding flange. Flat welded flanges are widely used to connect medium and low pressure vessels and pipelines.

Two: the characteristics of flat welding flange: flat welding flange can at least save space and reduce weight, more importantly, to ensure that the joint will not leak and have good sealing performance. Therefore, flange gaskets have been replaced by sealing rings to ensure that the sealing surface matches the sealing surface. In this way, only a small amount of pressure is required to compress the seal cap. In order to reduce the required pressure reduction, the size and number of bolts can be subdivided accordingly, so the result is a new product that is small in size and light in weight (70 to 80 percent lighter than conventional flanges). Therefore, flat welding flange is a relatively high quality flat welding flange products, reduces the quality and space, and plays an important role in industrial applications.

Three: flat welding flange sealing principle: the two sealing surfaces of the bolts squeeze the flange gasket and form a seal, which also leads to the destruction of the seal. In order to maintain the seal, great bolt force must be maintained. Therefore, the bolt must be made into diameter. The size of the bolt needs to complement the diameter of the nut, which means that the diameter of the bolt is needed to create the conditions used to tighten the nut. However, the diameter and size of the bolts, the applicable method and the entire installation will require enormous size and weight. This creates a particular problem in the Marine environment, where weight is always the main concern one must be aware of. And, basically, flat welded flanges are ineffective seals. 50% of the bolt load is required to be used as the extrusion gasket, while only 50% of the load is required to maintain the pressure.

Flat welded flanges are suitable for piping systems with low pressure levels and less pressure fluctuation, vibration and shock. Flat-welded flanges have the advantage that they are easier to align during welding and assembly and are relatively inexpensive, so they have become widely used.

Post time: Dec-30-2021